Engine balance shaft noise testing device

A technology of testing device and balancing shaft, which is applied in the direction of measuring device, testing of mechanical parts, testing of machine/structural parts, etc., can solve the problems of high requirements for places and test conditions, large volume, etc., and achieve the effect of reliable testing results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

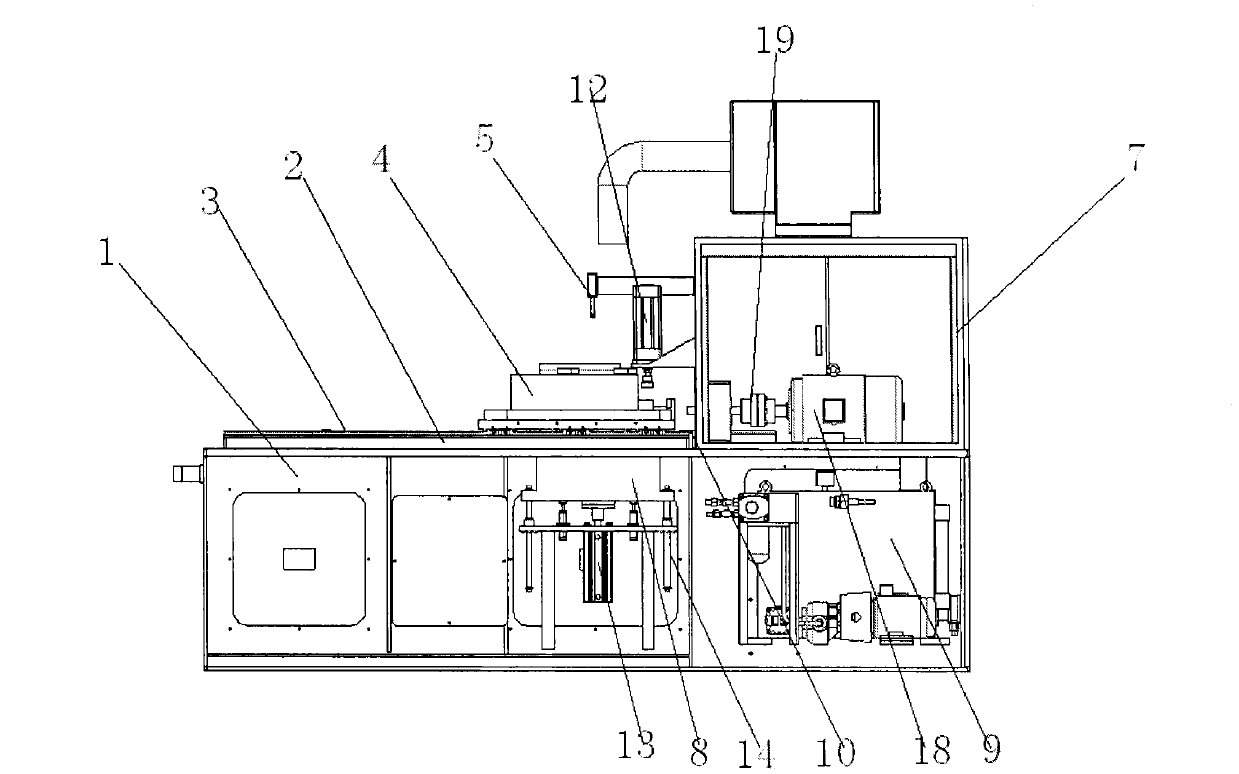

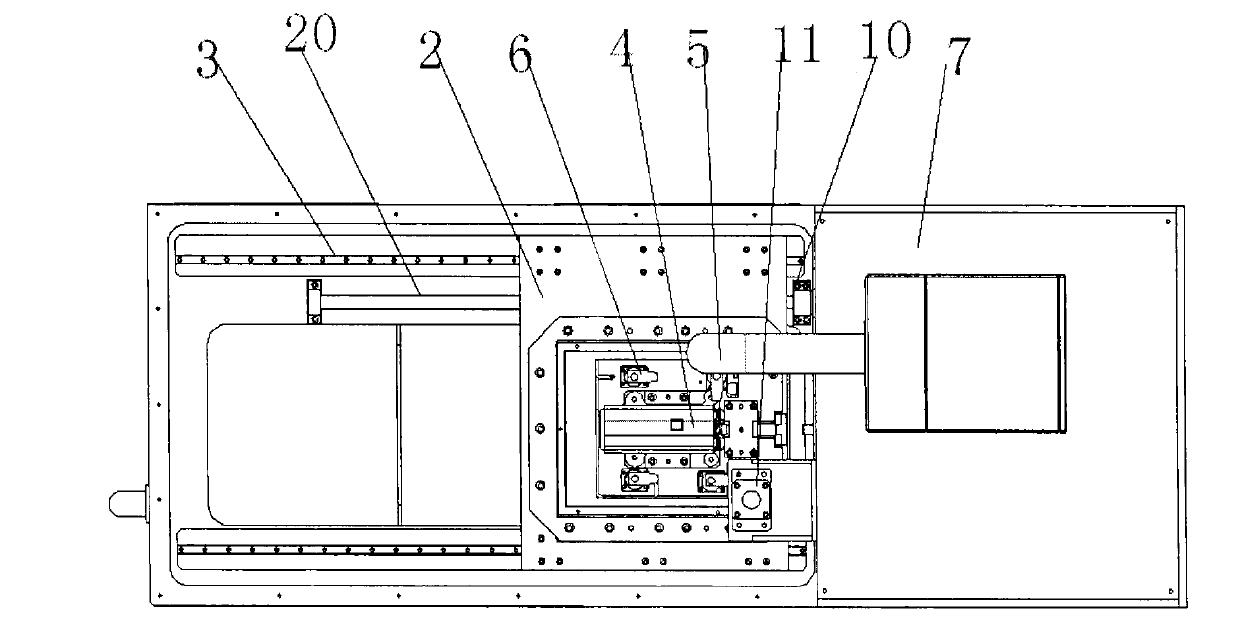

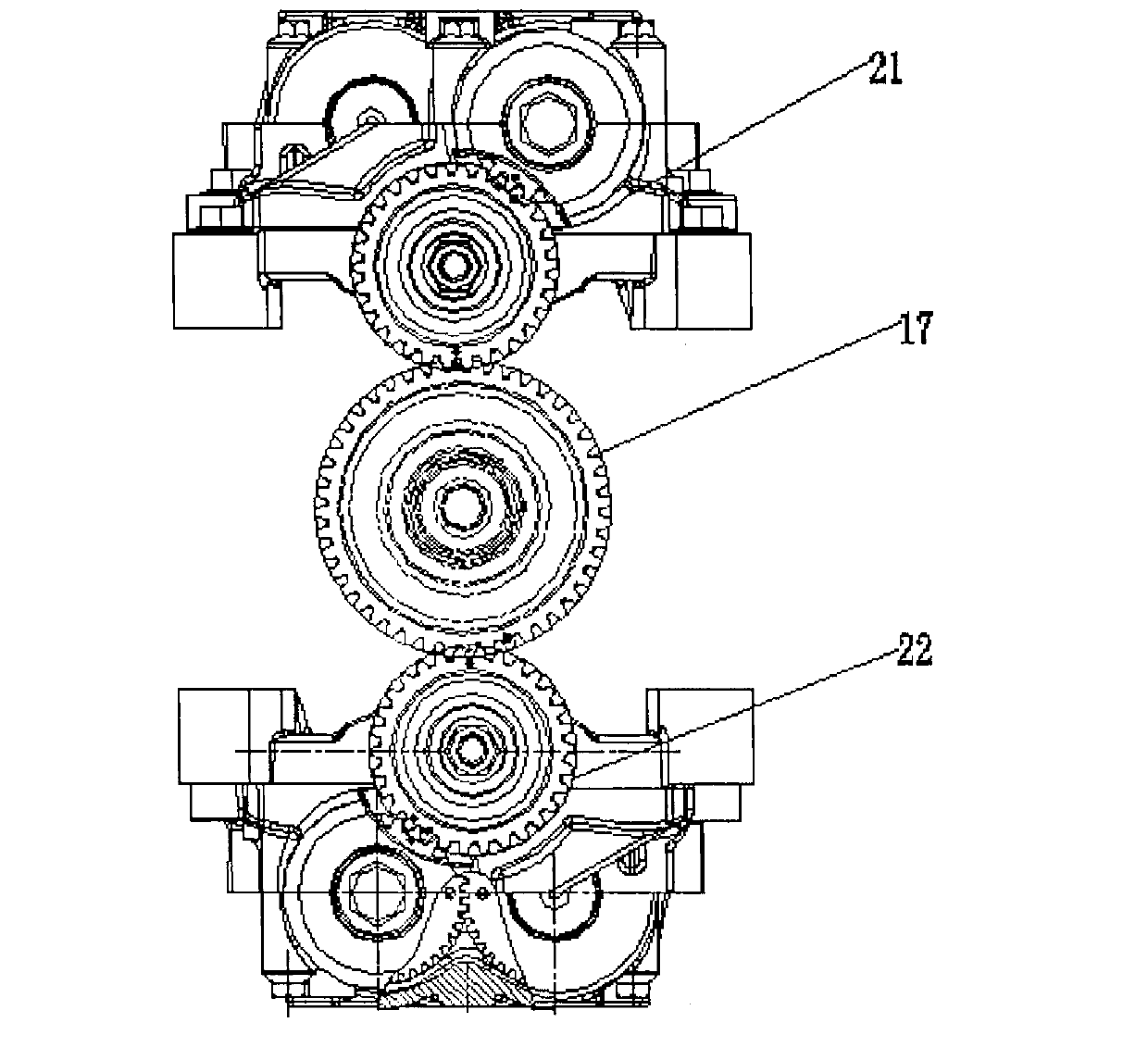

[0018] refer to Figure 1 to Figure 4 The shown engine balance shaft noise test device includes a base 1, a workbench 2, a guide rail 3 arranged on the workbench 2, a balance shaft positioning tool 4 slidably arranged on the guide rail 3, a balance shaft driving device 18, The balance shaft fixing device, the noise detection device 5, the test balance shaft 22, and the hydraulic system 9 that provides hydraulic oil at a certain pressure and temperature for the balance shaft 21 to be tested, the balance shaft fixing device is installed on the balance shaft positioning tool 4 The rotary compression cylinder 6 on the top, the accompanying test balance shaft 22 is set under the balance shaft positioning tool 4, the balance shaft drive device 18 is set in the box body 7 on the right side of the workbench 2, the noise detection device 5 is arranged on the side wall inside the box body 7, and the position corresponding to the noise detection device 5 under the workbench 2 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com