Inspection well with fixed ladder

An inspection well and fixed technology, applied in the field of inspection wells, can solve the problems of easy corrosion, affecting the stability and safety of climbing ladders, etc., and achieve the effect of not easy to lose, improve safety and service life, and not easy to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

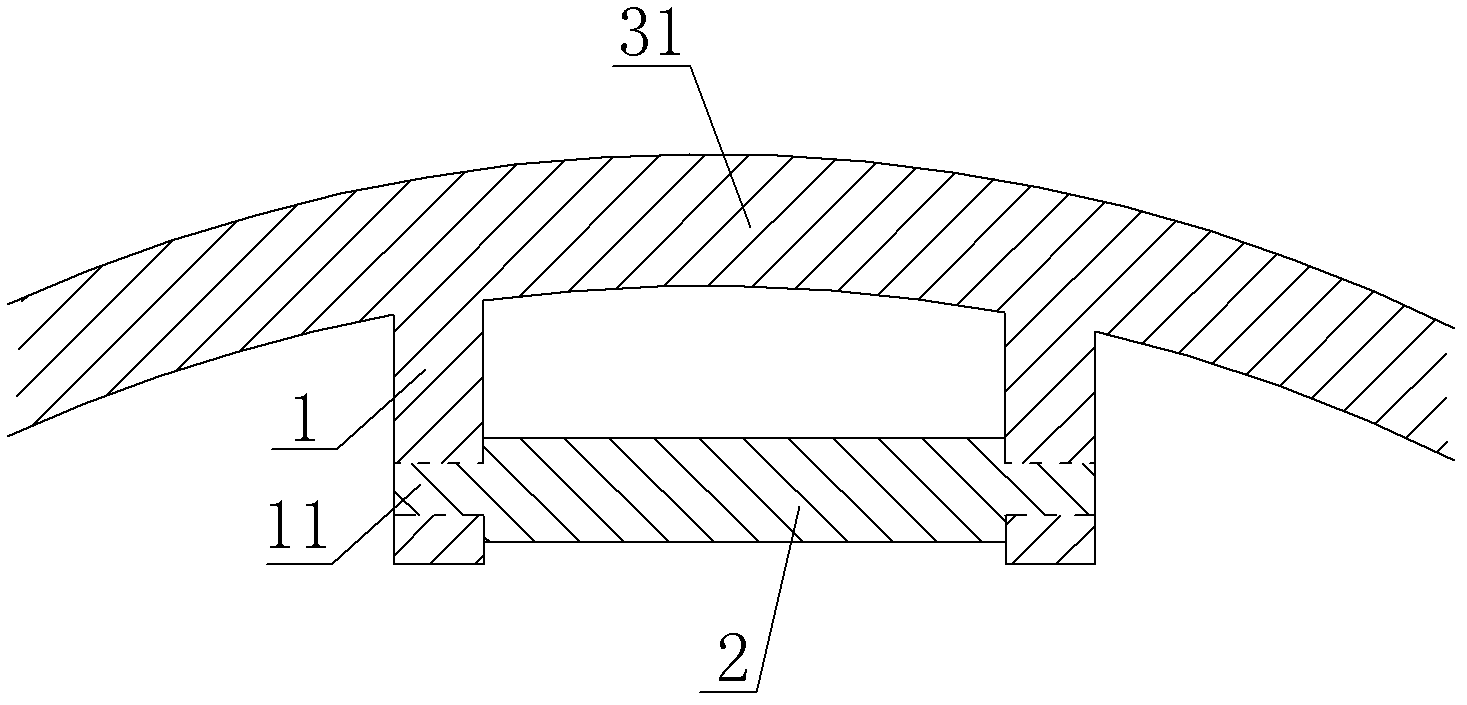

[0027] There are at least two through holes 11 arranged longitudinally on the side plate 1 to match the steps 2. The steps 2 are arranged horizontally and the two ends are respectively inserted in the through holes 11 of the two side plates 1 and connected to the side of the ladder. Board 1 solder connection. The stair side board can be a square board or a zigzag stair side board, and each sawtooth of the zigzag side board has a through hole 11 . When installing, use the elasticity of the plastic object itself to install the step 2 between the two stair side plates 1 and match the through hole 11 on the stair side plate 1, and finally connect the step 2 and the stair side plate 1 Do the welding.

