Seawater-based fracturing fluid and preparation method thereof

A technology of seawater and base pressure, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as difficult to meet fracturing construction, and achieve good temperature resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

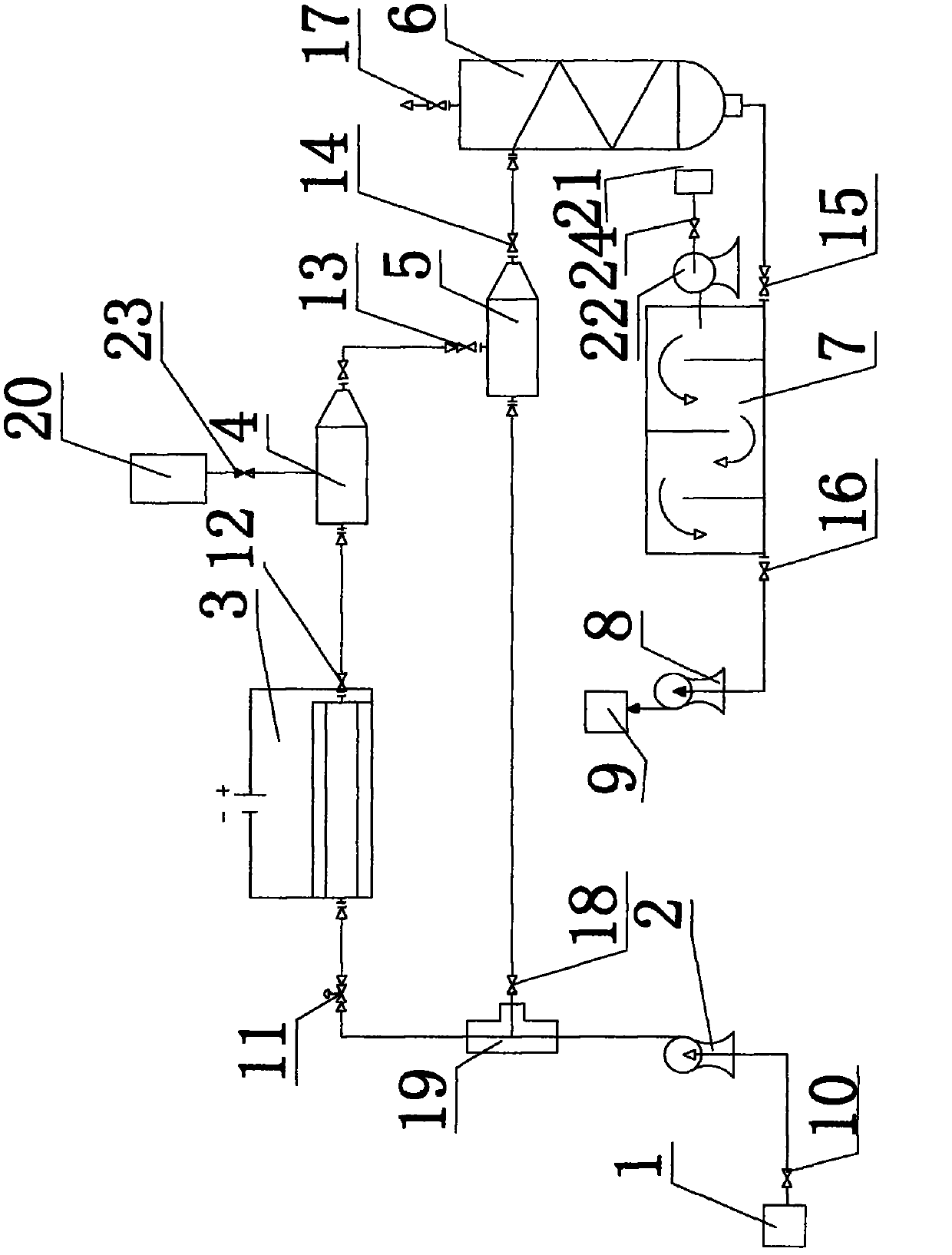

Method used

Image

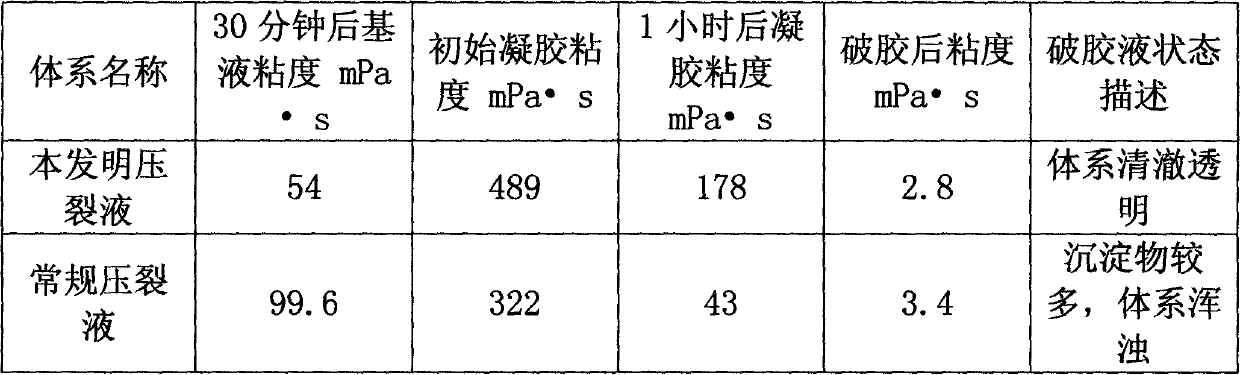

Examples

preparation example Construction

[0021] A preparation method of seawater-based fracturing fluid, comprising the steps of:

[0022] 1. Preparation of thickener: 15-30 parts of alkylacrylamide, 1-10 parts of 2-acrylamido-2-methylpropanesulfonic acid, 0.5-10 parts of vinylpyrrolidone, N, N-methylenebispropylene 0.1-3 parts of amide monomer, 47-83.4 parts of pure water, after nitrogen deoxygenation for 10-60 minutes, add 0.005-0.08 parts of initiator, polymerize for 3-8 hours at a temperature of 30-70°C, and then add 0.1-5 parts of basic catalyst and 1-10 parts of formaldehyde are reacted at a temperature of 40-80°C for 1-6 hours, dried and pulverized to obtain dry thickener powder;

[0023] 2. Preparation of cross-linking agent: one or more of the cross-linking agent zirconium oxychloride, zirconium tetrachloride, aluminum chloride and isopropanol, ethylene glycol, glycerin, citric acid, acetylacetone, glacial acetic acid One or more of lactic acid, malonic acid, sodium hydroxide and triethanolamine are dissolv...

Embodiment 1

[0026] Prepare 5000 grams of the present invention, its preparation method is as follows:

