Unloading trolley with material separation device

A technology of unloading trolley and distributing device, which is applied in the direction of transportation and packaging, conveyor objects, etc., and can solve the problem that the damage rate of the three-way distributor flap is increased, the damage rate cannot be effectively improved, and the equipment parts are not easy to disassemble and replace. and other problems, to achieve good dust removal and environmental protection effects, flexible unloading methods, and save equipment installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

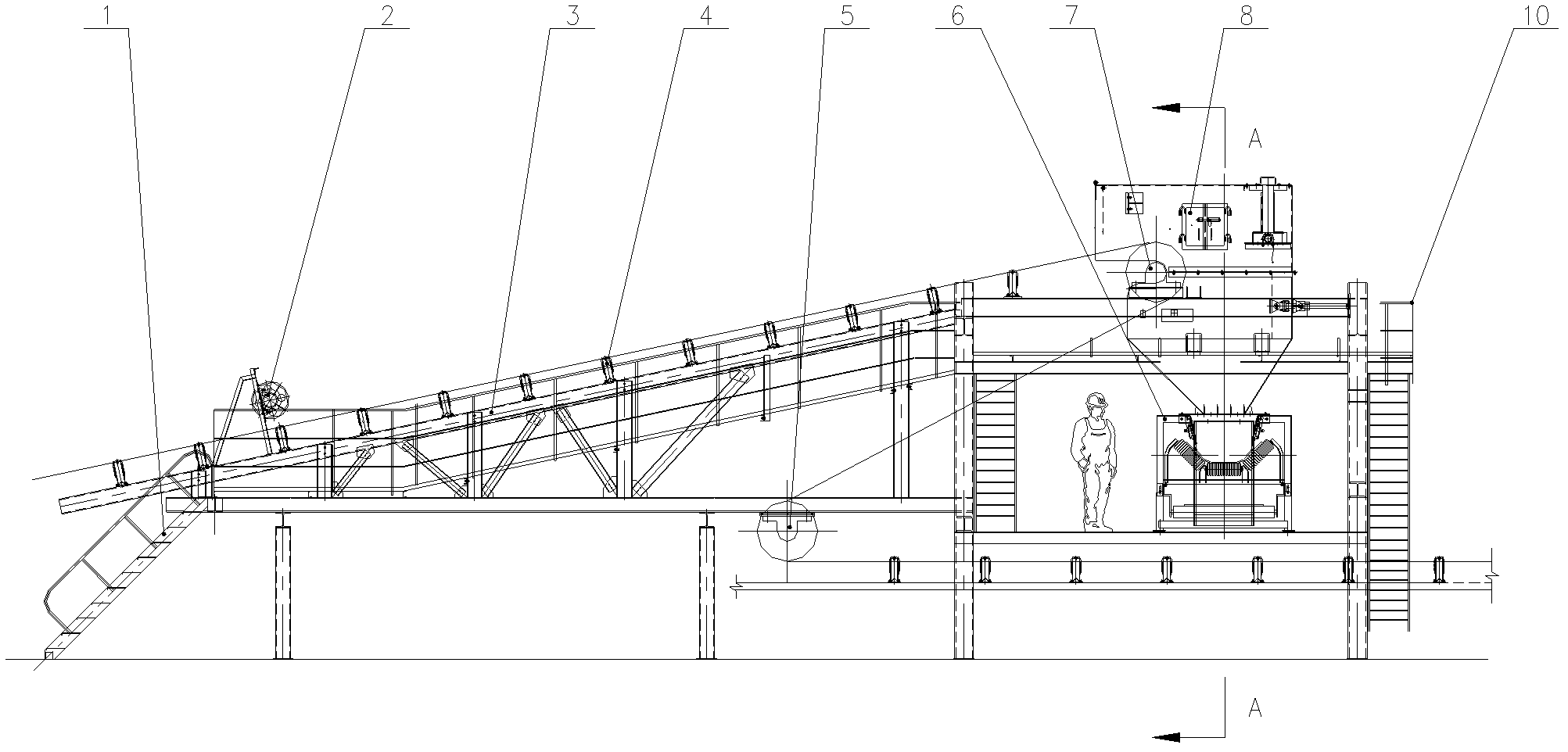

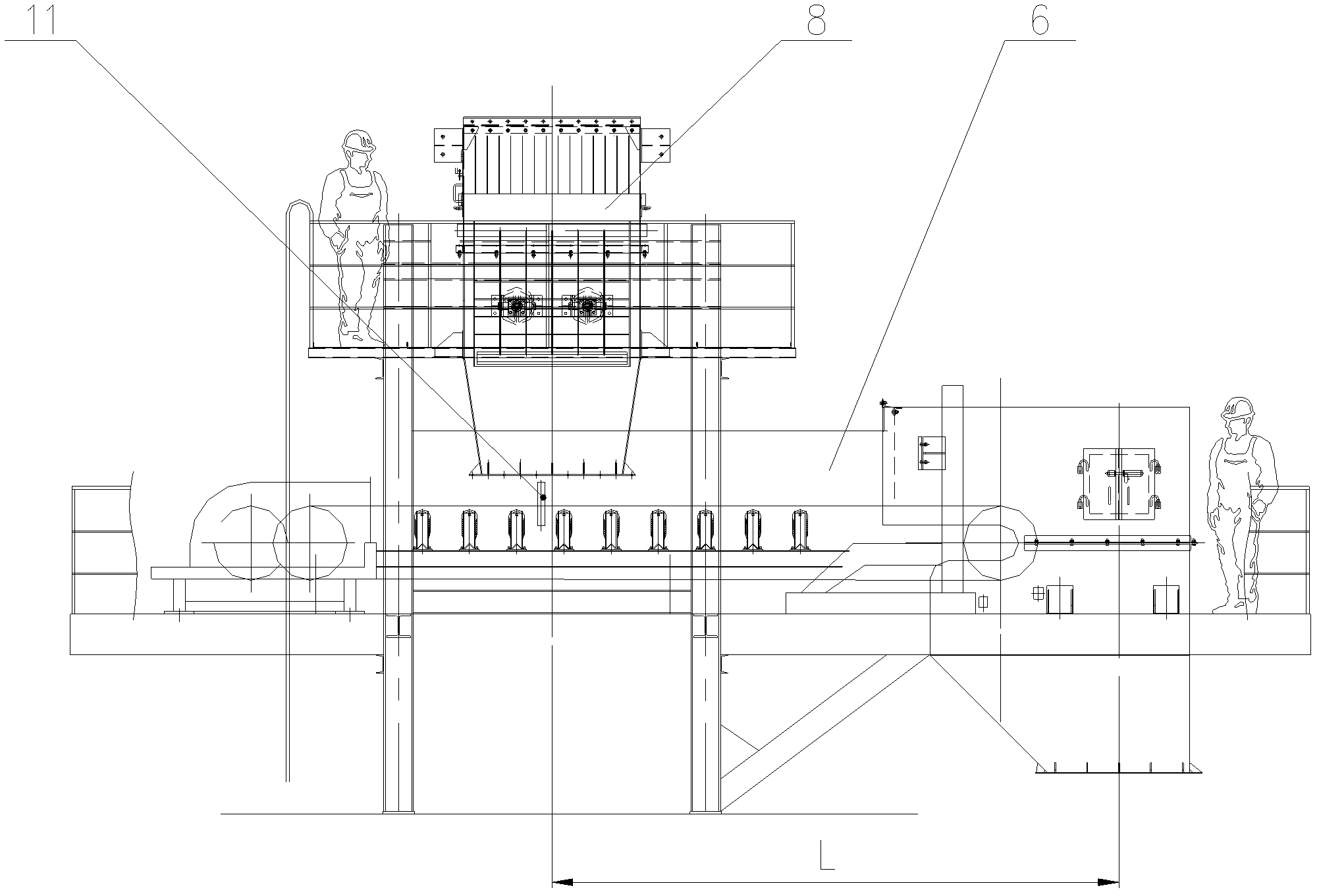

[0036] see figure 1 , 2, The unloading trolley with a material distribution device shown in 5, including a ladder 1, a pressure pulley 2, a frame 3, a trough roller group 4, a reversing roller 5, a belt conveyor 6, and a head unloading roller 7. Funnel 8, maintenance platform 10, anti-belt deviation device 11, centralized lubrication device, funnel shield 13; funnel shield 13 is located above the funnel 8 and surrounds the funnel 8 from around the funnel 8, and the upper periphery of the funnel 8 is provided with a maintenance platform 10. It is characterized in that: a belt conveyor 6 is arranged along the front and back directions under the outlet of the funnel 8, and the horizontal distance between the unloading point of the belt conveyor 6 and the outlet of the funnel 8 can be adjusted without increasing the overall height of the conveyor equipment; The deviation device 11 is located below the outlet of the funnel 8 corresponding to the center of the outlet of the funnel ...