Embodiment 2

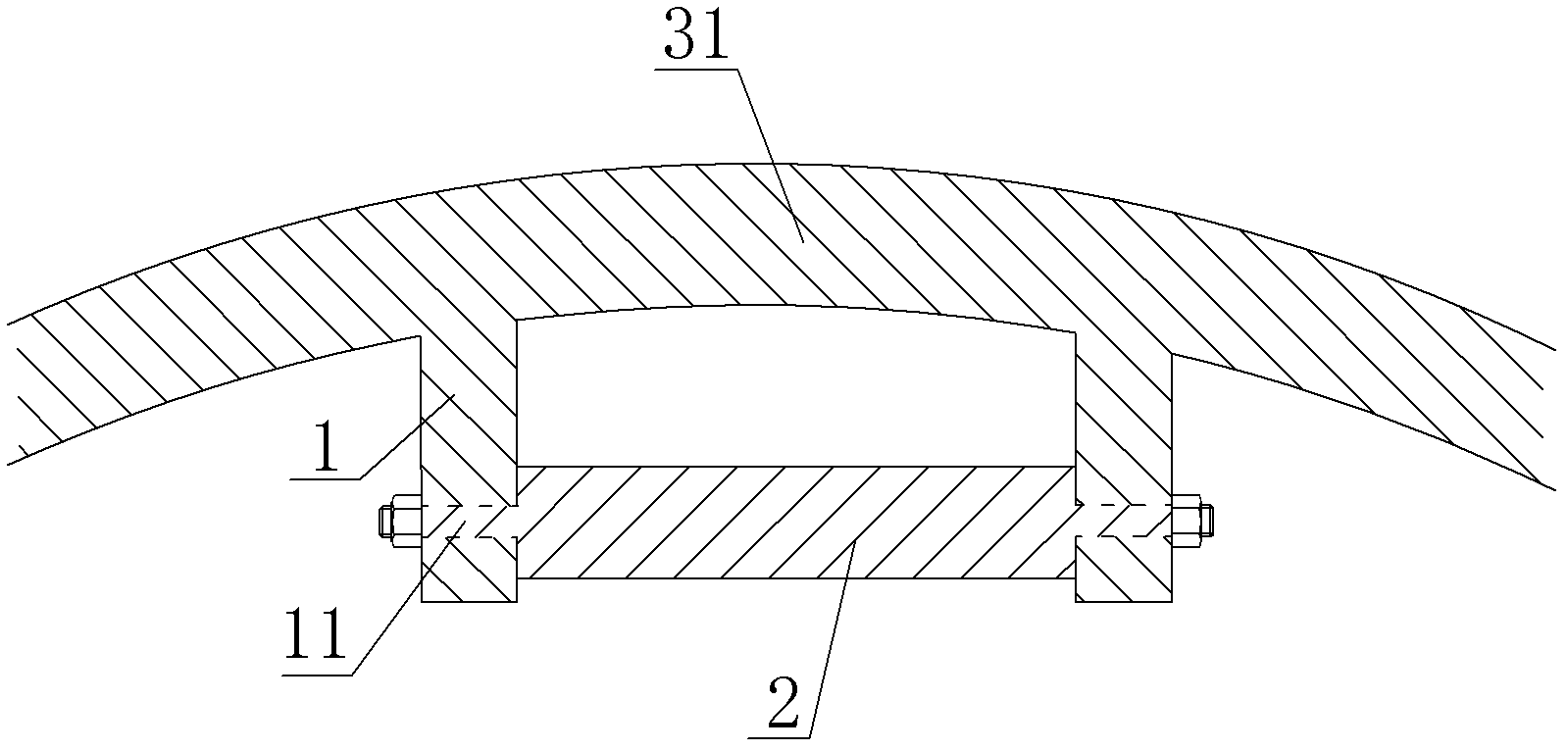

[0029] There are at least two through holes 11 arranged longitudinally on the side plate 1 to match the steps 2. The steps 2 are arranged horizontally and the two ends are respectively inserted in the through holes 11 of the two side plates 1 and connected to the side of the ladder. Board 1 is connected by screw caps. The side plate of the ladder is a zigzag side plate, and each sawtooth has a through hole 11 . The stair side board can be a square board or a zigzag stair side board, and each sawtooth of the zigzag side board has a through hole 11 . When installing, use the elasticity of the plastic object itself to install the step 2 between the two stair side plates 1 and match the through hole 11 on the stair side plate 1, and finally connect the step 2 and the stair side plate 1 Secure the connection with a screw cap.

