Adjustment method for steam extraction and heat supply of large steam turbine

A technology of extracting steam for heating and adjusting methods, which is applied in mechanical equipment, engine components, machines/engines, etc., and can solve problems such as inapplicability, inability to meet pressure parameter requirements, and large extraction steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

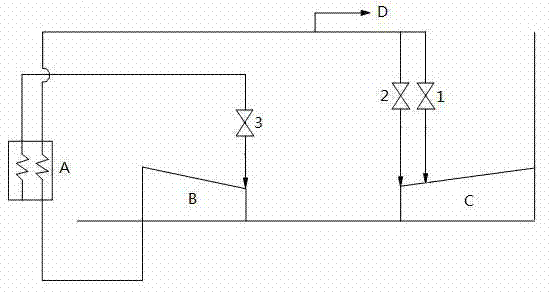

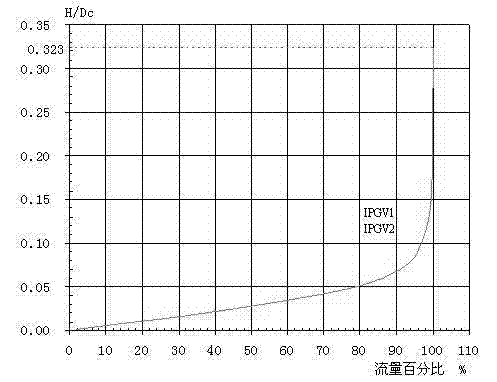

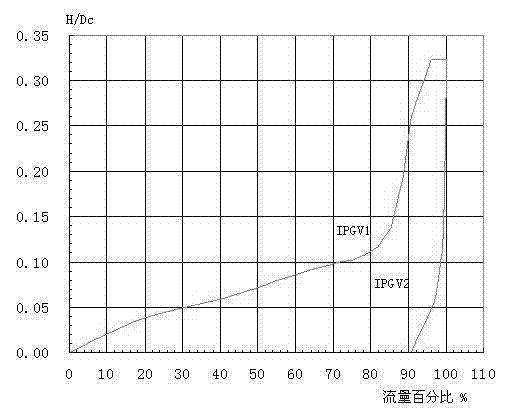

[0018] Such as Figure 1~3 As shown, the heat supply extraction condensing steam turbine is a steam turbine that undertakes two tasks of heat supply and power generation at the same time. According to the structure and operation mode, the heat supply steam turbine can be divided into two categories: back pressure type and regulating extraction type. According to the different nature of heat users, heating steam can be roughly divided into two types: heating extraction steam and industrial extraction steam; steam turbines can be divided into primary, secondary, and tertiary extraction steam turbines according to the number of steam extractions adjusted for heating. The steam extraction or exhaust of the above-mentioned units has a stable working pressure. Therefore, in addition to the speed control system, the steam turbine also has a specially designed pressure regulation system.

[0019] The reheated steam from boiler reheater A reaches the medium-pressure main steam valve an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com