A large stroke steel coil lifting equipment

A technology with large strokes and steel coils, which is applied in the direction of hoisting devices and safety devices for lifting equipment, etc., can solve problems such as poor stability of oil cylinders, poor stability of pressure rods, and poor lifting heights, so as to reduce deformation of the frame and ensure good stress conditions , to counteract the effects of imbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

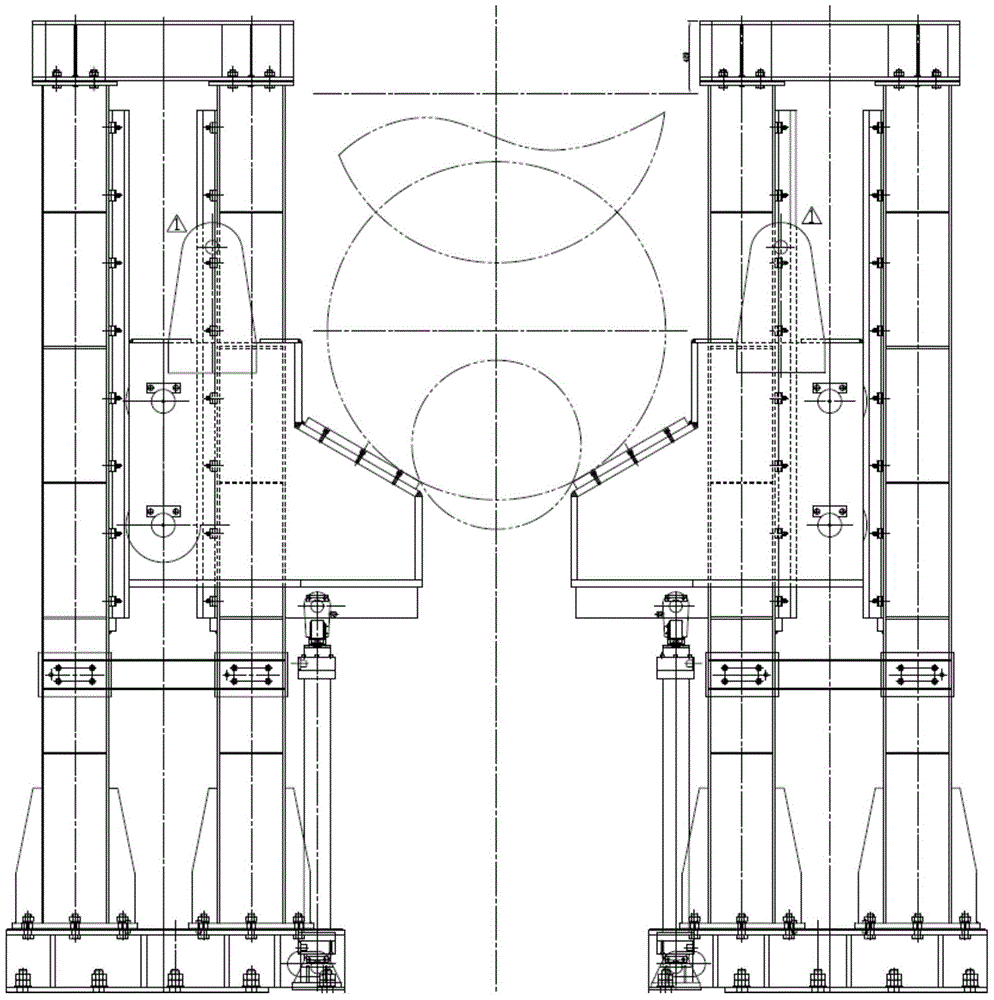

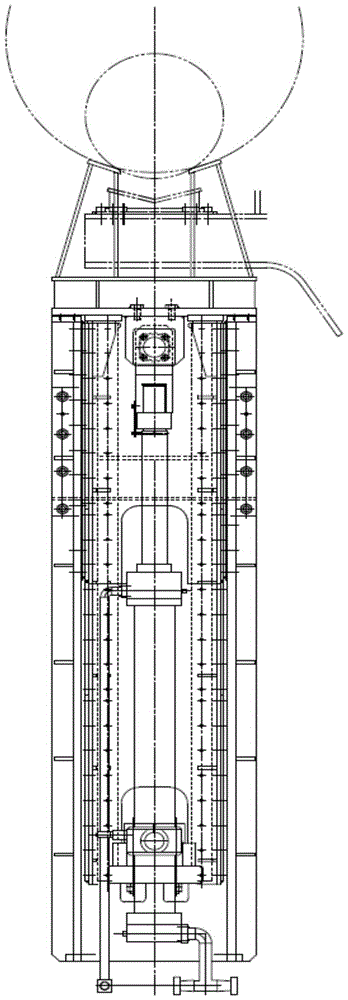

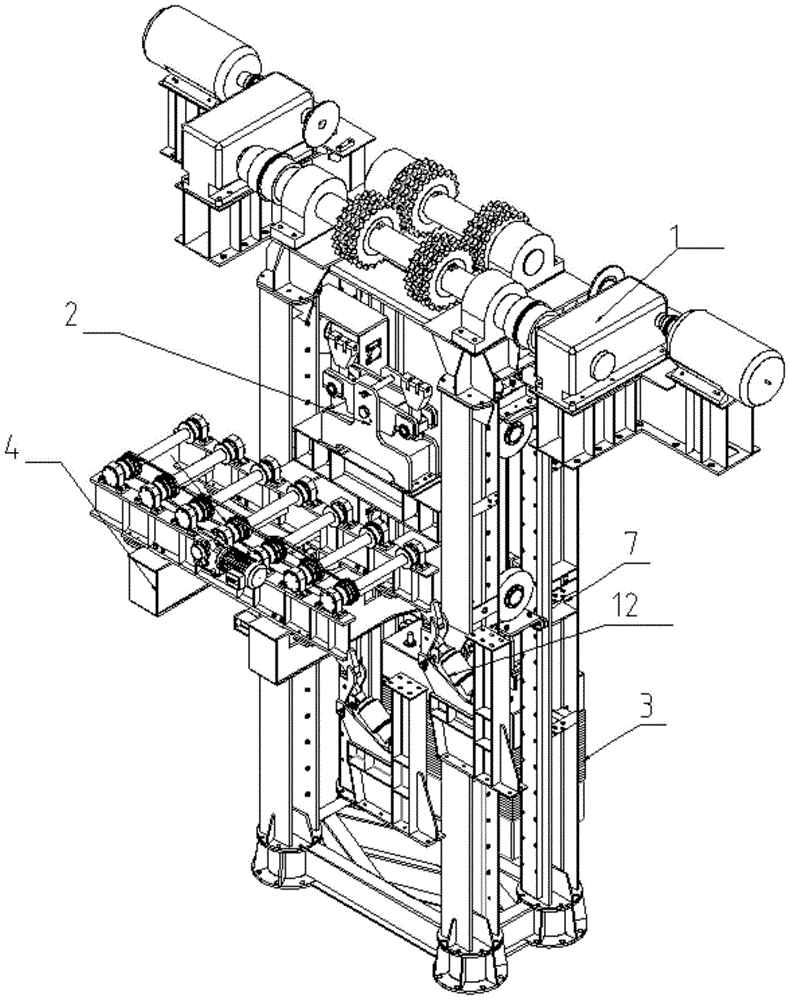

[0033] see Figure 3-Figure 9 , the present invention provides a kind of transport equipment for lifting and lowering metal strip volumes with a large stroke. 12. Automatic support device 5, frame 7, counterweight device 3, low support device 9, and horizontal support device 7a on the frame.

[0034] Working principle and structural features:

[0035] The driving device 1 of the present invention bears relatively large torque, so the driving device is placed on the foundation of the civil works, and the counter torque generated by the reducer and the motor is absorbed by the civil works;

[0036] Pallets and steel coils are placed on the lifting roller table to move up and down with the lifting platform, and the lifting roller table is seated on the lifting platform, see Figure 7 ;

[0037] Adding a balance beam device 2 on the side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com