Blast furnace operation method

A technology of blast furnace operation and blast furnace, applied in blast furnace, blast furnace details, blast furnace parts, etc., can solve problems such as difficult to avoid poor temperature rise, achieve the effect of inhibiting moisture condensation or zinc compound wall attachment, maintaining stability, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0064] Embodiment 1 is aimed at the operation of a blast furnace in which air or oxygen-enriched air is blown in from the tuyere, that is, the operation of a general blast furnace. When the oxygen-enriched air is blown through the tuyere, it is usually operated at an oxygen enrichment rate of 20% by volume or less, preferably 10% by volume or less. It should be noted that as the oxygen enrichment rate increases, the amount of gas passing through the furnace decreases, and the amount of blown gas required to raise the temperature of the upper part of the furnace body increases significantly. operate.

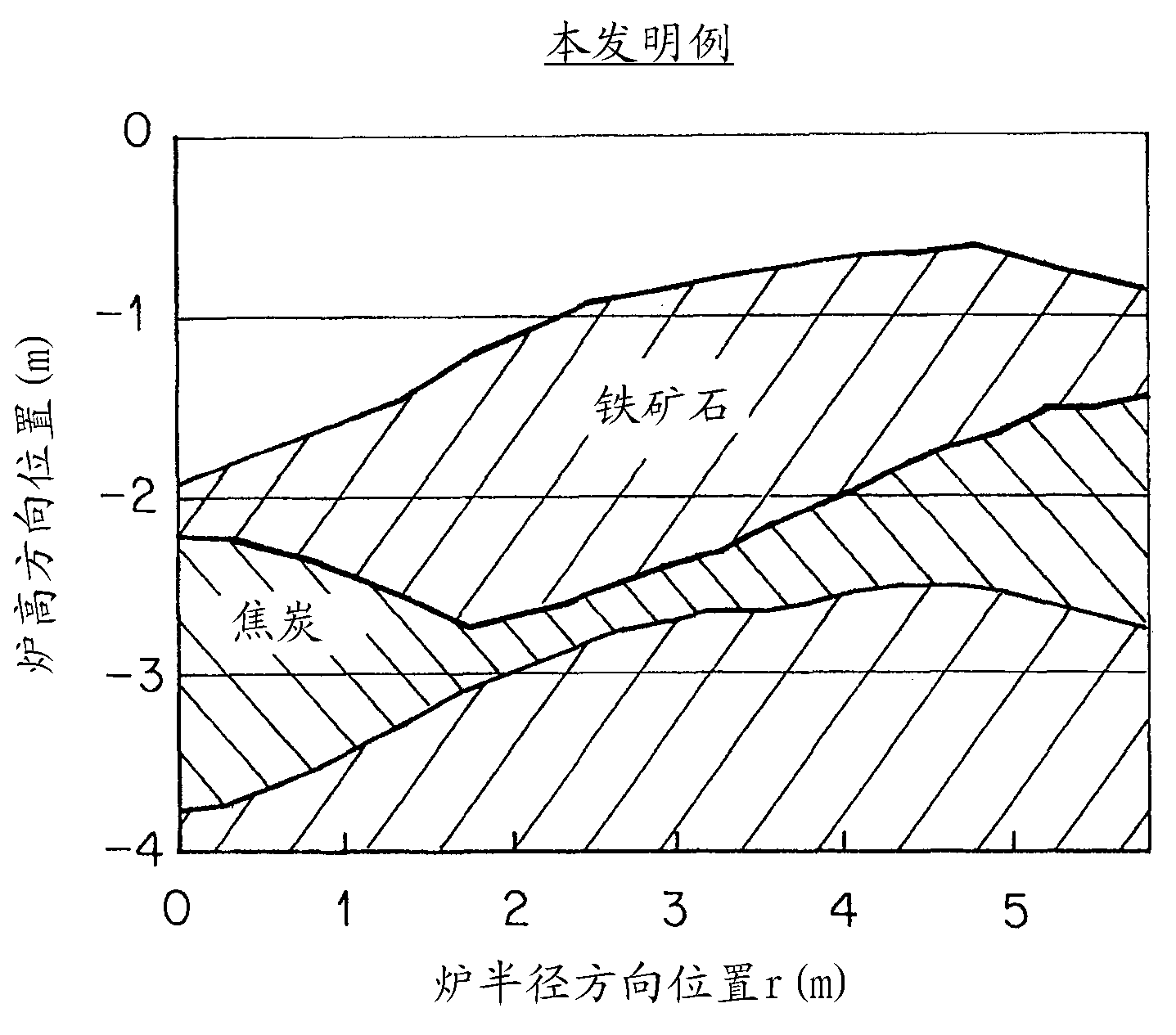

[0065] In Embodiment 1, air is blown into the furnace in order to raise the temperature of the upper part of the furnace, but if figure 1 As shown in the model, when the radius of the furnace mouth is R 0 , the depth from the material line is R 0 The position is p 1 , the height from the lower end of the furnace body is 1 / 3 of the total height of the furnace body, and p is 2...

Embodiment approach 3

[0121] The inventors reproduced using Figure 18 In the shown experimental facility 10 for blowing the preheating gas into the blast furnace, an experiment was carried out in which the preheating gas was blown with the oxygen concentration actually set to zero. should be explained, Figure 18 Among them, 11 is the raw material (sintered ore), 12 is the heater, and 13 is the burner.