Embodiment 3

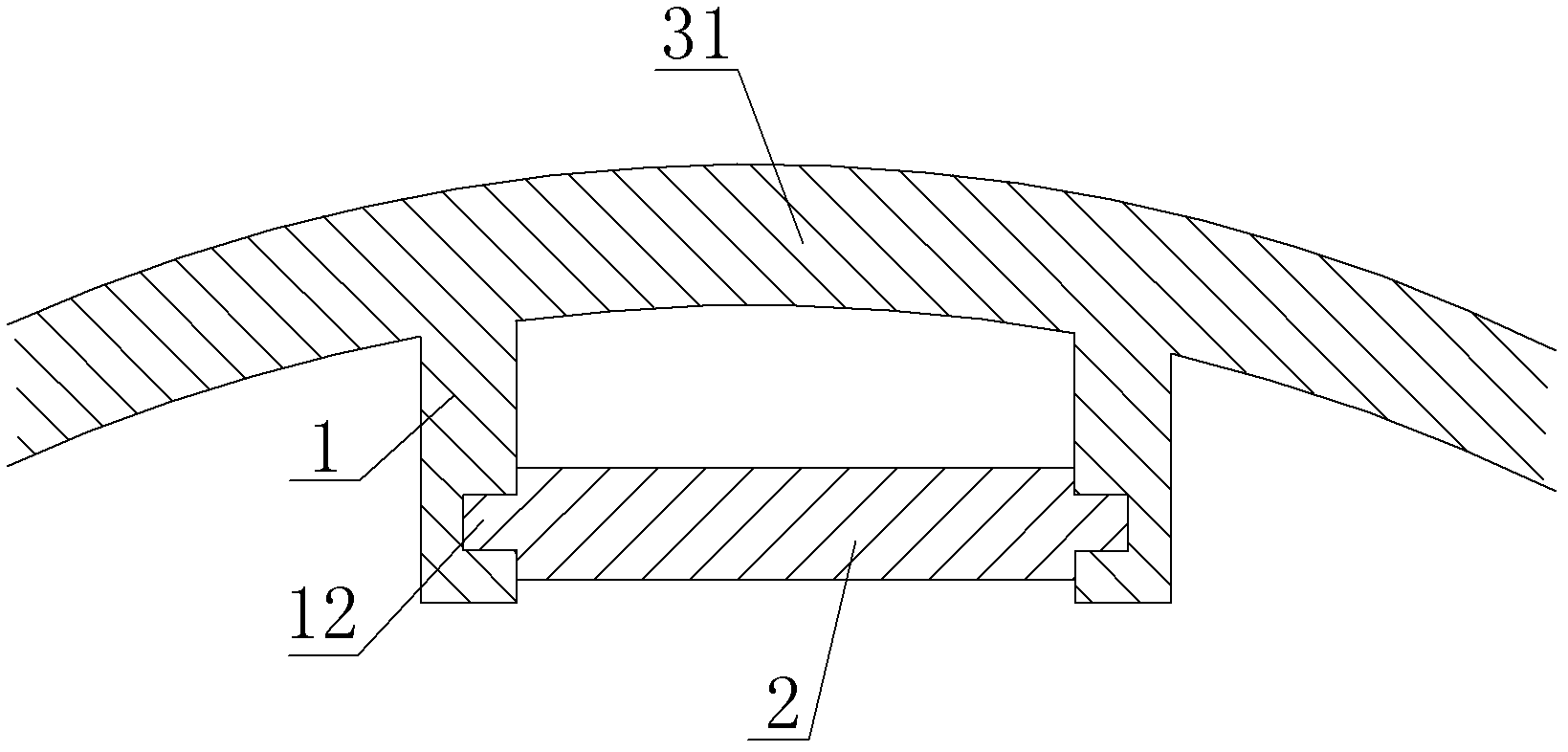

[0031] There are at least two longitudinally arranged notches 12 matched with the steps 2 on the side plate 1, the steps 2 are arranged horizontally and the two ends are inserted into the notches 12 of the two side plates 1 respectively Board 1 solder connection. The stair side boards can be square boards or zigzag side boards, and each sawtooth of the zigzag side boards has a notch 12 . When installing, use the elasticity of the plastic object itself to install the step 2 between the two stair side panels 1 and match it with the notch 12 on the stair side panel 1. Do the welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com