Separation type microchannel capillary siphon type heat exchanger

A capillary siphon, micro-channel technology, applied in indirect heat exchangers, lighting and heating equipment, cooling/ventilation/heating renovation, etc., can solve the problems of small heat exchange temperature difference, high cabinet height, poor heat dissipation effect, etc. Strong heat exchange capacity, good isothermal effect, and the effect of enhancing environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

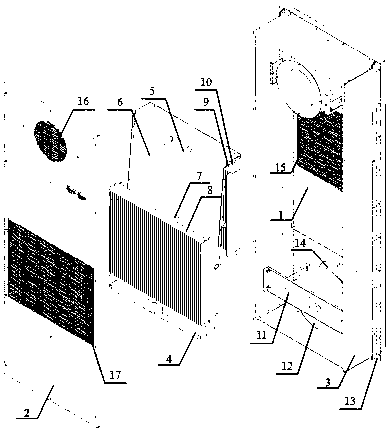

[0034] Further describe in detail below in conjunction with accompanying drawing:

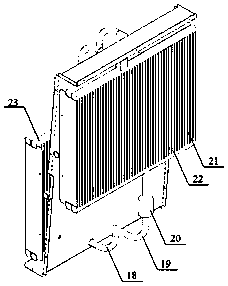

[0035] figure 1 A structural schematic diagram of the present invention is given, a separate micro-channel capillary siphon heat exchanger for heat dissipation in an airtight communication cabinet, including a housing, a separate heat dissipation module and a fan device. The specific structure includes: cold air side panel 1, hot air side panel 2, side panel 3, partition 4, self-circulation ascending pipe 5, pump-driven ascending pipe 6, self-circulation return pipe 18, pump-driven return pipe 19, self-circulation Evaporation heat absorption unit 7, pump driven evaporation heat absorption unit 8, self-circulation condensation heat release unit 9, pump driven condensation heat release unit 10, fan bracket 11, fan 12 and flange 13 are composed of main parts. Have a cold air inlet 14 and a cold air outlet 15 on the cold air side panel 1 , and have a hot air inlet 16 and a hot air outlet 17 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com