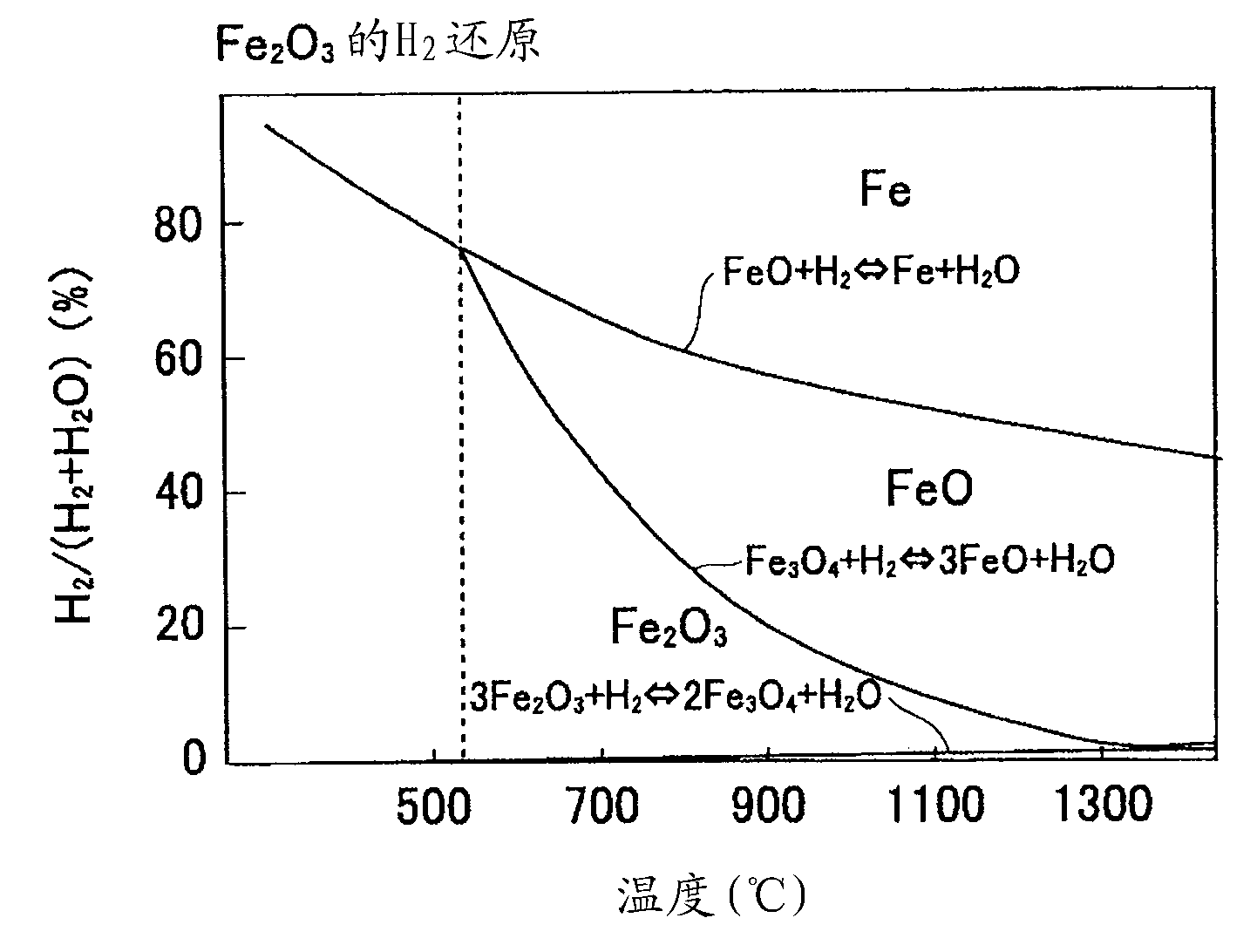

[0122] First, before starting the blowing of the preheating gas in this experimental device, the CO: 30%, CO 2 : 20%, N 2 : 50% mixed gas is heated to 500°C and blown in from the bottom, when collecting sinter in the furnace, there is almost no Fe 2 o 3 , and by Fe 3 o 4 occupy. Afterwards, the blast furnace gas is completely combusted, and the oxygen-free preheated gas is heated to 800°C by the burner 13 and blown in. When the sintered ore around and above the blown position is collected, it basically turns back to Fe 2 o 3 . This is caused by Figure 19 The equilibrium state diagram o...

Embodiment 1

[0144] In order to confirm the effect of Embodiment 3, use the Figure 18 The experimental setup shown blows preheated gas into the shaft section.

[0145] At this time, as an example of the present invention, preheating gas is blown into the shaft part based on Embodiment 3 to 2 of the present invention described above. That is, the oxygen concentration of the blown preheating gas is 0, and then as Figure 23 As shown, the CO concentration is expressed as CO / (CO+CO 2 ) are calculated as 6% and 12%, and the temperature is 800°C.

[0146] On the other hand, as a conventional example, preheating gas is blown into the shaft part based on the said patent document 1. That is, the oxygen concentration of the blown preheating gas is 0, and then as Figure 23 As shown, the CO concentration is expressed as CO / (CO+CO 2 ) is calculated as 0%, and the temperature is 800°C.

[0147] As a result, in the conventional example, as in the previous experiment (column [Problem to be Solved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com