Blast furnace operation method, low-calorific-value gas combustion method for same, and blast furnace equipment

A technology of blast furnace operation and combustion method, applied in the field of blast furnace operation and combustion of low calorific gas used for it, and blast furnace equipment, capable of solving problems such as soot generation, increased generation of harmful substances, and environmental pollution sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

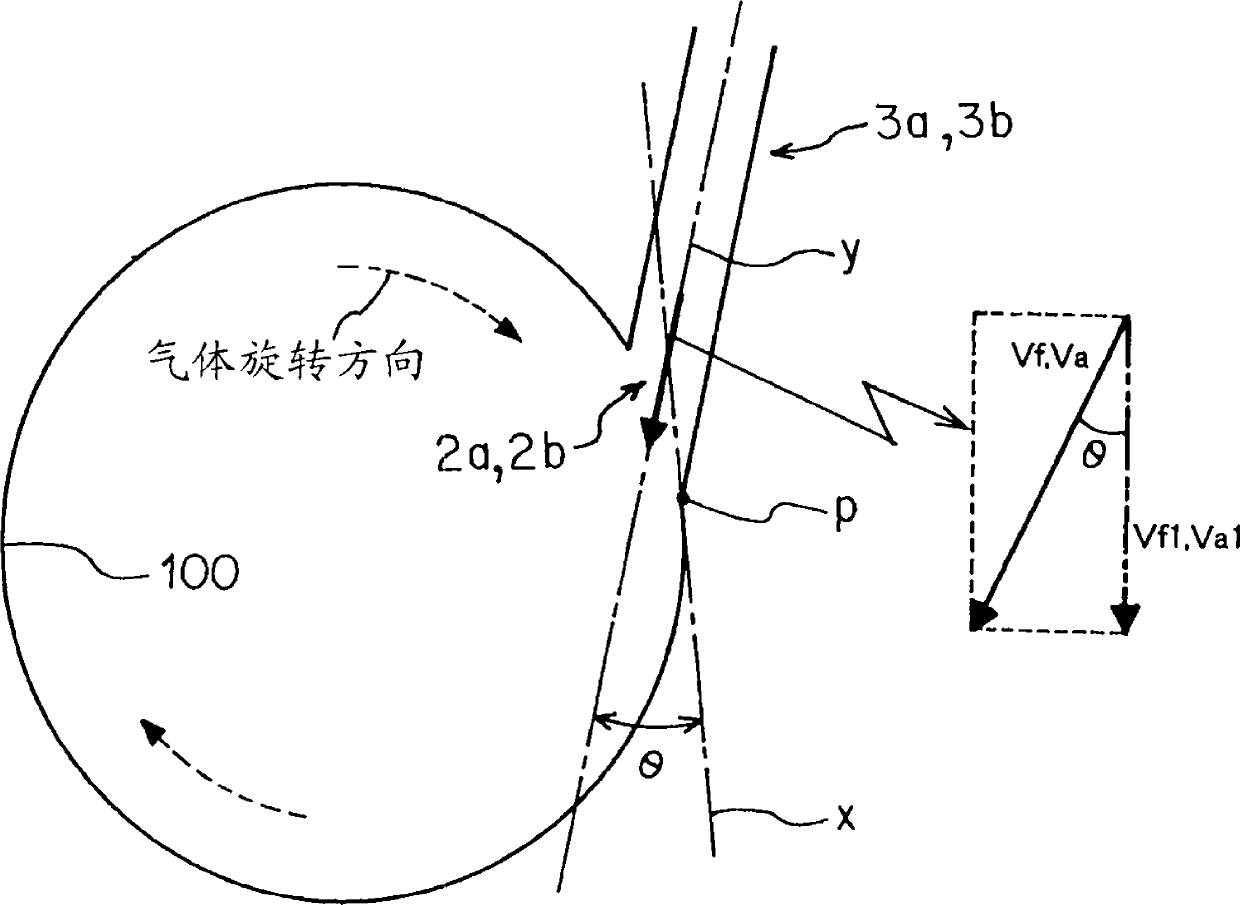

[0214] In order to verify the function of the gas combustion used in the present invention? Injection device a, use Figure 8 In the test device (corresponding to gas combustion and injection device a) with the structure shown above, a combustion test was carried out in which the supply pressure of fuel gas (low calorific value gas) and combustion-supporting gas (air) was increased. The combustion chamber of this test device has an inner diameter: 50mm, a total length: 300mm, and the length of the opening (nozzle slit) for injecting fuel gas formed on the inner wall surface: 48mm, width: 5mm, similarly, the combustion-supporting gas is injected into The length of the opening (nozzle slit) used: 31mm, width: 5mm.

[0215] The gas composition of low calorific gas used as fuel gas is CO: 22vol%, CO 2 : 21vol%, H 2 : 5vol%, N 2 : 52vol%, calorific value is 792kcal / Nm 3 . Relative to the fuel gas 30Nm 3 / h, supply air 19.5Nm 3 / h so that the theoretical oxygen content is 1. ...