[0027] 1. Preparation of thickener: Take 30g of alkylacrylamide, 5g of 2-acrylamido-2-methylpropanesulfonic acid, 2g of vinylpyrrolidone, 0.1g of N, N-methylenebisacrylamide monomer and 62.9 parts of purified water , after nitrogen deoxygenation for 30 minutes, add 0.03g initiator, at a temperature of 50°C, polymerize for 8 hours, then add 1.1g of basic catalyst and 4.6g of formaldehyde, and react for 3 hours at a temperature of 70°C , dried and pulverized to obtain dry powder, which is 40 grams.

[0028] 2. Preparation of crosslinking agent: Take 1.02g zirconium oxychloride, 0.69g aluminum chloride, 5.25g isopropanol, 1.31g ethylene glycol, 0.20g acetylacetone, 1.28g glacial acetic acid, 0.33g malonic acid and 4.92 g of water was dissolved and mixed uniformly to prepare a crosslinking agent, which was 15 grams.

[0029] 3. Preparation of seawater-based fracturing fluid: Use a measuri...

Embodiment 2

[0031] Prepare 2000 grams of the present invention, and its preparation method is as follows:

[0032] 1. Preparation of thickener: Take 13.5g alkylacrylamide, 9.0g 2-acrylamido-2-methylpropanesulfonic acid, 4.5g vinylpyrrolidone, 0.9g N, N-methylenebisacrylamide monomer and 62.1 g of pure water, after nitrogen deoxygenation for 30 minutes, add 0.009g initiator, at a temperature of 50°C, polymerize for 8 hours, then add 2.34g of basic catalyst and 0.9g of formaldehyde, at a temperature of 70°C, React for 3 hours, dry and pulverize to obtain dry powder, which is 30 grams.

[0033] 2. Preparation of crosslinking agent: Take 0.408g zirconium oxychloride, 0.276g aluminum chloride, 2.1g isopropanol, 0.522g ethylene glycol, 0.078g acetylacetone, 0.51g glacial acetic acid, 0.132g malonic acid and 1.974 g water is dissolved and mixed uniformly to obtain a crosslinking agent. is 6.0 grams.

[0034] 3. Preparation of seawater-based fracturing fluid: Use a graduated cylinder to measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com