Totally closed gas atomization pulverization device

A technology of gas atomization and powder making device, which is applied in the field of gas atomization melt to manufacture ultrafine powder, can solve the problems of metal blockage, oxide and nitride blockage of the guide tube, etc. or damaged, flush-end effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

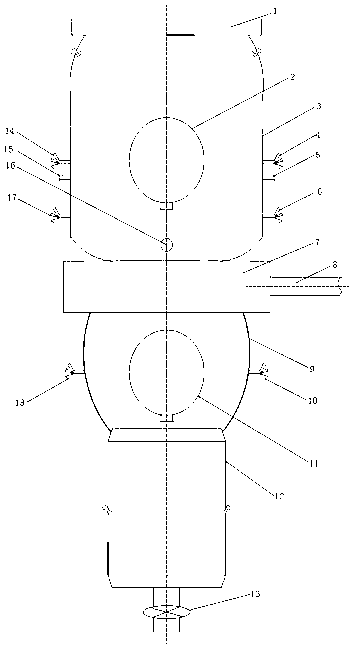

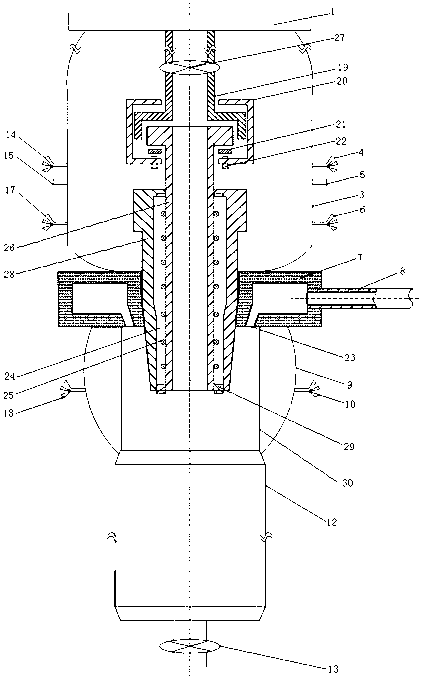

[0056] A fully enclosed gas atomization powder making device, the schematic diagram of its appearance and structure is as follows: figure 1 As shown, in the figure, 1 is a thermal insulation crucible, 2 is an extraction port A, 3 is a telescopic plastic tube A, 4 is a glove I, 5 is a power supply interface I connected to the heating body of the nebulizer, 6 is a glove II, and 7 is a The nozzle of the atomizer, 8 is the intake pipe of the nozzle, 9 is the retractable plastic tube B, 10 is the glove III, 11 is the extraction port B, 12 is the atomization tower, 13 is the valve of the atomization tower, 14 is the glove III 15 is the power supply interface II for the heating body of the atomizer, 16 is the vacuum pump interface, 17 is the glove V, and 18 is the glove VI.

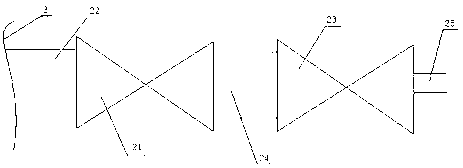

[0057] There is a two-layer vacuum valve on the above-mentioned extraction port A2, and the structural diagram is as follows: figure 2 As shown, among the figure, 21 is an inner layer vacuum valve, 22 is an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com