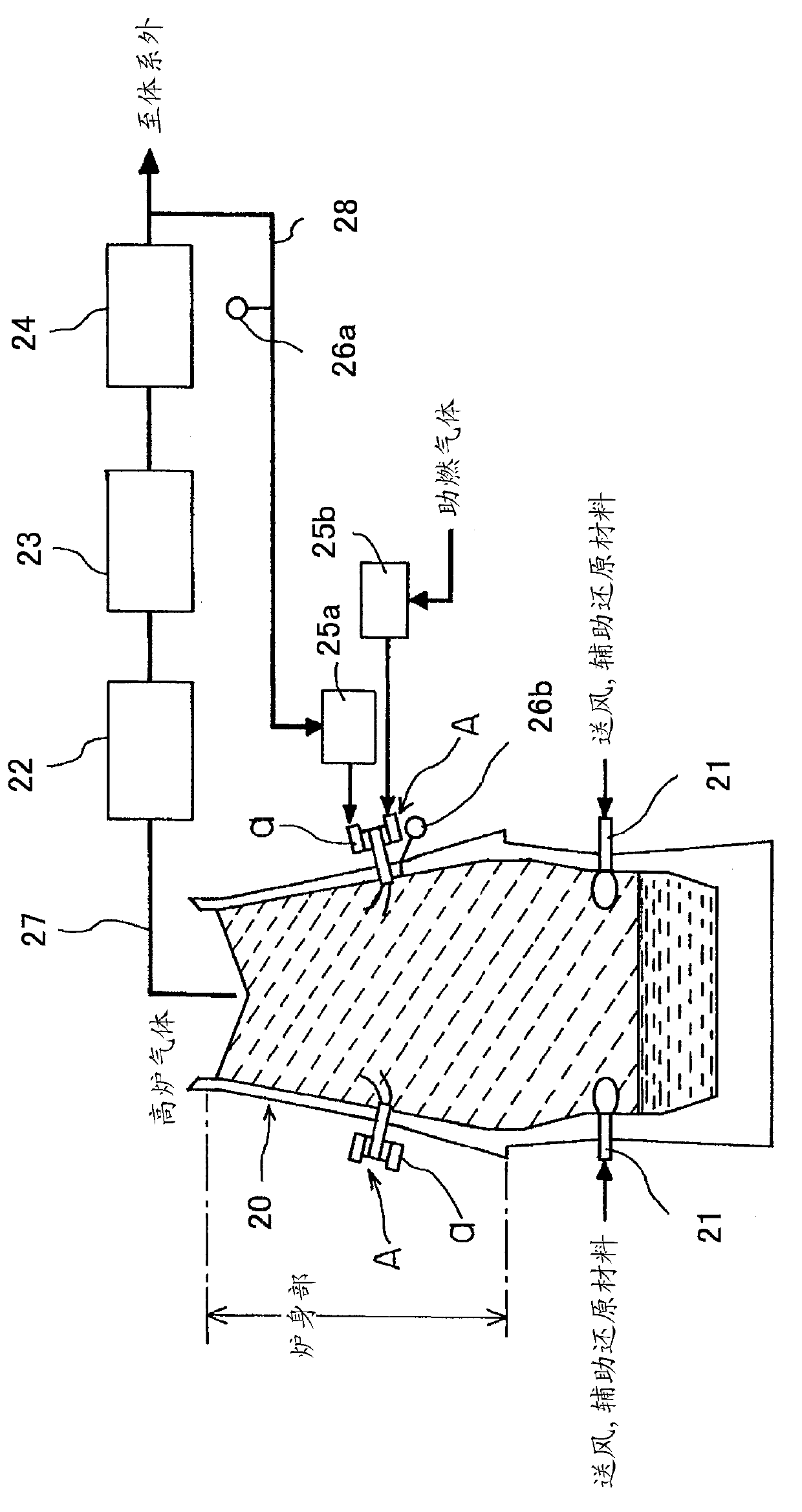

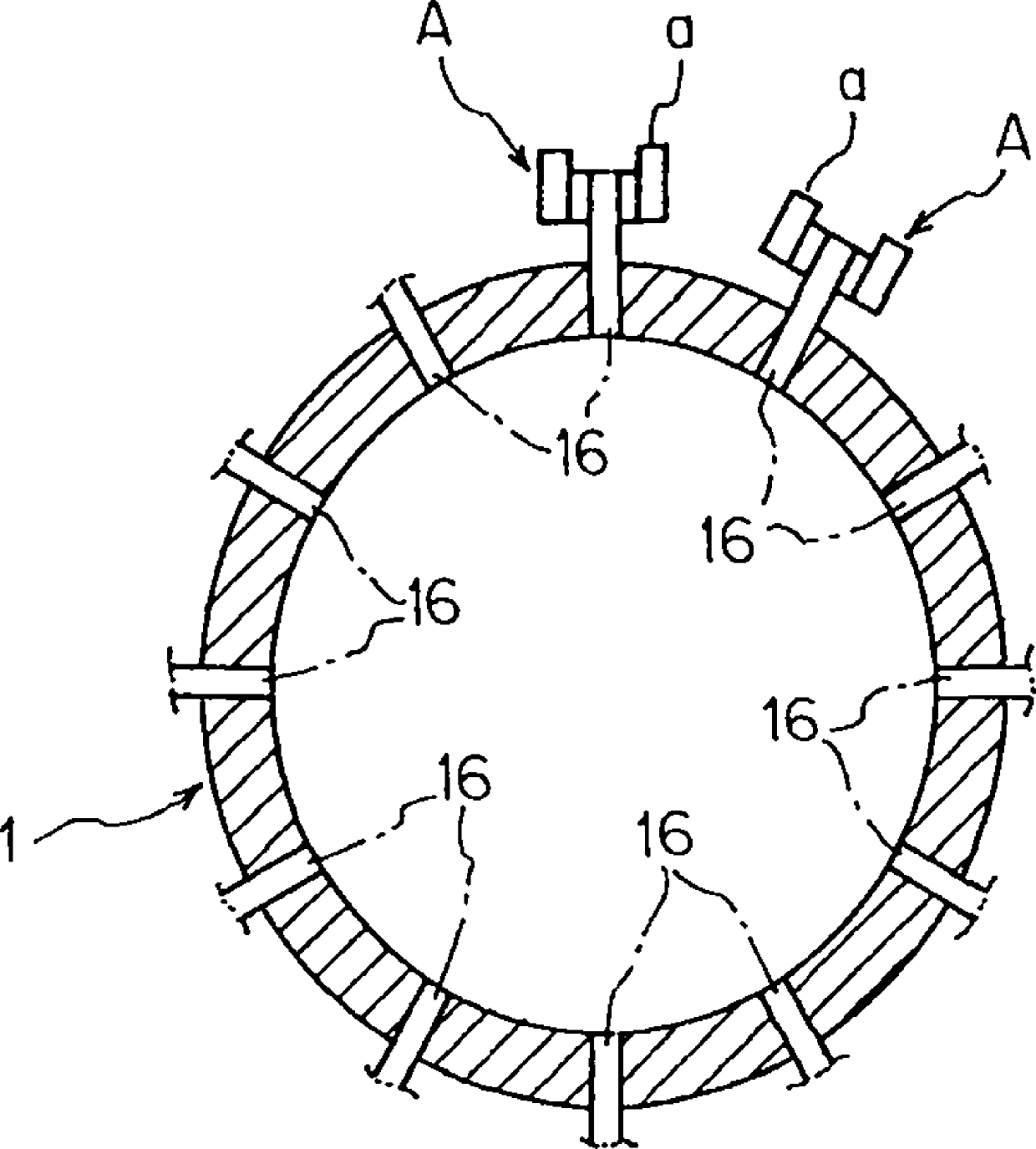

Embodiment 1

[0234] Furnace volume 5000m 3 In the blast furnace, use such as figure 2 and image 3 The gas shown is combusted? Blown into device a, as in figure 1 The illustrated embodiments are used to practice the invention. The blast furnace gas taken out from the downstream side of the furnace top gas power generation unit 24 is boosted to a pressure 0.2 atm higher than the furnace internal pressure with a booster 25a, and introduced as fuel gas into the gas combustion / injection device constituting the gas injection unit A. a. In addition, similarly, oxygen is boosted by the booster 25b, and introduced into the gas combustion / injection device a as a combustion-supporting gas. Set the blast furnace gas supply rate to 100Nm for gas combustion? Injection device a 3 / t, making it oxygen 5.6Nm 3 / t is burned to generate 800°C combustion gas, which is blown into the furnace as preheating gas. Gas combustion? The oxygen ratio blown into device a is 0.335 (relative to the theoretical ox...

Embodiment 2

[0236] Furnace volume 5000m 3 In the blast furnace, use such as Figure 4~Figure 7 The gas shown is combusted? Blown into device a, as in figure 1 The illustrated embodiments are used to practice the invention. The blast furnace gas taken out from the downstream side of the furnace top gas power generation unit 5 is boosted to a pressure 0.2 atm higher than the furnace internal pressure with a booster 25a, and introduced as fuel gas into the gas combustion / injection device constituting the gas injection unit A. a. In addition, similarly, oxygen is boosted by the booster 25b, and introduced into the gas combustion / injection device a as a combustion-supporting gas. Gas combustion? Blow into device a to make blast furnace gas 30.3Nm 3 / t with air 5.6Nm 3 / t (oxygen ratio 1.0) for combustion, while supplying dilution gas (BFG) 69.7Nm into the combustion chamber 3 / t, thereby generating combustion gas at 800°C and blowing it into the furnace as preheating gas. The compositio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com