Chip removing device used in lathe

A technology of lathes and debris, applied in the field of lathes, can solve problems such as incomplete elimination of debris, difficulty in debris cleaning, and environmental pollution, and achieve the effects of easy implementation, environmental protection, and health protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

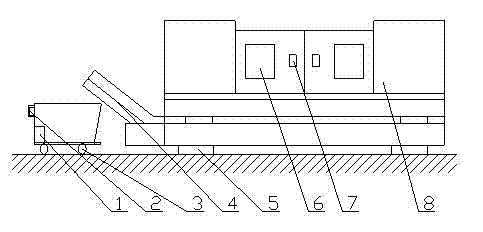

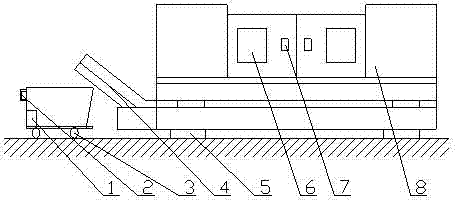

[0009] The debris removal device used on lathes is composed of handrail 1, chip discharge port 2, chip removal vehicle 3, transmission mechanism 4, lathe base 5, observation window 6, handle 7, protective door 8, and protective system 9 The protective system 9 on the vehicle body has two protective doors 8, and each protective door 8 has an observation window 6 and a handle 7. The protective system 9 has a transmission mechanism 4 inside, and this transmission mechanism 4 can communicate with the outside. The mechanism 4 communicates with the outside to directly above the chip removal vehicle 3 , the chip removal vehicle 3 has a handrail 1 and a chip discharge port 2 , and the bottom of the protection system 9 is a lathe base 5 .

[0010] The advantages of the present invention are: the chip removal vehicle 3 can transport debris and waste materials separately, and has a chip discharge port, which is convenient for dumping. The protection system 9 has an observation window, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com