Precipitate containing sewage separating machine

A separator and sediment technology, applied in the field of separators, can solve problems such as waste of water resources, environmental pollution, lack of recycling, etc., and achieve the effect of improving water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

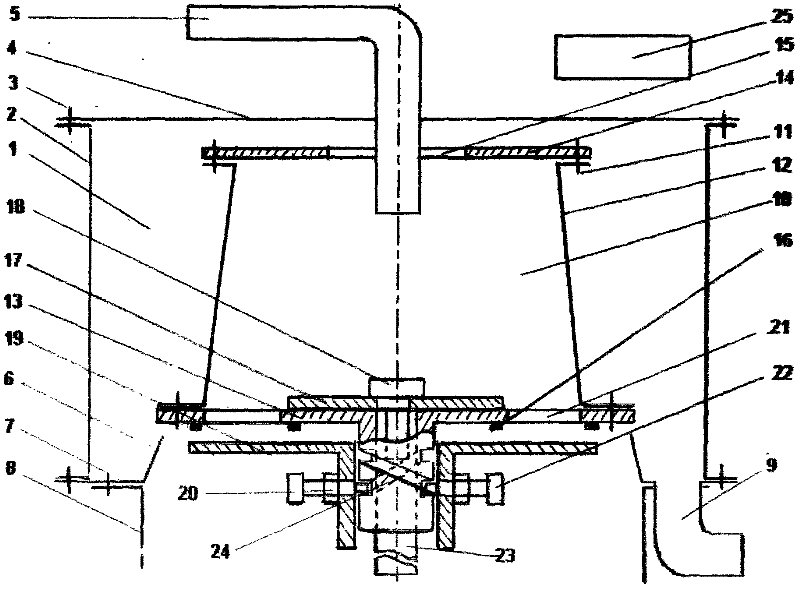

[0012] Specific embodiment one: with reference to accompanying drawing of description. Start the motor during use, if at this moment the direction of rotation of the motor rotor is forward rotation, then the rotating shaft (23) also rotates in the forward direction. Screw convex shaft (22), the effect of 2 same direction slope track grooves (24) that are symmetrical with the separation bucket base (13) center cover position, impels the automatic sealing cover (19) to advance upwards, and the separation bucket base (13) ) in close contact with the two sealing rings (16) at the bottom of the separation barrel (10) to seal the bottom of the separation barrel (10); the sewage containing sediment flowing into the separation barrel (10) from the sewage input pipe (5) is Throw it to the inner wall around the body of the separation barrel (12), and the material with a larger specific gravity than water is adsorbed on the inner wall around it, and the water is thrown from the surroundi...

specific Embodiment 2

[0013] Specific embodiment two: for the sake of simplicity, judge whether the sediment accumulation in the separation bucket reaches the rated capacity by observing the turbidity of the water discharged after separation, and use the manual method to control the positive and negative rotation of the motor, and automatically control the System (25) is removed, same as above-mentioned " specific embodiment one ", can obtain above-mentioned separating effect equally.

[0014] The present invention effectively overcomes the disadvantages of the prior art that it takes a large area of land to build a sedimentation tank and requires long-term sedimentation for the treatment of sewage containing sediment, and can separate the sediment and water in the sewage containing sediment in an instant. Not only is it easy to use, low in investment costs, it saves a large area of sedimentation tank land and wins time, and its water can be retransmitted to the production water that produces th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com