Once mounting, locating and constructing method for steel ladder outside concrete silo following sliding mould construction

A construction method and concrete technology, which is applied in the direction of construction, building structure, and building material processing, can solve the problems of low construction efficiency and waste, and achieve the effects of saving costs, reducing rental fees, and reducing management fees for management personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

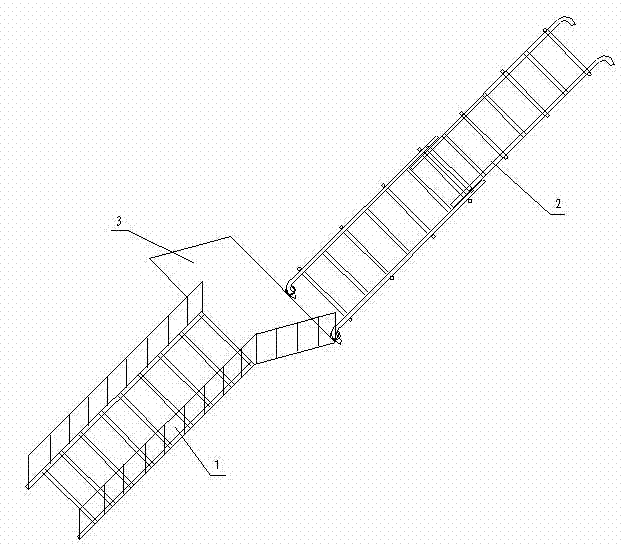

[0015] Such as figure 1 As shown, the outer steel ladder of the concrete silo of the present invention is installed in place with the slipform construction and the construction method comprises the following construction steps:

[0016] a. Leave an upper mouth on the slipform operating platform of the concrete silo, and fix the upper end of the prepared tool-type drawing steel ladder 2 on the slipform enclosure;

[0017] b. Then hook the lower end of the tool-type pull steel ladder 2 to the upper cap 3 of the engineering steel ladder 1;

[0018] c. When the sliding formwork operating platform slides up to the set height during the construction of the concrete silo, (take back the tool-type pull-out steel ladder movable ladder,) weld the engineering steel ladder 1 on the outer wall of the silo;

[0019] d. Repeat steps b to c above until the construction is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com