Energy saving ultra clear glass kiln

A technology of ultra-clear glass and kilns, applied in the field of kilns, can solve problems such as large reflow coefficient of kilns, glass defects, high energy consumption, etc., and achieve good energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

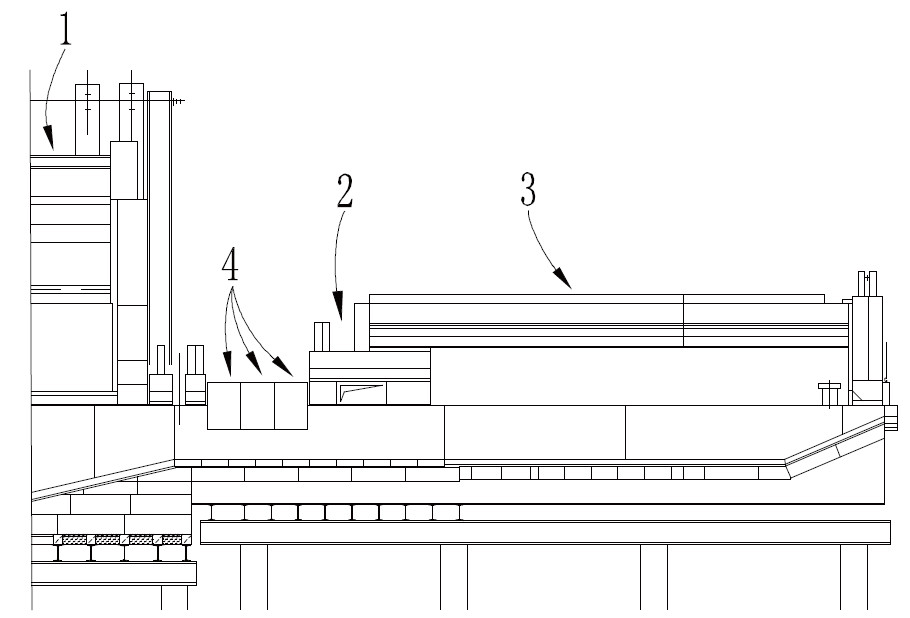

[0022] In order to explain the problem clearly and concisely, the melting zone is in figure 1 , figure 2 are not shown.

