Filter material for ultrafine dust filtering and preparation method thereof

A technology for dust filtration and filter material, applied in the field of industrial filter material and its preparation, can solve the problems of unsatisfactory application effect and cost performance of bag filter, large resistance of film-coated filter material, uneven air permeability, etc. Warp and weft strength and elongation at break index, low filtration resistance, and the effect of improving air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

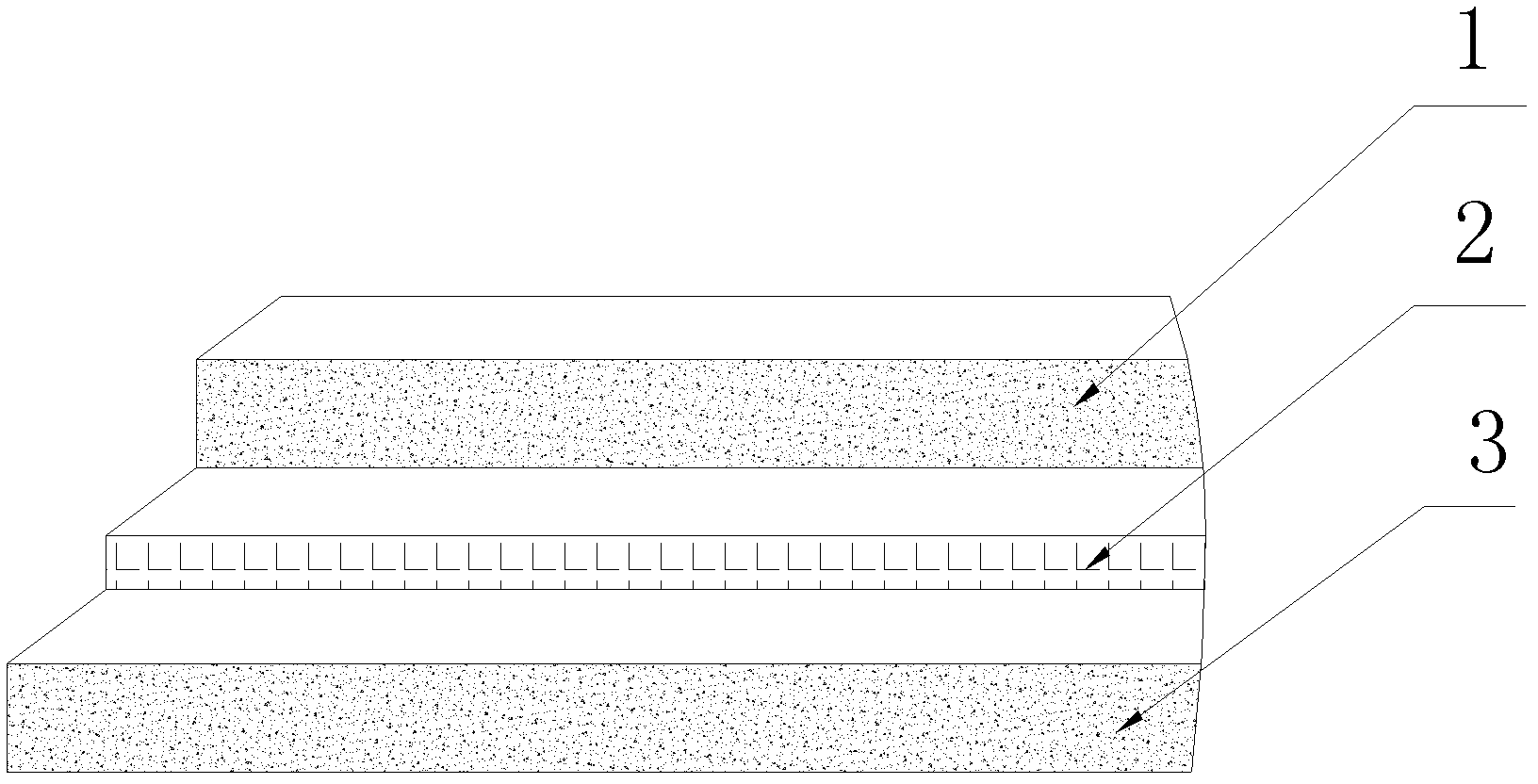

[0020] Such as figure 1 The shown filter material for filtering ultrafine dust consists of three layers, including an upper layer of ultrafine denier fiber (0.05-0.08 denier), a middle layer of woven mesh cloth and a lower layer of coarse denier fiber (2.65 denier). denier), the content of the superfine denier fiber layer, the woven mesh layer and the coarse denier fiber layer is (parts by weight): 185~220:80~110:185~220. The content of superfine denier fiber, woven mesh cloth and coarse denier fiber is preferably (parts by weight): 200:100:200. The warp strength of the woven mesh is ≥1600N (50mm×200mm), the weft strength is ≥1500N (50mm×200mm), and the mass per unit area of the woven mesh is 80~110g / m 2 .

[0021] The above-mentioned filter material preparation method for superfine dust filtration comprises the steps:

[0022] ① The unopened fine denier fibers are opened, homogenized, mixed, and combed into the upper fine denier fiber web layer;

[0023] ②The coarse den...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com