Nano silicon dioxide modified hard wood wax oil and preparation method thereof

A nano-silica, hard wood technology, applied in wax coatings, polyester coatings, coatings, etc., can solve the problems of peeling or scratching of the paint film, low hardness of the dry film of the coating, expansion deformation and cracking, etc. The effect of accelerating release, high porosity, and accelerating oxygen absorption polymerization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

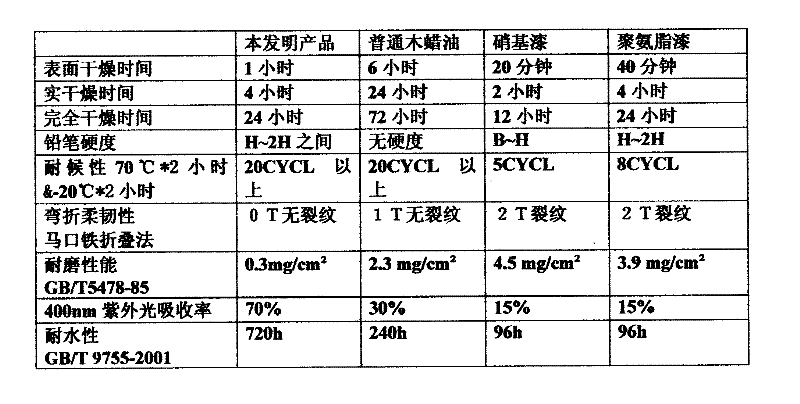

[0043] Example 1, see figure 1 . The present embodiment is a preferred embodiment, that is, a kind of matt nano-silica modified hard wood wax oil, the raw materials it includes and its weight percent content are:

[0044] Hard tung oil or linseed oil 36%,

[0045] Carnauba wax with a softening point between 85°C and 95°C

[0046] 17%,

[0047] The oil length is 78%-80%, and the solid content is more than 98% of linseed oil long oil alkyd resin

[0048] 17%,

[0049] Nano silica 3% with a particle size between 60-80nm,

[0050] Aromatic hydrocarbons with a distillation range between 160-200° 25.0%

[0051] Isooctanoate compound drier 1.7%,

[0052] Methyl ethyl ketone oxime 0.3%.

[0053] The performance comparison table between this product and ordinary wood wax oil / nitro paint / polyurethane paint figure 1 .