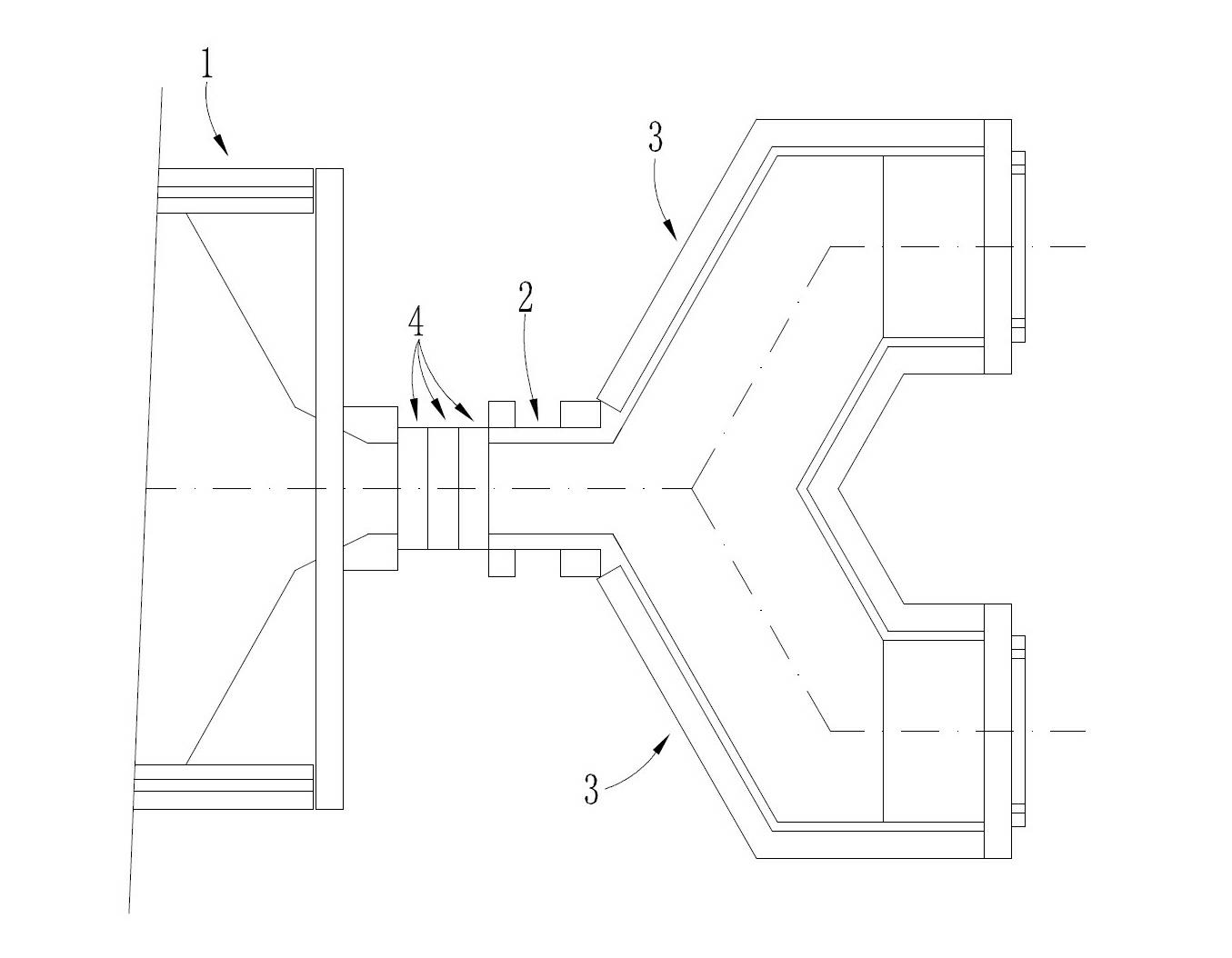

[0023] see figure 1 - Figure 4 , The kiln includes a melting zone, a clarification zone 1, a neck 2 and two cooling branch passages 3 connected in sequence, and the two cooling branch passages 3 become independent cooling parts.

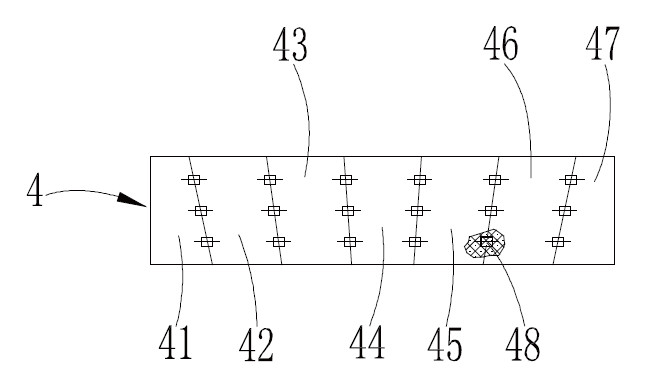

[0024] The clamp neck 2 has a width of 2000mm and a length of 4300mm. The neck 2 is provided with a glass liquid deep layer separation device, and the glass liquid deep layer separation device is three groups of rectangular parallelepiped horizontal retaining walls 4, and the two ends of each group of retaining walls 4 are supported on both sides of the pool wall in the width direction of the neck 2 above, and the ends of each group of retaining walls 4 are sealed and matched with the pool wall on the corresponding side, the bottom surface of each group of retaining walls 4 is between 1 / 2 of the depth direction of the neck 2...

Embodiment 2

[0030] In order to explain the problem clearly and concisely, the melting zone is in Figure 5 not shown in

[0031] see Figure 5 , the kiln includes four cooling branch passages 3 and successively connected melting zone, clarification zone 1, and two clamping necks 2, each clamping neck 2 is connected with two cooling branch passages 3, and the four cooling branch passages 3 become independent cooling section. Each neck 2 is provided with a glass liquid deep layer separation device, and the specific structure of the glass liquid deep layer separation device is the same as that of Embodiment 1, and will not be repeated here.

[0032] The width of each neck 2 is 2000mm and the length is 5000mm. The width of the cooling branch passage 3 is 2430mm, the pool depth is 800mm, and the area of the cooling part per ton of molten glass (discharge) is only 0.13m 2 .

[0033] This furnace is an ultra-clear glass furnace with one furnace and four lines. Compared with the existing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com