Liquid-spraying online dynamic balancing terminal suitable for large outer diameter external thread grinder spindle

A technology of external thread and large outer diameter, which is applied to the parts of grinding machine tools, static/dynamic balance test, thread cutting machine, etc. It can solve the problems of affecting the quality of processed workpieces, easy splashing of liquid, and affecting the effect, so as to improve processing Quality and processing efficiency, prevention of liquid splashing, effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

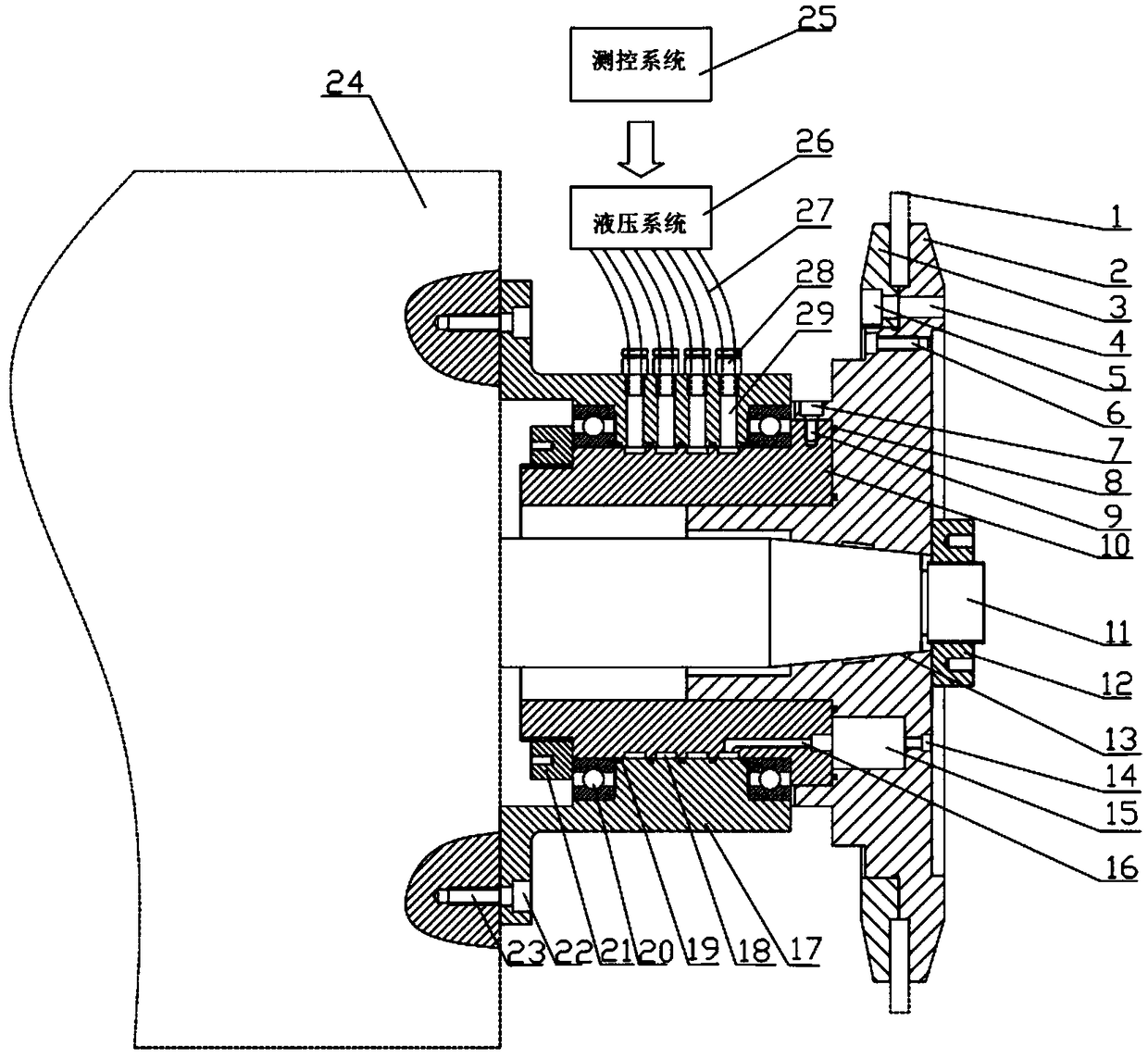

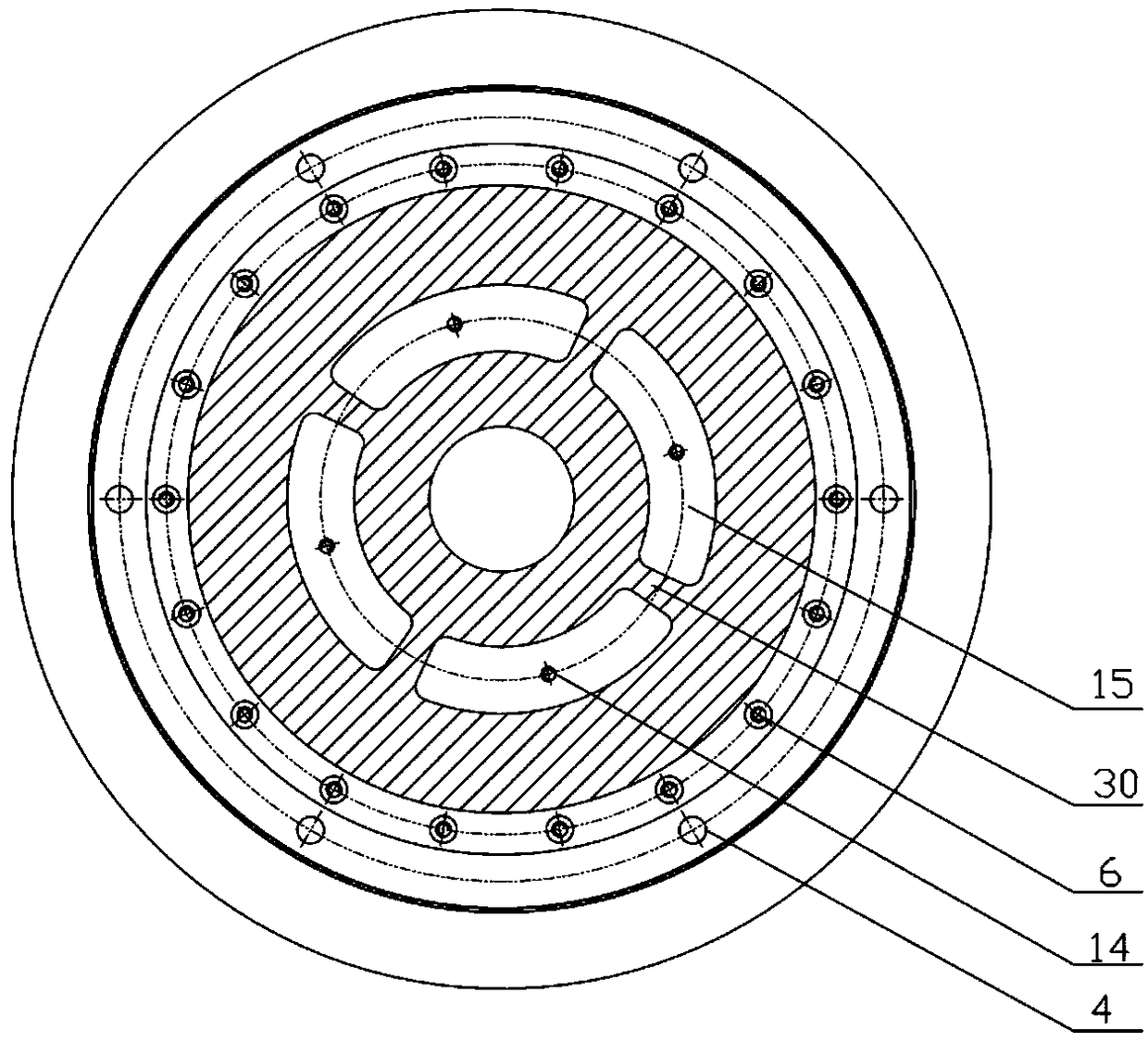

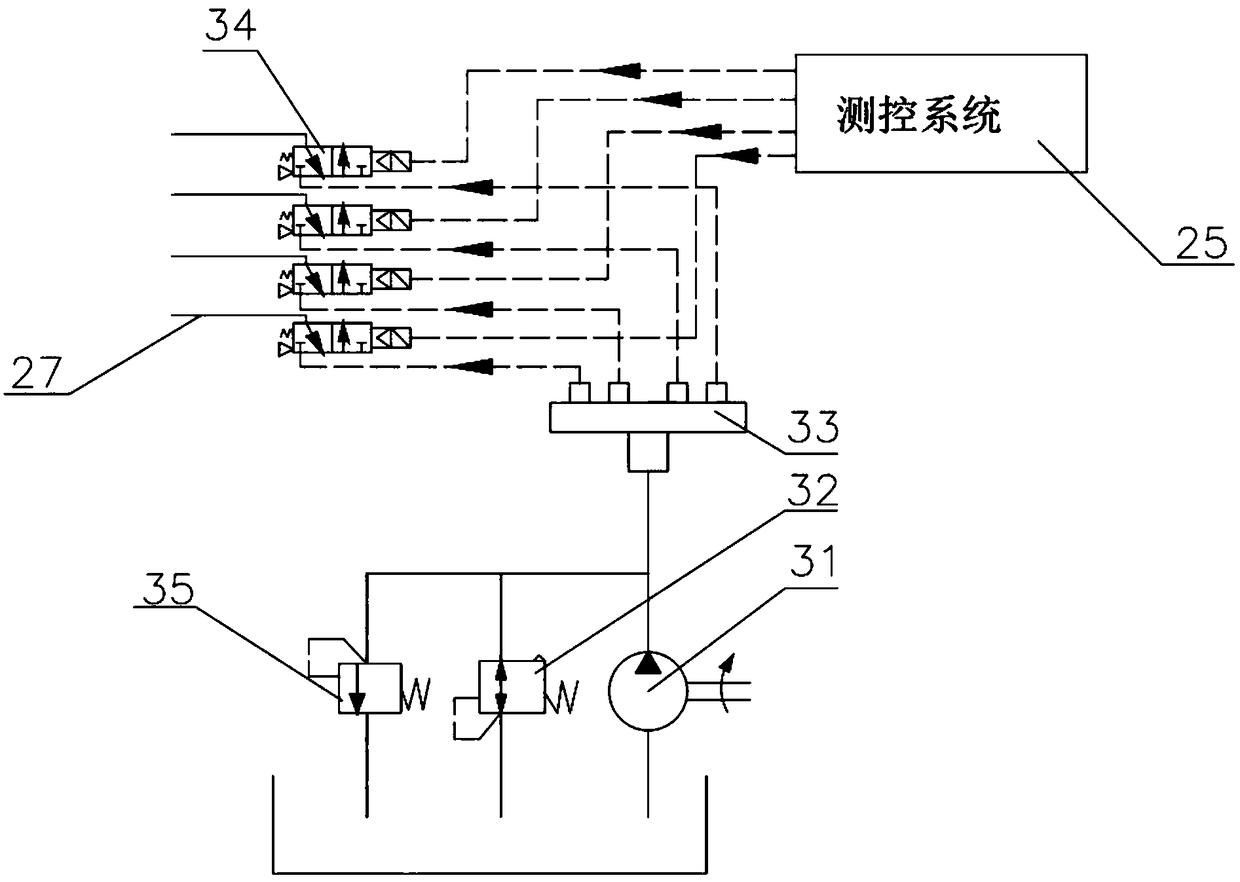

[0022] refer to figure 1 , figure 2 , a liquid-spraying online dynamic balance terminal suitable for the main shaft of a large-diameter external thread grinder, including a grinding wheel chassis 2, the central tapered hole 13 of the grinding wheel chassis 2 is connected with the taper of the main shaft 11, and is connected by a lock nut 12 Fasten the grinding wheel chassis 2 on the main shaft 11 to make the fit firm and reliable; the positions of the 6 countersunk through holes 5 on the grinding wheel chassis 2 and the 6 through holes 4 on the grinding wheel end cover 3 correspond to each other, and the bolts The grinding wheel chassis 2 is connected with the grinding wheel end cover 3, and the grinding wheel 1 installed between the grinding wheel chassis 2 and the grinding wheel end cover 3 is clamped at the same time;

[0023] The centra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com