Embodiment 2

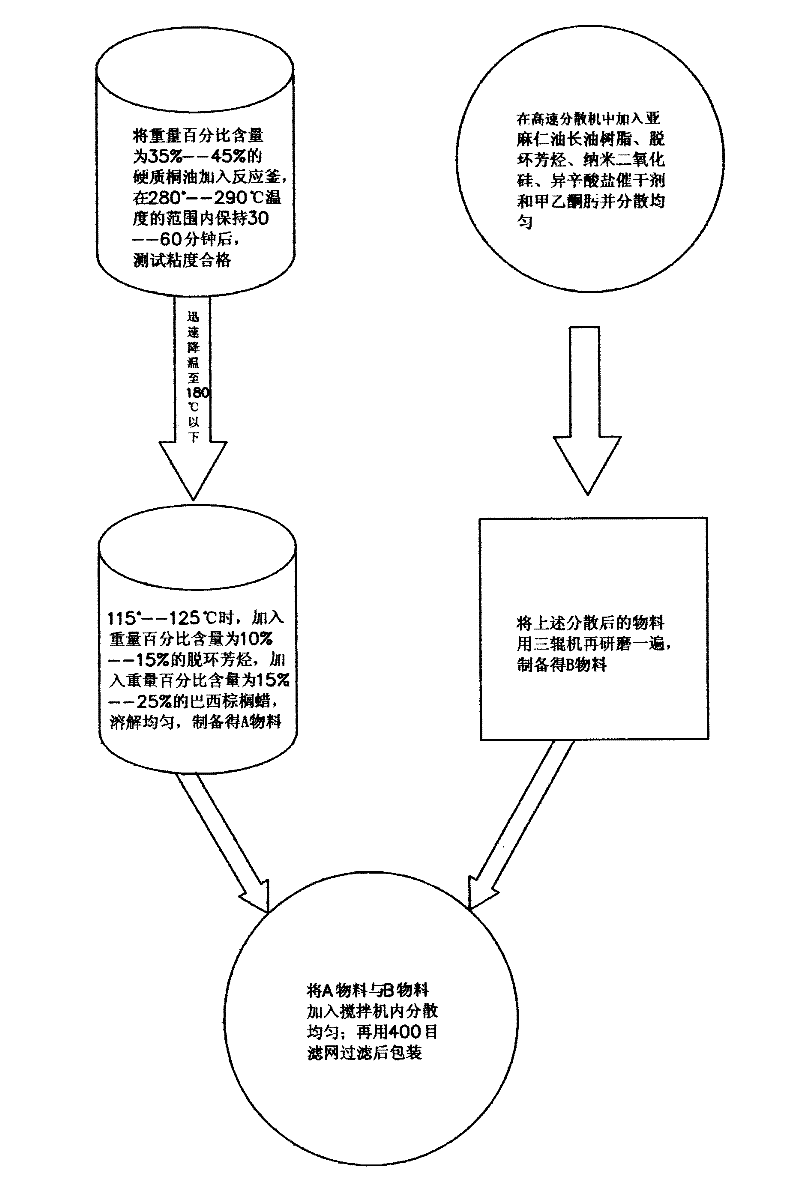

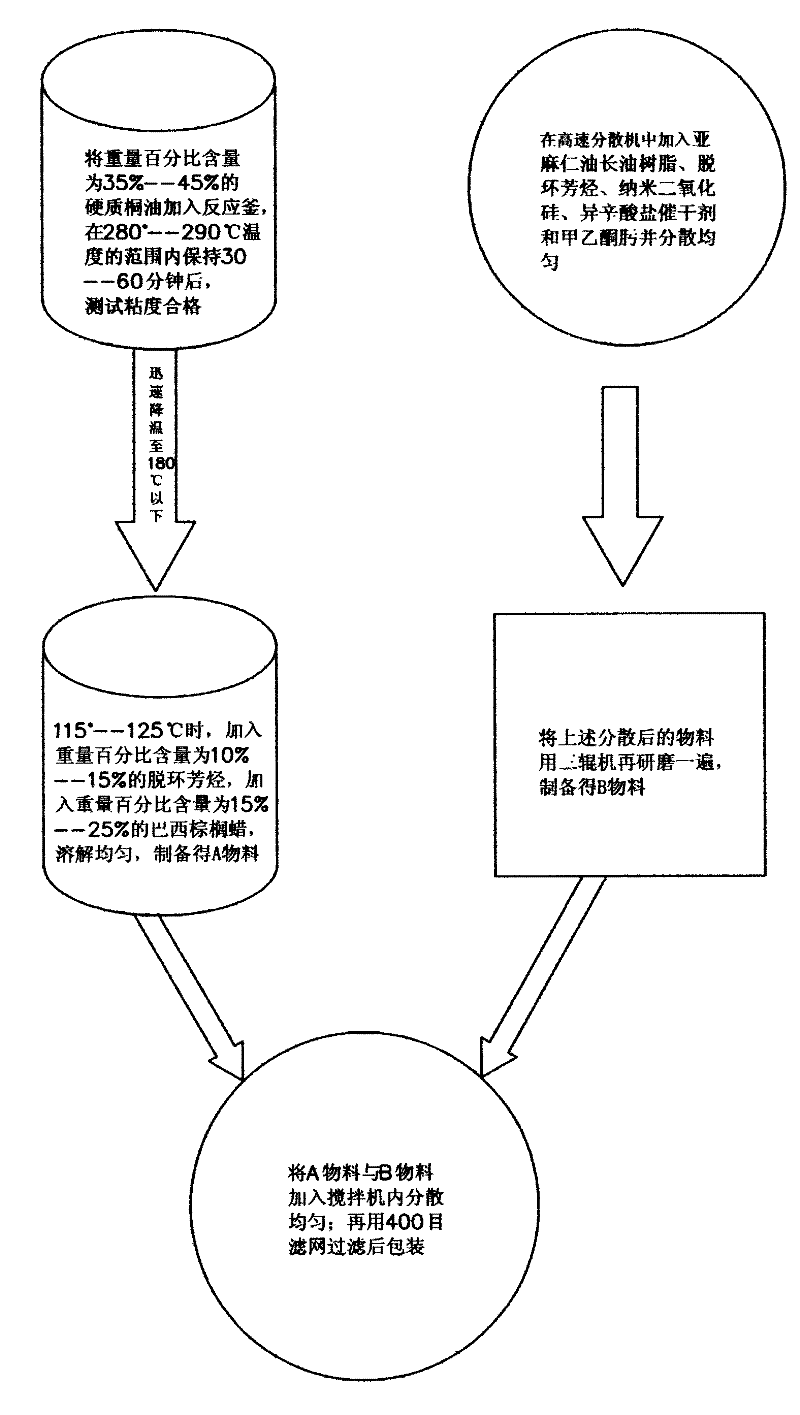

[0054] Example 2, see figure 2 . The method for making product of the present invention comprises the following steps:

[0055] The first step is to prepare material A:

[0056] (1) The hard tung oil that is 36% by weight percentage content is added to reactor, after keeping 30-60 minute in the scope of 280 °-290 ℃ of temperature, when testing viscosity in the scope of 6-10Pa.s, rapidly cool down to Below 180℃;

[0057] (2) When the temperature drops to 115°-125° C., add decyclic aromatic hydrocarbons with a weight percentage content of 12%, and add carnauba wax with a weight percentage content of 17%, and cool down and leave the kettle after the dissolution is complete;

[0058] The second step is to prepare material B:

[0059] (1) the linseed oil long oleoresin that the weight percent content is 17% joins in the high-speed disperser;

[0060] (2) In the above-mentioned high-speed disperser, adding a decyclic aromatic hydrocarbon with a weight percent content of 13% is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com