Integrated cooling module for multisystem

A cooling module, multi-system technology, applied in heat exchange equipment, fixed plate duct assemblies, heat exchanger types, etc., can solve the problems of large volume, poor maintainability, and low reliability of cooling devices, and achieve compact structure. The effect of high thermal capacity and reduced life cycle cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

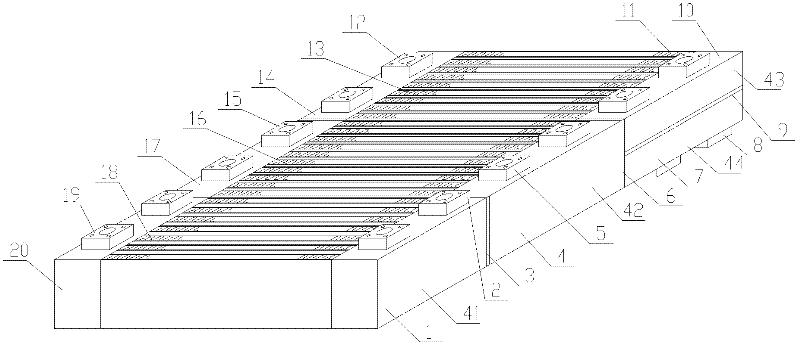

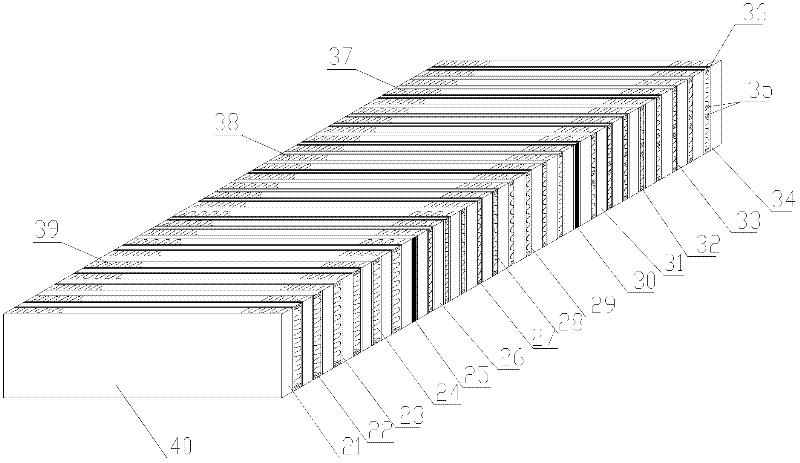

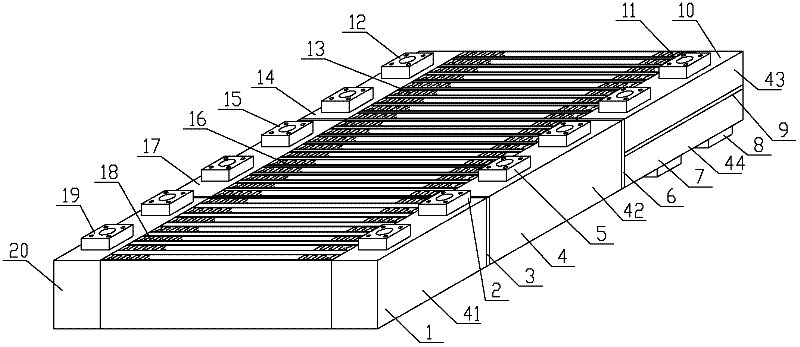

[0018] Now in conjunction with accompanying drawing, the present invention will be further described: please refer to figure 1 , The multi-system overall cooling module includes: air-to-air cooler 41, transmission oil radiator 42, hydraulic oil radiator 43, water radiator 44, etc. The air-to-air cooler 41 is composed of an air inlet chamber 1, an air inlet flange 2, a small core body 18, an air outlet chamber 20 and an air outlet flange 19; the transmission oil radiator 42 is composed of an oil inlet chamber 4, an oil inlet flange 5, Small core body 16, oil outlet chamber 17 and oil outlet flange 15; hydraulic oil radiator 43 is composed of oil inlet chamber 10, oil inlet flange 11, small core body 13, oil outlet chamber 14 and oil outlet flange 12 ; The water radiator 44 is made of water inlet chamber 7, water inlet flange 8, small core body, water outlet chamber and water outlet flange, and the water radiator 44 small core body is below the hydraulic oil radiator 43 small co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com