Bearing centering device

A centering device and bearing technology, applied in the field of mechanical spare parts, can solve the problems of increased rejection rate of processed products, poor appearance quality of the bearing inner ring, no automatic centering function, etc., so as to improve the appearance quality and the inner diameter dimensional accuracy. and roundness, the effect of good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

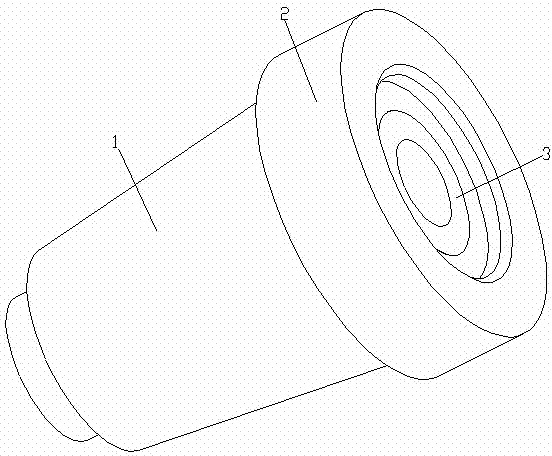

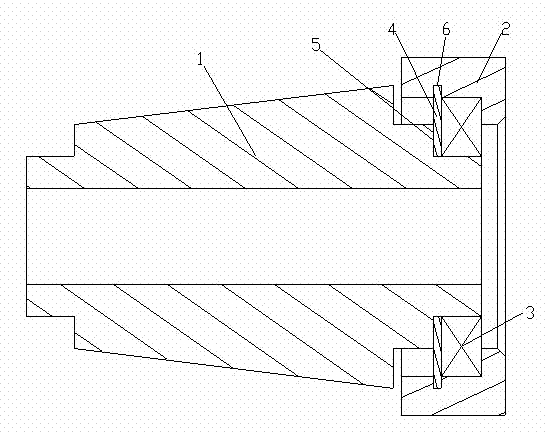

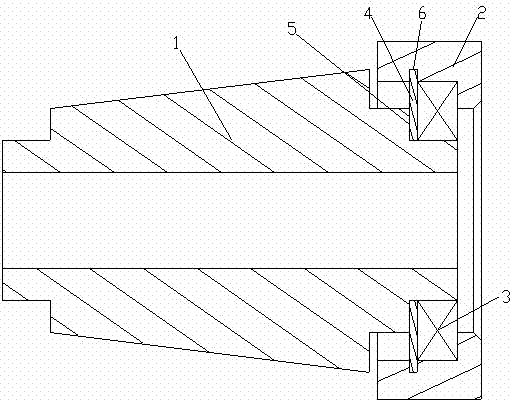

[0013] attached figure 1 , 2 It is a bearing centering device according to the present invention, which includes a centering shaft 1 and a centering sleeve 2; the centering shaft 1 includes a first shoulder 5; the centering sleeve 2 is equipped with a bearing 3, a spring stop ring 4; the spring retaining ring 4 is stuck in the groove 6 of the centering sleeve 2 to restrain the axial movement of the bearing 3; the centering sleeve 2 is arranged on the first centering shaft 1 through the bearing 3 On the shaft shoulder 5; the centering sleeve 2 and the bearing 3 are interference fit, which can realize the functions of bearing radial force and rotating.

[0014] Due to the application of the above-mentioned technical solution, the present invention has the following advantages compared with the prior art:

[0015] The bearing centeri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com