Embodiment 2

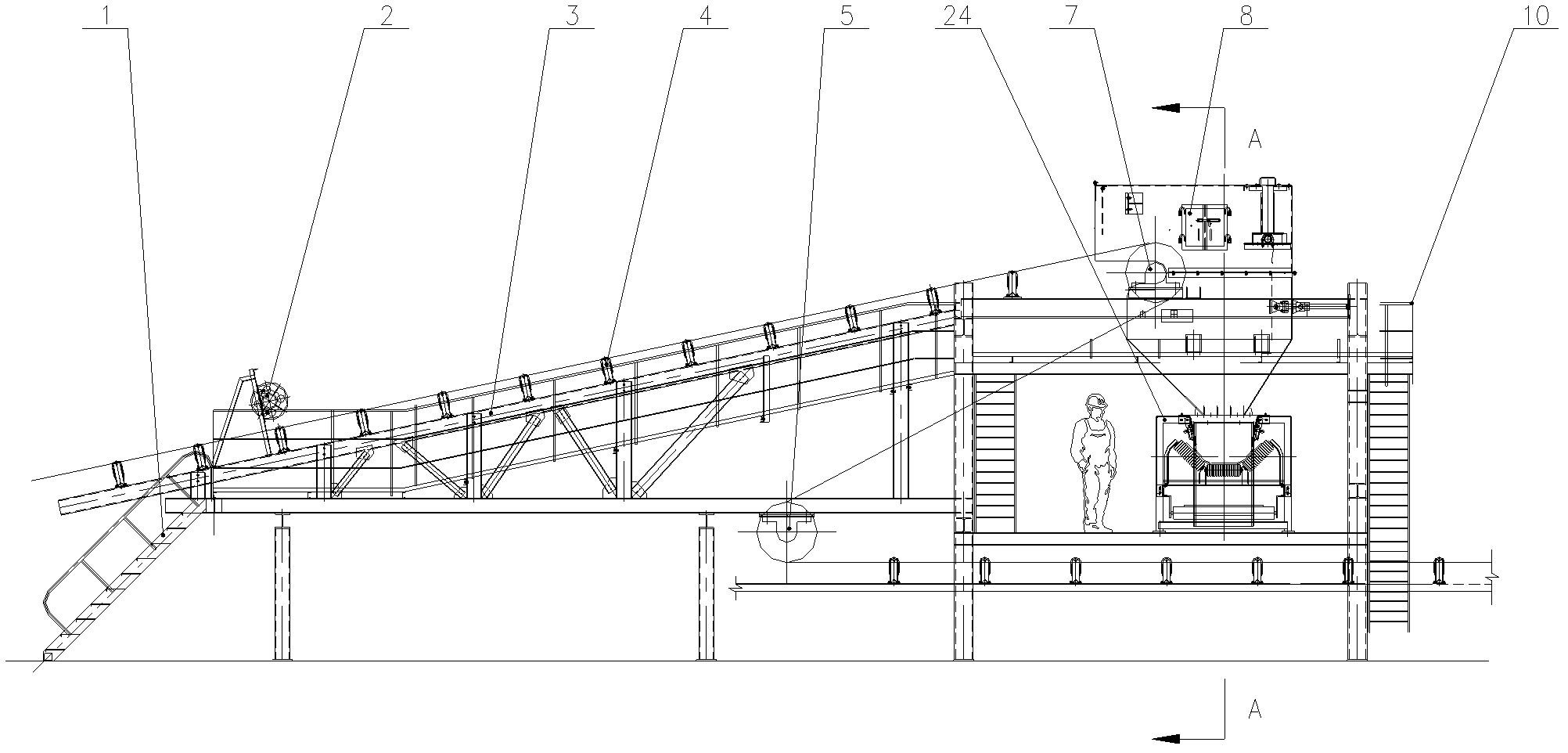

[0045] see image 3 , 4 , The unloading trolley with material distributing device shown in 5, including climbing ladder 1, pressure belt wheel 2, vehicle frame 3, trough roller group 4, reversing roller 5, reversible belt conveyor 24, head unloading Roller 7, funnel 8, maintenance platform 10, anti-belt deviation device 11, centralized lubrication device, funnel shield 13; funnel shield 13 is located above the funnel 8 and surrounds the funnel 8 from around the funnel 8, and the upper periphery of the funnel 8 is set for maintenance Platform 10; a reversible belt conveyor 24 is arranged along the front and rear directions below the outlet of the funnel 8, and the discharge points at both ends of the reversible belt conveyor are symmetrically or asymmetrically located on the front and rear sides of the outlet of the funnel, and between the discharge points on both sides and the outlet of the funnel The front and rear horizontal distances can be adjusted without increasing the ...

Embodiment 3

[0054] see Figure 6-9 The unloading trolley shown with a material distribution device includes a climbing ladder 1, a pressure pulley 2, a frame 3, a trough roller group 4, a reversing roller 5, a reversible belt conveyor 24, and a head unloading roller 7 , three-way funnel 18, distribution chute 9, maintenance platform 10, anti-belt deviation device 11, centralized lubrication device, three-way funnel shield 21, three-way flap 17; three-way funnel shield 21 is located at the three-way funnel 18 Surrounding the three-way funnel 18 from above and surrounding the three-way funnel 18, the upper periphery of the three-way funnel 18 is provided with an inspection platform 10;

[0055] The boat-type three-way flap 17 is located in the three-way funnel 18, and the three-way flap 17 is connected with the electric push rod 23 through a hydraulic transmission mechanism; Positions 19 and 20; two outlets are arranged below the funnel 18, and the two outlets are arranged side by side alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com