A walking mechanism of a circular tube track robot and a circular tube track robot

A technology of orbital robots and walking mechanisms, applied to locomotives, manipulators, manufacturing tools, etc., can solve the problems of complex disassembly and assembly of straight bevel gears, loud noise of straight bevel gears, robot imbalance, etc., to improve life, reduce operating noise, improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

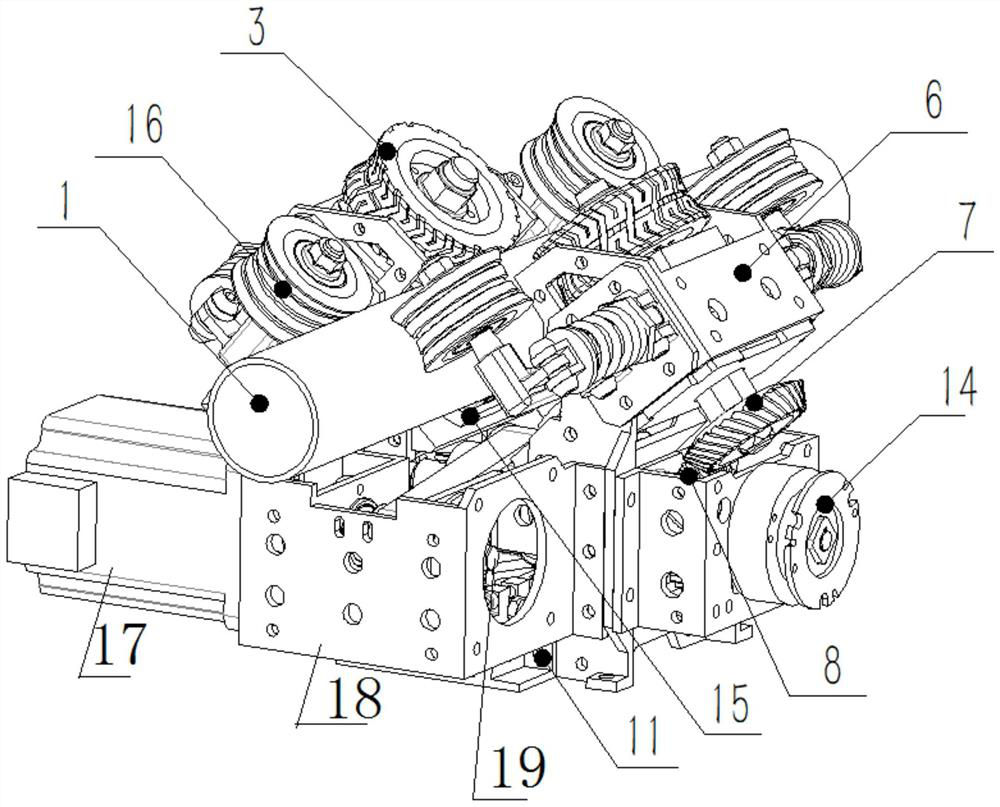

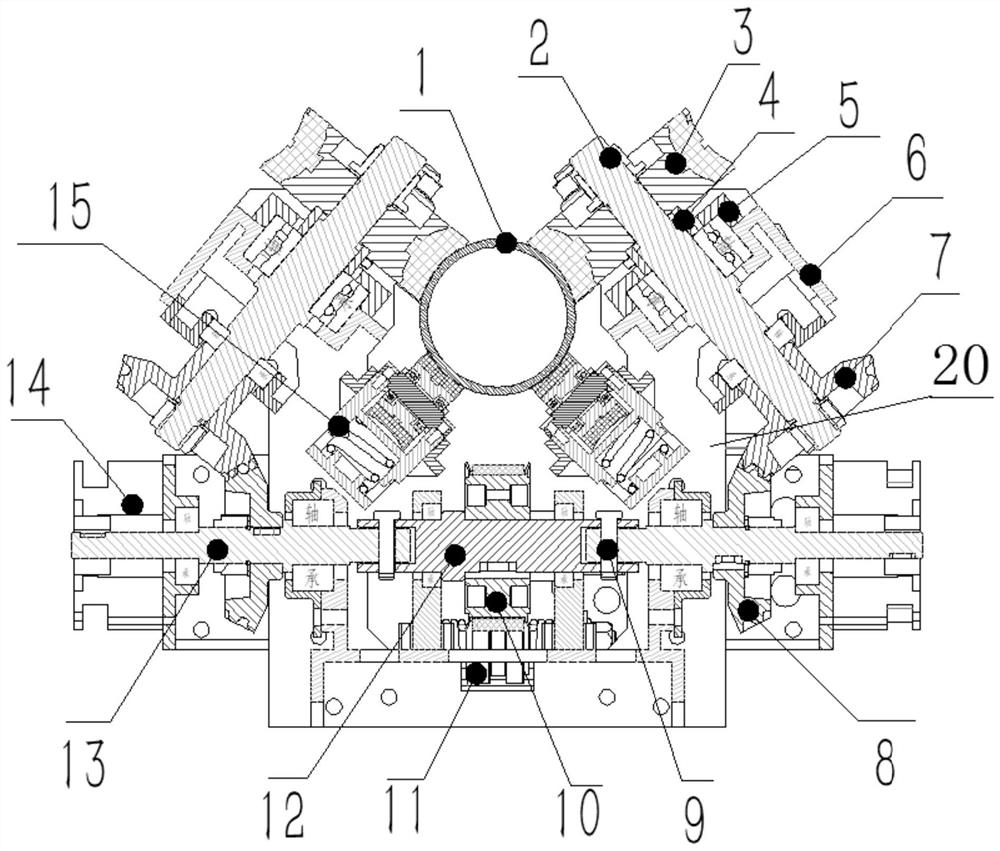

[0034] This embodiment provides a walking mechanism of a circular tube track robot, please refer to the attached figure 1 and figure 2 , the walking mechanism includes a power unit, a synchronous pulley transmission mechanism, a spiral bevel gear transmission mechanism, a guiding damping mechanism 16, a tight support mechanism 15, a tensioning wheel mechanism 11, a braking mechanism 14 and a driving wheel 3.

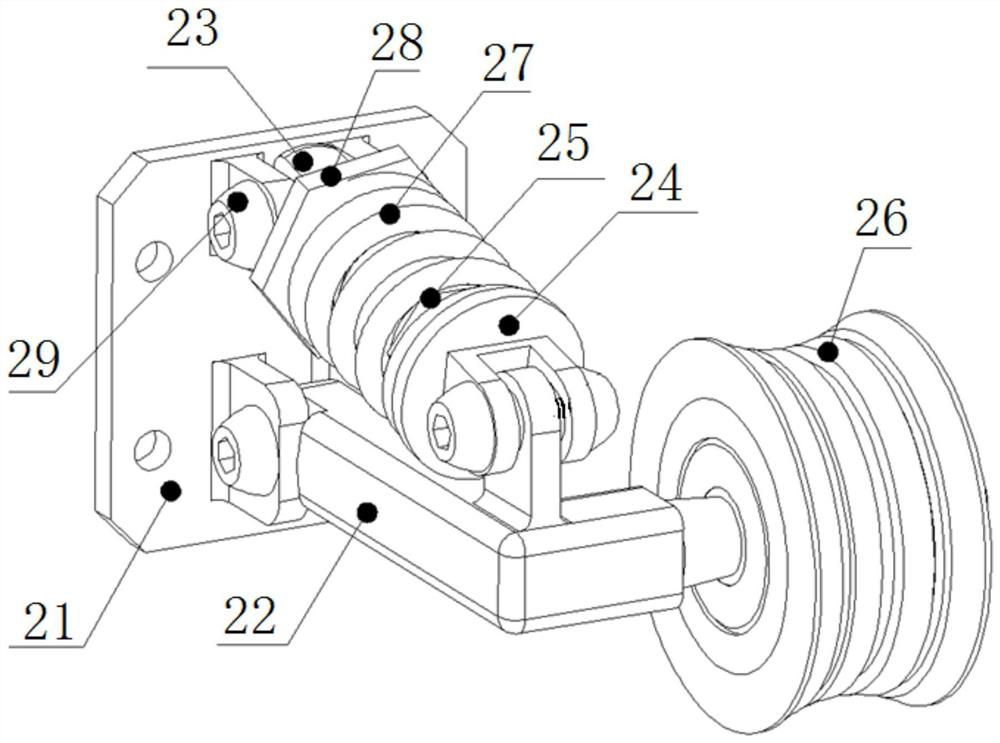

[0035] Please refer to the attached figure 1 , the power unit is realized by a stepper motor 17, the stepper motor 17 is fixed on the motor bracket 18, the motor connecting shaft 19 is fixed together with the active synchronous pulley in the form of a flat key, and the stepper motor 17 itself is The shaft is connected together with the motor connection shaft 19 through the flat mouth structure, so that the torque of the stepper motor 17 is transmitted to the driving synchronous pulley. The power generated by the stepping motor is transmitted to the driving wheel throu...

Embodiment 2

[0063] This embodiment also provides a round pipe orbital robot, the round pipe orbital robot includes such as Figure 1-2 The walking mechanism shown.

[0064] Wherein, for the specific structure of the running mechanism of this embodiment, please refer to the relevant descriptions of the previous embodiments, and details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com