Construction method for non-cantilever sections of sidespans of multiplex continuous beam or steel-constructed beam

A construction method and rigid structure technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as high safety risks, large investment, complex construction process, etc., and achieve obvious advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

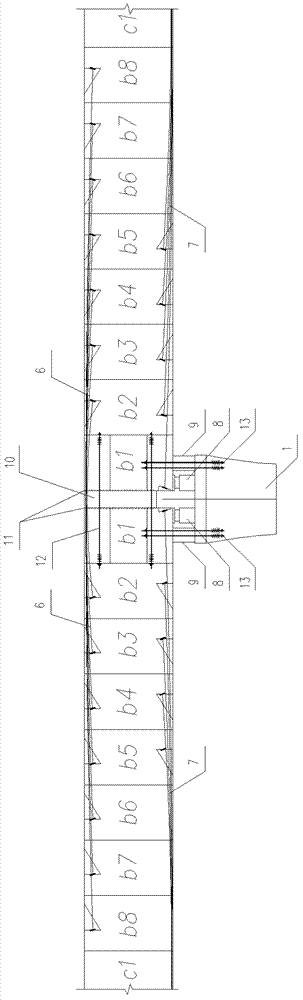

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

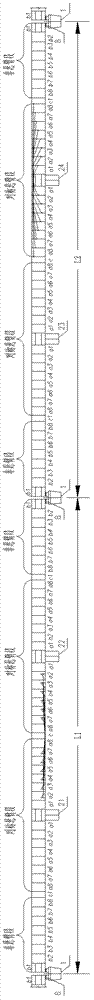

[0021] figure 1 A schematic diagram of the bridge span arrangement of 3 holes and 1 continuous (rigid frame) beam is shown, in which the bridge span layout form of each continuous (steel structure) beam is the same. Each continuous (rigid frame) beam is carried by two main piers (or rigid frame piers) and two side piers, for example, the first joint L1 has two main piers (or rigid frame piers) 21, 22, two side piers Pier 1 and the second joint L2 have two main piers (or rigid structure piers) 23 and 24, and two side piers 1, and the side piers 1 between the first and second joints are also two continuous junction piers.

[0022] Depend on figure 1 It can be seen that after the cantilever construction of the beam body is symmetrically carried out on the main piers 21, 22, 23, and 24, there must be non-cantilever section construction between the main piers 22, 23 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com