Method and device for managing batteries

A technology for batteries and battery packs, applied in battery circuit devices, circuit devices, measuring devices, etc., can solve the problems of low management flexibility, reduced signal accuracy, and complicated wiring, so as to avoid excessively long signal collection lines and improve Signal accuracy, the effect of shortening the signal sampling line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

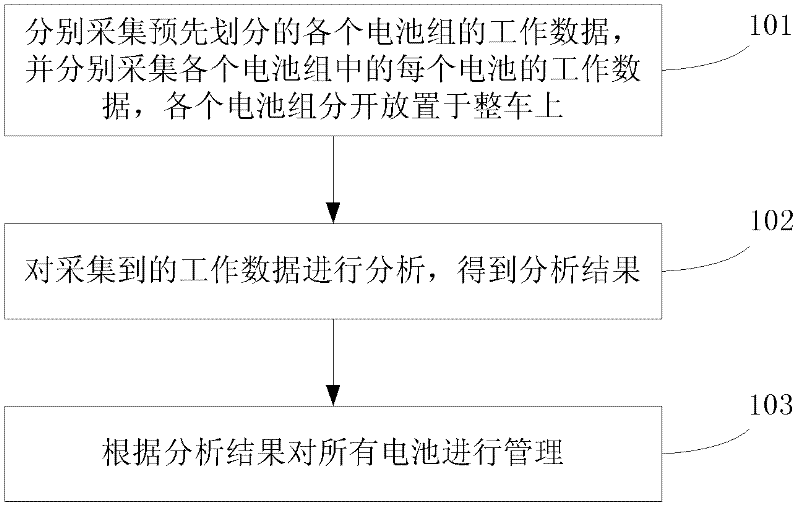

[0047] This embodiment provides a method for battery management, see figure 1 , The method flow is as follows:

[0048] 101: Collect the working data of each pre-divided battery pack, and collect the working data of each battery in each battery pack separately, and each battery pack is open to be placed on the entire vehicle;

[0049] 102: Analyze the collected working data to obtain the analysis result;

[0050] 103: Manage all batteries according to the analysis results.

[0051] Among them, the working data includes at least one of voltage, current and temperature;

[0052] Correspondingly, collect the working data of each pre-divided battery pack, including:

[0053] Collecting at least one of the pre-divided total voltage, total current, and temperature of each battery pack;

[0054] Collect the operating data of each battery in each battery pack, including:

[0055] Collect at least one operating data of voltage, current, and temperature of each battery in each battery pack.

[0056] ...

Embodiment 2

[0064] Example two

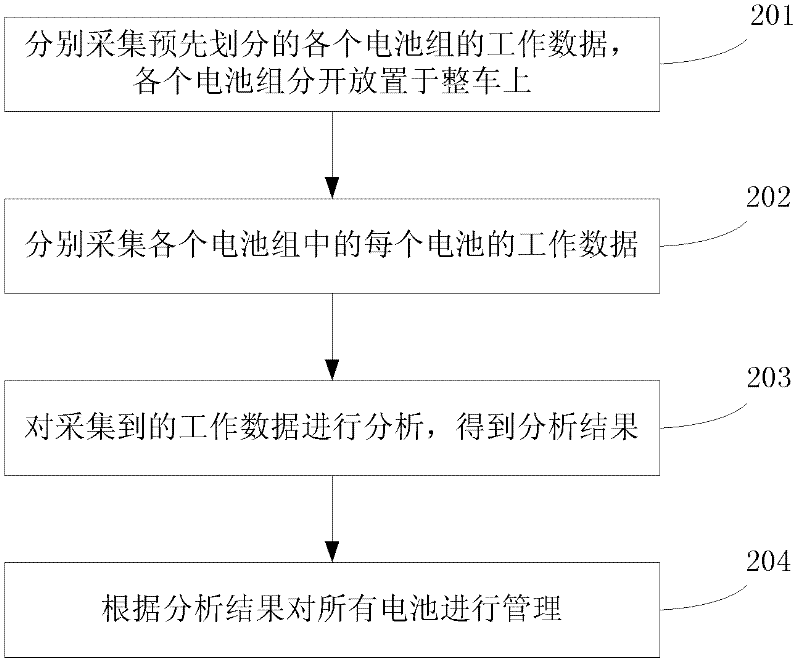

[0065] This embodiment provides a method for battery management, see figure 2 , The method flow is as follows:

[0066] 201: Collect the working data of each pre-divided battery pack, and each battery pack is open to be placed on the entire vehicle;

[0067] For this step, this embodiment does not limit the number of batteries included in each pre-divided battery pack, nor does it limit the division method. For example, for the number of batteries required by an existing car, 12 batteries can be used as one battery. Groups, of course, can also be divided into other ways.

[0068] Similarly, this embodiment does not limit the specific working data, which includes at least one of voltage, current, and temperature.

[0069] Then, when the step of separately collecting the working data of each pre-divided battery pack includes: separately collecting at least one of the working data of the total voltage, total current, and temperature of each pre-divided battery pack. ...

Embodiment 3

[0107] This embodiment provides a device for battery management, see Figure 8 , The device includes:

[0108] The collection module 801 is configured to collect the working data of each pre-divided battery pack, and collect the working data of each battery in each battery pack, and each battery pack is open to be placed on the entire vehicle;

[0109] The analysis module 802 is used to analyze the working data collected by the collection module 801 to obtain the analysis result;

[0110] The management module 803 is configured to manage all batteries according to the analysis result obtained by the analysis module 802.

[0111] Wherein, the working data collected by the collecting module 801 includes at least one of voltage, current and temperature;

[0112] Accordingly, see Picture 9 , Acquisition module 801, including:

[0113] The first collection unit 801a is configured to collect at least one of the pre-divided total voltage, total current, and temperature of each battery pack;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com