Torsion bar spring combined by multistrand bar steel

A technology of torsion bar springs and strands, applied in the field of torsion bar springs, can solve the problems of high cost, large torque loss, and difficulty in realizing lightweight design, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings of the description.

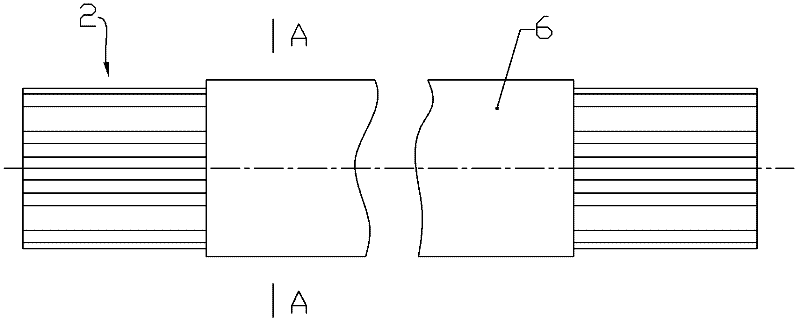

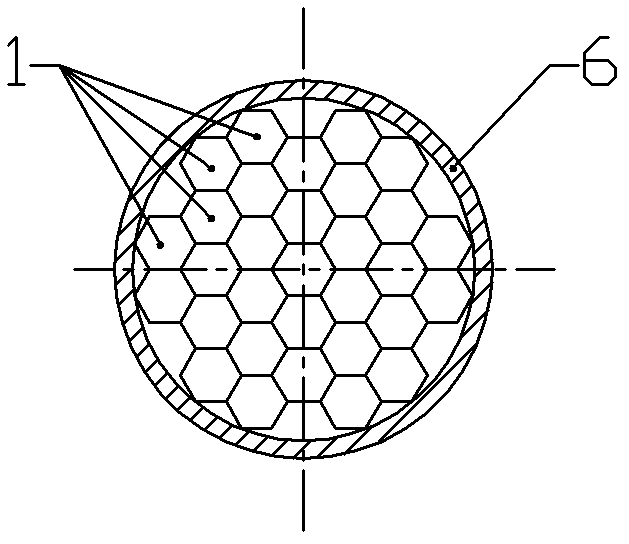

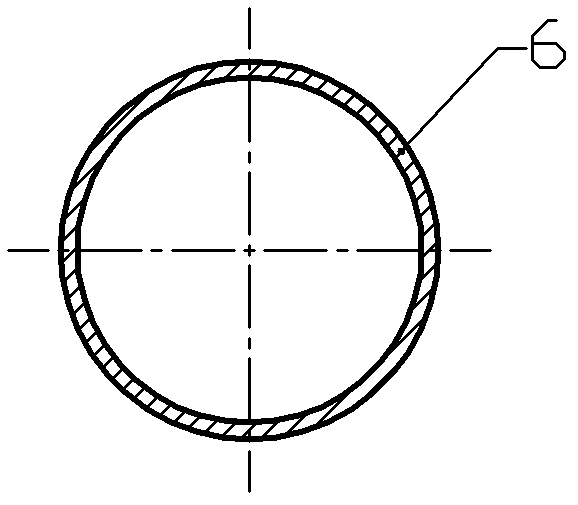

[0023] The torsion bar spring of multi-strand steel combination of the present invention, as figure 1 , 2 As shown, it is a multi-strand assembly 2 composed of at least three strands of steel bars 1 with polygonal cross-sections brought together along the length direction.

[0024] As a further improvement and supplement to the above-mentioned technical solution, the present invention also includes the following additional technical features, although figure 1 , 2 Containing most of the following additional technical features is a preferred embodiment of the present invention, but the present invention is not limited to this situation, and they are selected on the technical solution described in the previous paragraph according to specific effects when implementing the present invention.

[0025] Firstly, the cross section of the bar steel 1 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com