Method for treating reverse osmosis concentrated water

A reverse osmosis concentrated water and treatment method technology, applied in the field of reverse osmosis concentrated water treatment, can solve problems affecting the application of reverse osmosis technology, organic matter content reduction, salt reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

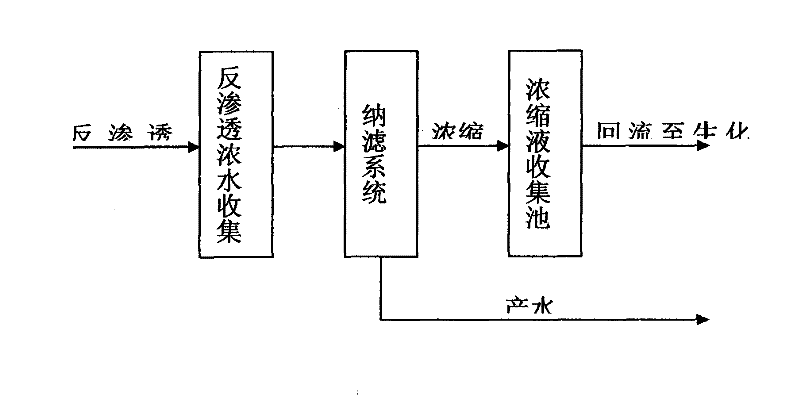

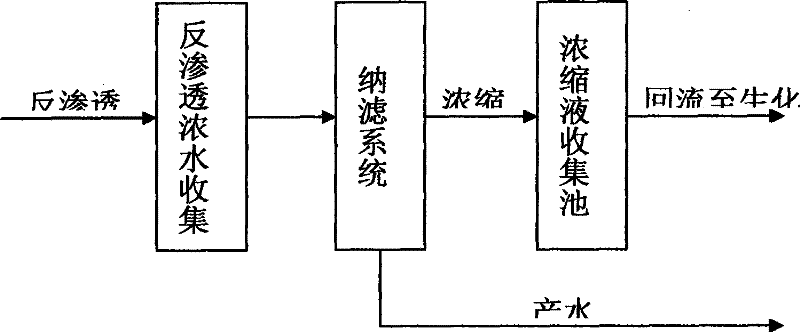

Image

Examples

Embodiment 1

[0023] The effluent of a refinery’s production wastewater after secondary biochemical treatment is further treated and reused by adding alkali to remove hardness-ultrafiltration-reverse osmosis process. The pH of the reverse osmosis concentrated water is 8.3, the COD is 190mg / L, and the conductivity It is 4600μm / cm, and the total hardness is 213mg / L (as CaCO 3 count).

[0024] The above-mentioned concentrated water is treated by a nanofiltration system. The operating conditions of the nanofiltration system are as follows: the nanofiltration membrane is selected as Dow FILMEC TM NF270-400. The operating conditions are: the pressure is 0.6MPa, the pH is adjusted to 6.8, and the temperature is 20°C. Under these operating conditions, the recovery rate of the control membrane is 70%, and the permeation flux of the membrane is 19L / m 2 h.

[0025] After nanofiltration membrane treatment, the concentrated solution has a COD of 532mg / L, a conductivity of 11600μm / cm, and a total har...

Embodiment 2

[0028] The discharge water from a refinery’s production wastewater after the secondary biochemical treatment is advanced treated and reused by the multi-media filtration-ultrafiltration-reverse osmosis process. The pH of the reverse osmosis concentrated water is 7.6, the COD is 155mg / L, and the conductivity is 3700μm / cm, total hardness 426mg / L (as CaCO 3 count).

[0029] The above-mentioned concentrated water is treated by a nanofiltration system. The operating conditions of the nanofiltration system are as follows: the nanofiltration membrane is selected as Dow FILMEC TM NF200-400. The operating conditions are: the pressure is 0.5MPa, the pH is adjusted to 7.0, and the temperature is 20°C. Under this operating condition, the recovery rate of the control membrane is 70%, and the permeation flux of the membrane is 20L / m 2 h.

[0030] After nanofiltration membrane treatment, the concentrated solution has a COD of 463mg / L, a conductivity of 10300μm / cm, and a total hardness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com