Energy-free automatic drainage machine and drainage device thereof

A technology of automatic drainage and drainage machine, which is applied to machines/engines, water conservancy projects, mechanical equipment, etc., can solve the problems of doubling the weight of pipes, cannot be used, and inconvenient installation, and achieves energy saving, good applicability, and convenient installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

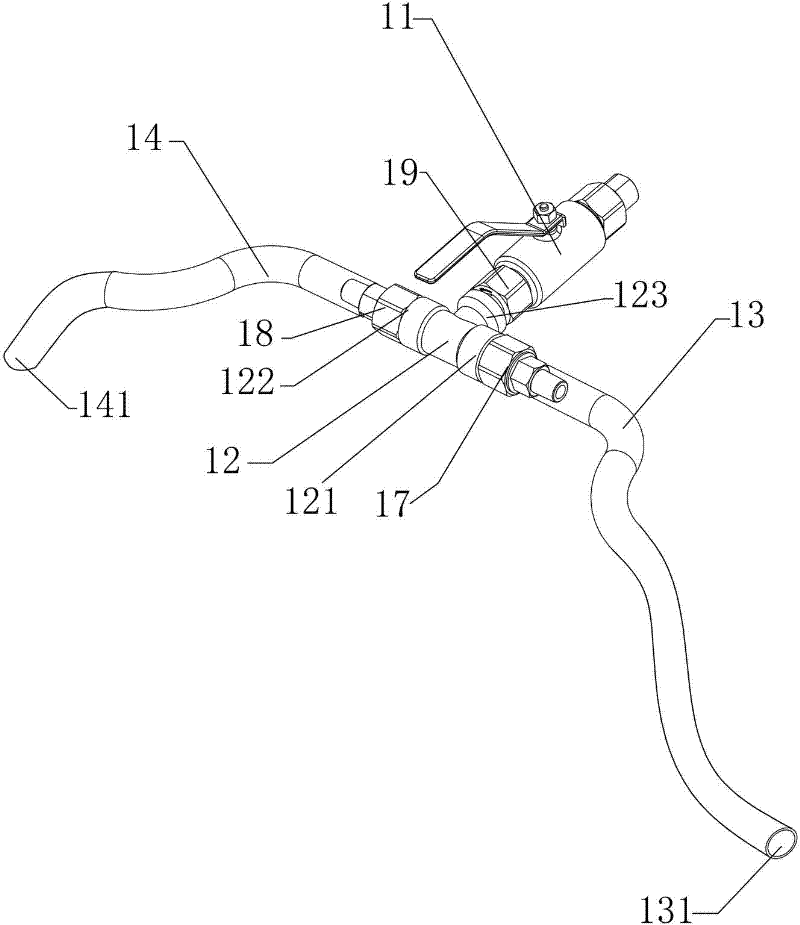

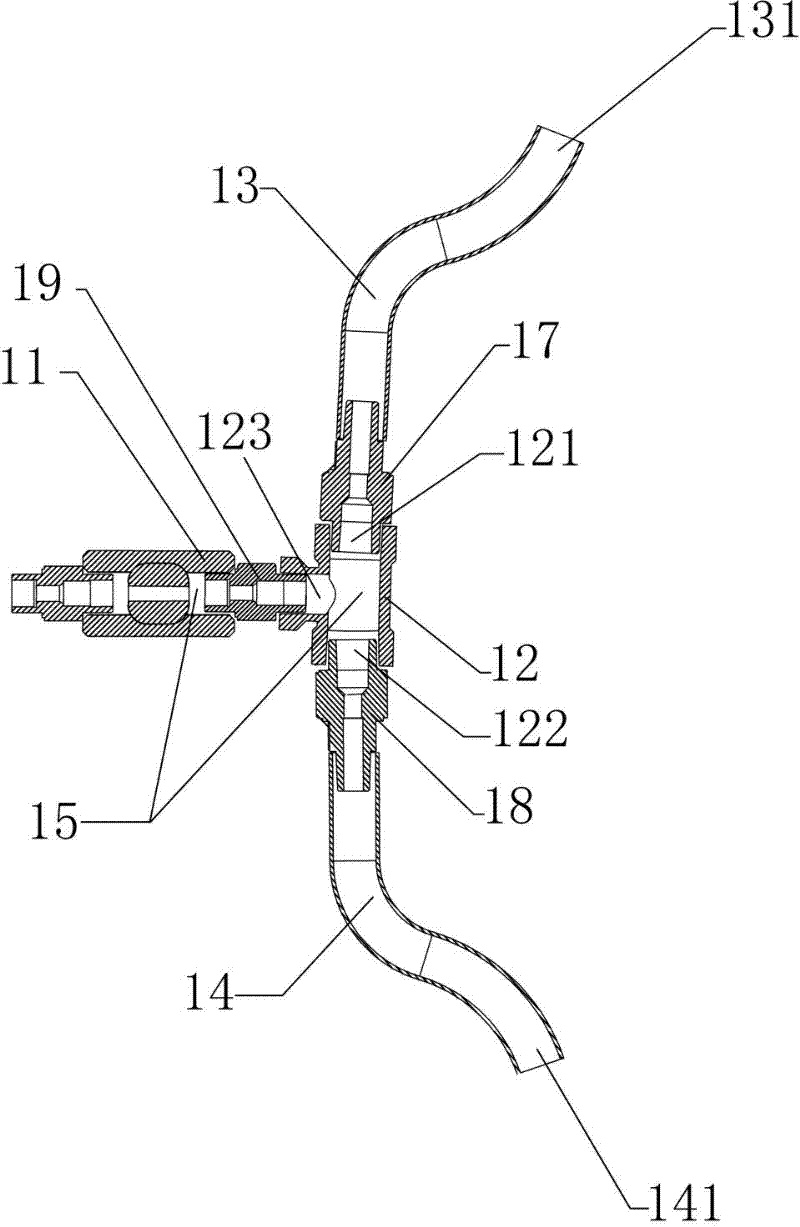

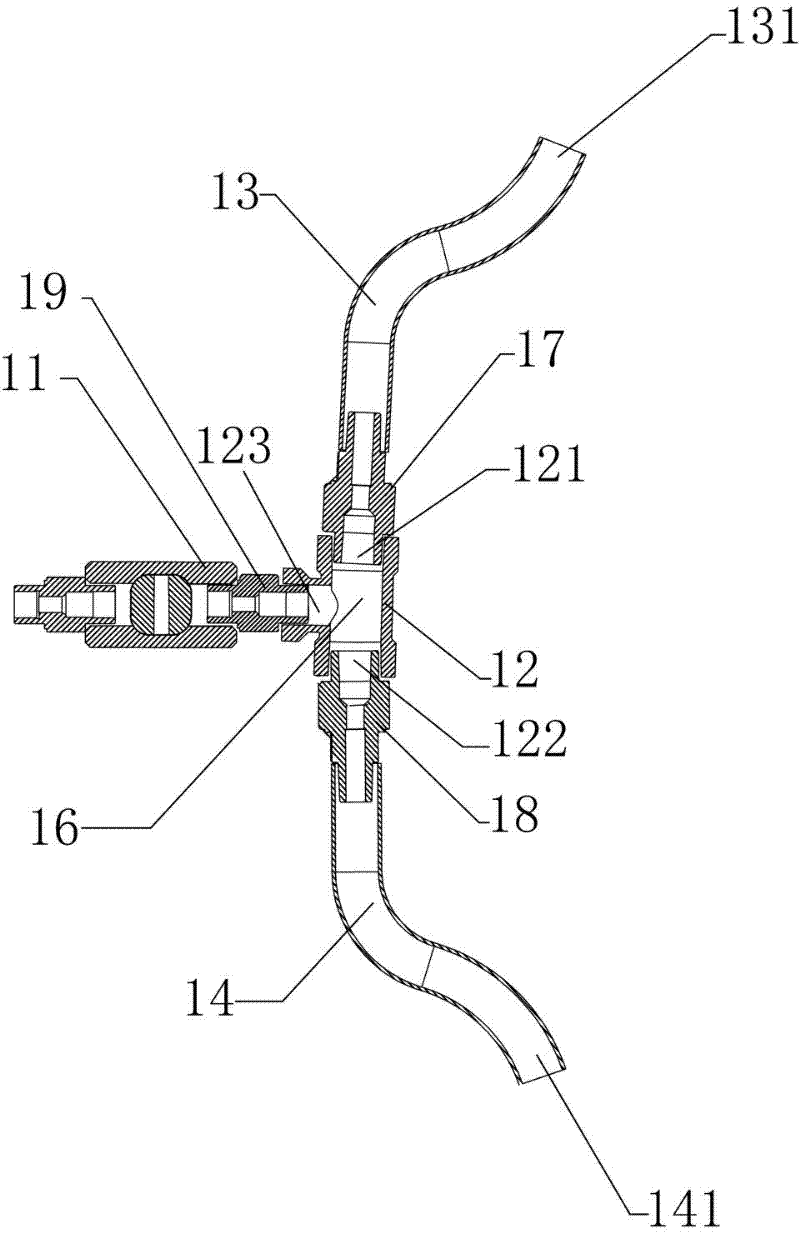

[0025] refer to figure 1 - Figure 7 , a non-energy automatic drainage machine, including a three-way connector 12, the three ports of the three-way connector 12 are respectively connected to the water valve 11, the drainage connecting pipe 13 and the water suction connecting pipe 14, and the other end of the water valve 11 The interface is connected with a water supply device, and the position of the end 141 of the water suction connecting pipe is higher than that of the end 131 of the draining connecting pipe. The water valve 11 is connected with the water supply device, and the water supply device is connected with the three-way connector 12 through the water valve 11, and the three-way connector 12 is connected with the top of the drain connecting pipe 13, the top of the water suction connecting pipe 14 and the water valve 11, and the water suction The end 141 of the connecting pipe is placed in the water at a higher place for absorbing the water at the high place, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com