Static pressure air suspension direct drive turntable

A technology of direct drive and turntable, applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems that affect the dynamic performance and positioning accuracy of the turntable, reduce the dynamic performance of the turntable, generate oil, particles, etc., to achieve high Effects of dynamic and static performance and precision, improved stability, high dynamic performance and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

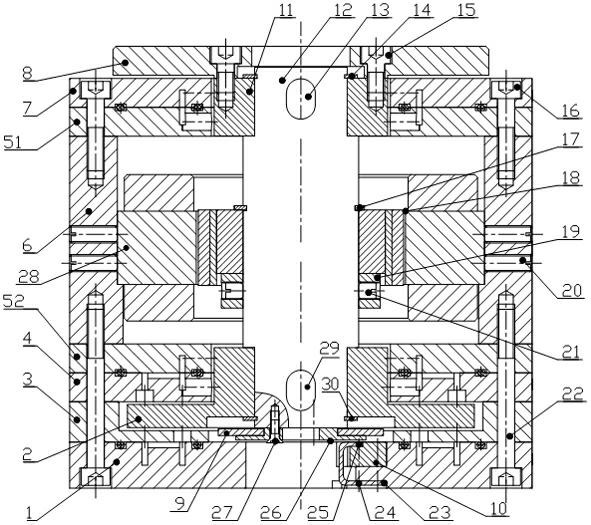

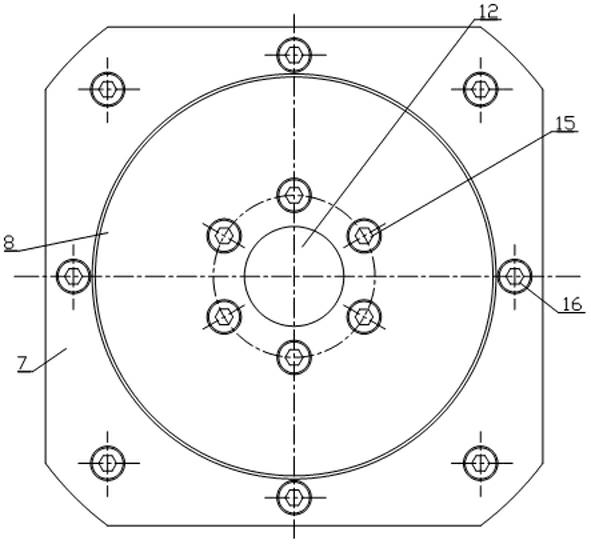

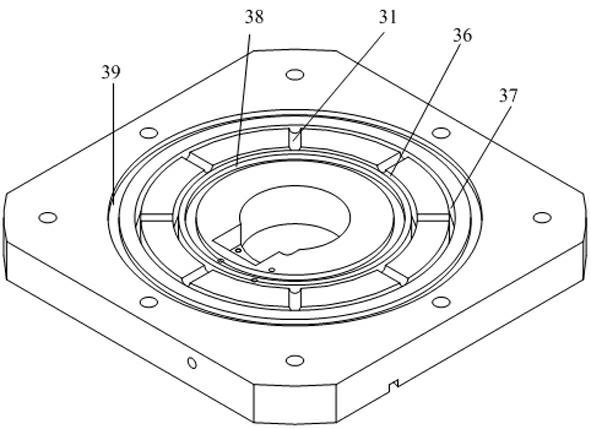

[0024] Such as Figures 1 to 6As shown, the static pressure air bearing direct drive turntable includes a base 1, a base connecting block 3, a rotating shaft 12, a torque motor rotor 18, a torque motor stator 28 and a torque motor mounting frame 6; a torque motor is fixedly installed on the rotating shaft 12 The rotor 18, the torque motor stator 28 is connected with the torque motor mounting frame 6; the upper air bearing ring 11 is installed on the top of the rotating shaft 12, and the upper air bearing ring 11 corresponding to the upper air bearing ring 11 is arranged above the torque motor mounting frame 6 An air bearing assembly, the first air bearing assembly is a rotating air bearing assembly supporting the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com