Three-primary-color-principle-based ultra-high-brightness light-emitting diode (LED) white light mixing method

A three-primary color principle and ultra-high technology, applied in the field of ultra-high-brightness LED mixed white light, can solve problems such as difficulty in mixing light, increasing usage, etc., and achieve the effect of solving heat dissipation problems, good constant current performance, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

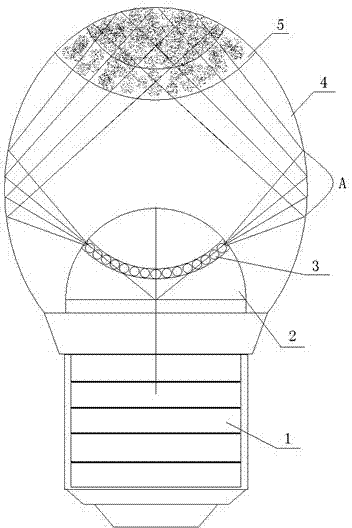

[0029] Such as figure 1 As shown, the ultra-high-brightness LED mixed white light method based on the principle of three primary colors, it at least includes the inner seat 2, the outer shell 4 and the driving circuit, and the inner seat 2 is distributed with three kinds of RGB LEDs distributed in proportion, and the outer shell 4 covers it. On the seat 2, under the action of the drive circuit, the three kinds of RGB LEDs are respectively covered by the reflective surface A in the casing to the light-gathering surface on the casing according to the assigned divergence angle, and the RGB three kinds of LEDs are mixed into white light after being covered by the light-gathering surface 5. After being softened by the light-gathering surface 5, the white light with required color temperature is emitted outwards.

[0030] Three kinds of RGB LEDs are driven by the driving circuit in the lamp holder 1 to emit three colors of red, green and blue (RGB). The center of the semicircular i...

Embodiment 2

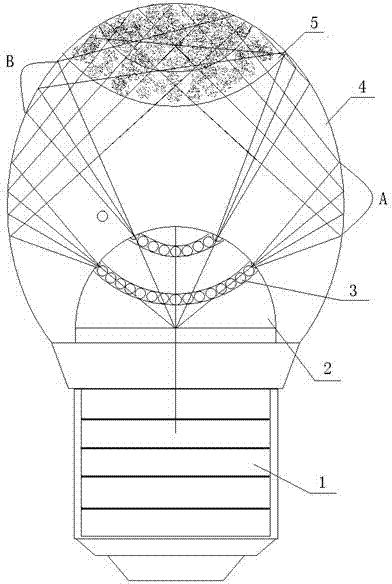

[0040] The hemispherical shape of the inner seat 2 is for the convenience of LED optical design, such as figure 2 In another structure, under this structure, the inner seat 2 also chooses a hemispherical shape, and there are two circles of LED base strips 10 in different layers of the hemisphere, and the two circles of LED base strips 10 respectively circle the main axis to form angles of the same size in different directions At this time, the size of the light-emitting surface of each LED to the reflective surface A is very close, and the size of the light-emitting surface to the reflective surface B is very close, that is, the LEDs from different layers to the reflective surface A and reflective surface B emit light at different levels. angle, but they all continue to diverge after being reflected by the reflective surface, and finally form the same area of coverage on the light-gathering surface 5, and finally emit white light. Embodiment 2 is more suitable for the desig...

Embodiment 3

[0044] When the LED base band 10 on the inner seat 2 only needs one turn, the inner seat 2 is annular, and the LED base band 10 is fixed on the inner seat 2 of the annular shape, and there is a drive circuit in the inner seat 2, and the LED base band 10 and the inner After the seat 2 is fixed, it is electrically connected to the drive circuit through the interface. The LED baseband 10 has two electrode connectors, one positive and one negative. LEDs of various wavelengths on the entire LED baseband 10 are connected in series. The outer shell 4 is connected with the inner seat 2 and then connected with the lamp holder 1, and the lamp holder 1 is a screw socket or a socket or a pin structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com