Under-balanced underground casing valve plate and processing method thereof

A casing valve and underbalanced technology, which is applied in the direction of wellbore/well valve device, earthwork drilling and production, wellbore/well parts, etc., to achieve the effect of simple and feasible processing method and increased thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

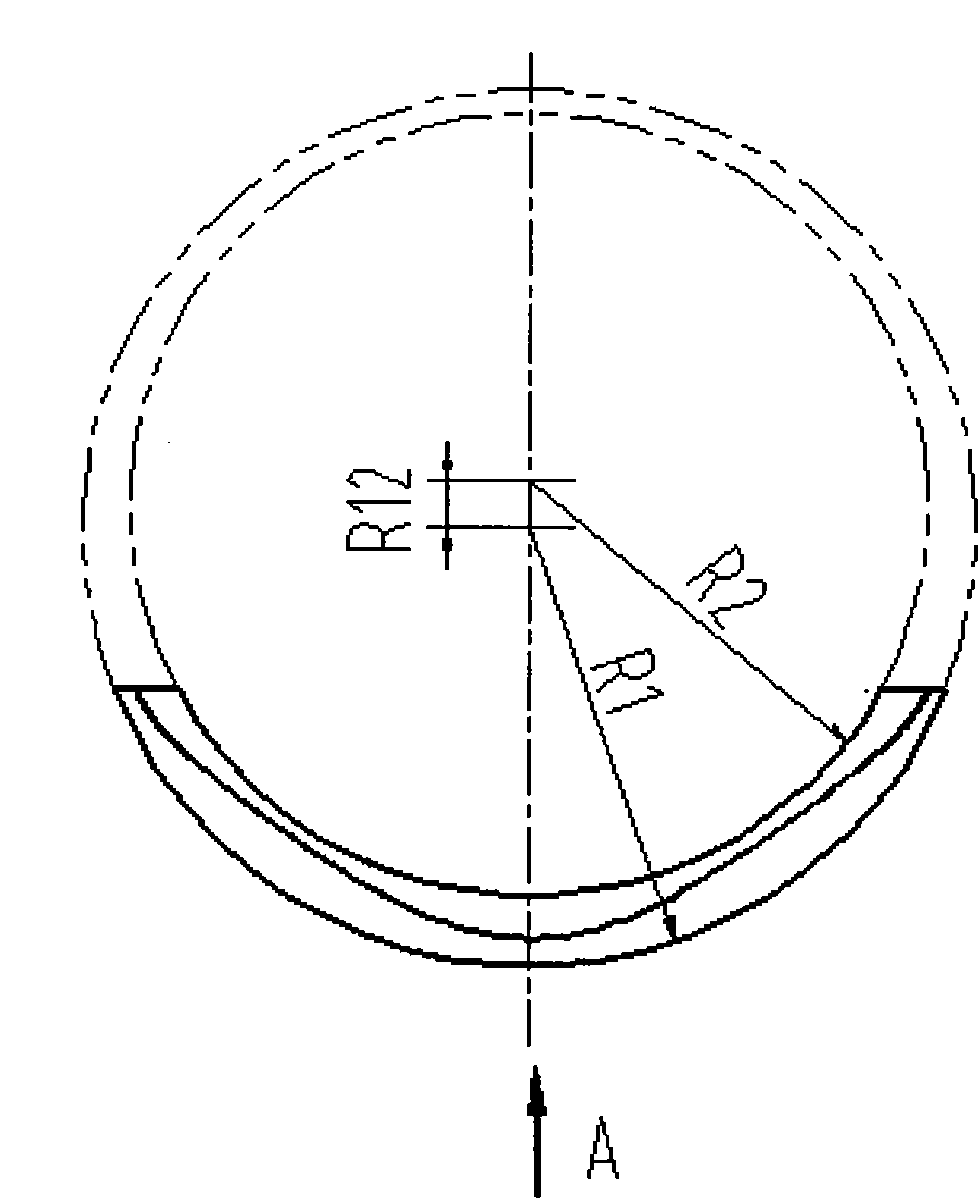

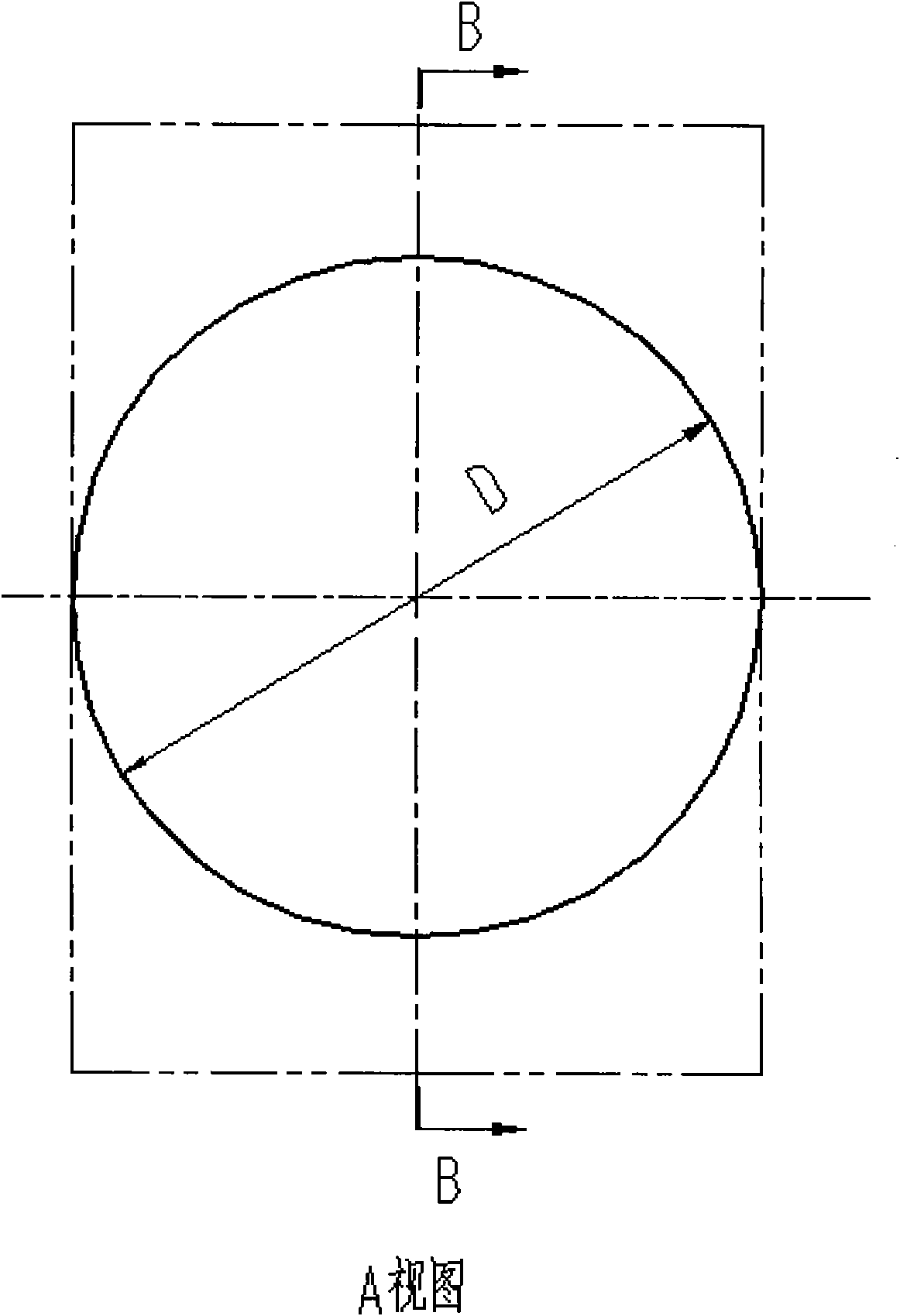

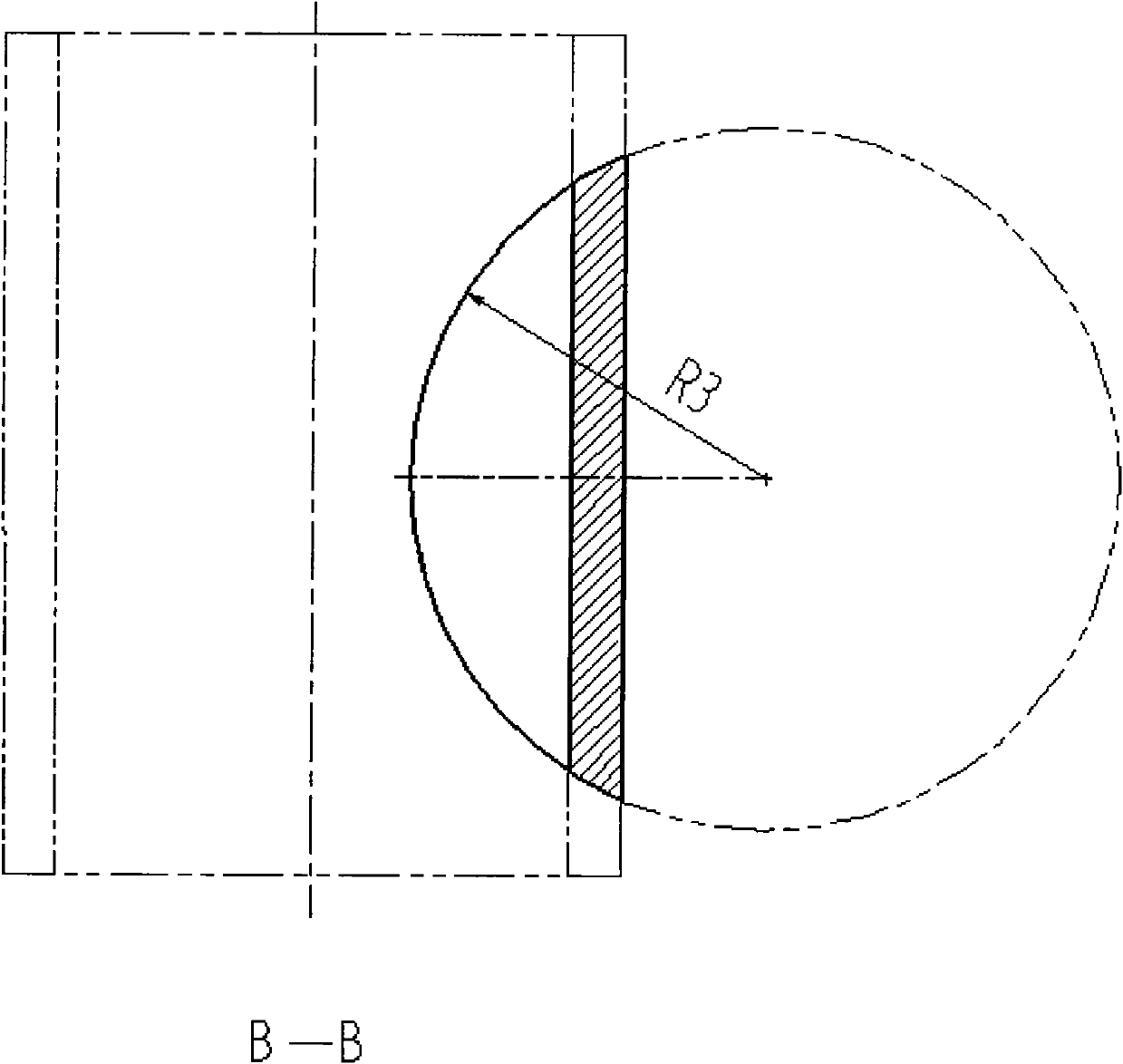

[0019] Embodiment 1: An underbalanced downhole casing valve valve plate, which is an internal intercept of an eccentric cylinder (outer circle radius R1, inner circle radius R2, eccentricity R12) and two cylindrical surfaces, one of which is The surface (radius R3) is perpendicular to the symmetric plane of the eccentric cylinder, the projection of the intersecting body is an arch, and the rotation axis of the other cylindrical surface (diameter D) is on the symmetric plane of the eccentric cylinder and perpendicular to the axis of the eccentric cylinder, the intersecting body The projection of is a circle.

Embodiment 2

[0020] Embodiment 2: Processing the valve plate of an underbalanced downhole casing valve specifically includes the following steps:

[0021] (1) Take a cylindrical blank, fix the inner cylinder, and rotate the blank to produce the radius size R1 of the outer circle of the eccentric ring;

[0022] (2) Fix the outer cylinder, and rotate the tool to bore out the radius size R2 of the inner circle of the eccentric ring;

[0023] (3) Spot weld a tooling on the outer surface, clamp the tooling with a chuck, and rotate the valve plate to form a bow-shaped outer edge radius R3 on the side of the valve plate;

[0024] (4) Turn over the tooling and clamp it with a chuck, and rotate the valve plate to drive out the diameter D of the circular outer edge of the valve plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com