Tester for testing insulation low-temperature performance of superconducting electrical component

A technology for electrical components and low temperature performance, which is applied in the field of testing devices for testing the insulation low temperature performance of superconducting electrical components, can solve problems such as pipeline helium leakage, Paschen discharge accident, cracking, etc. The effect of high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

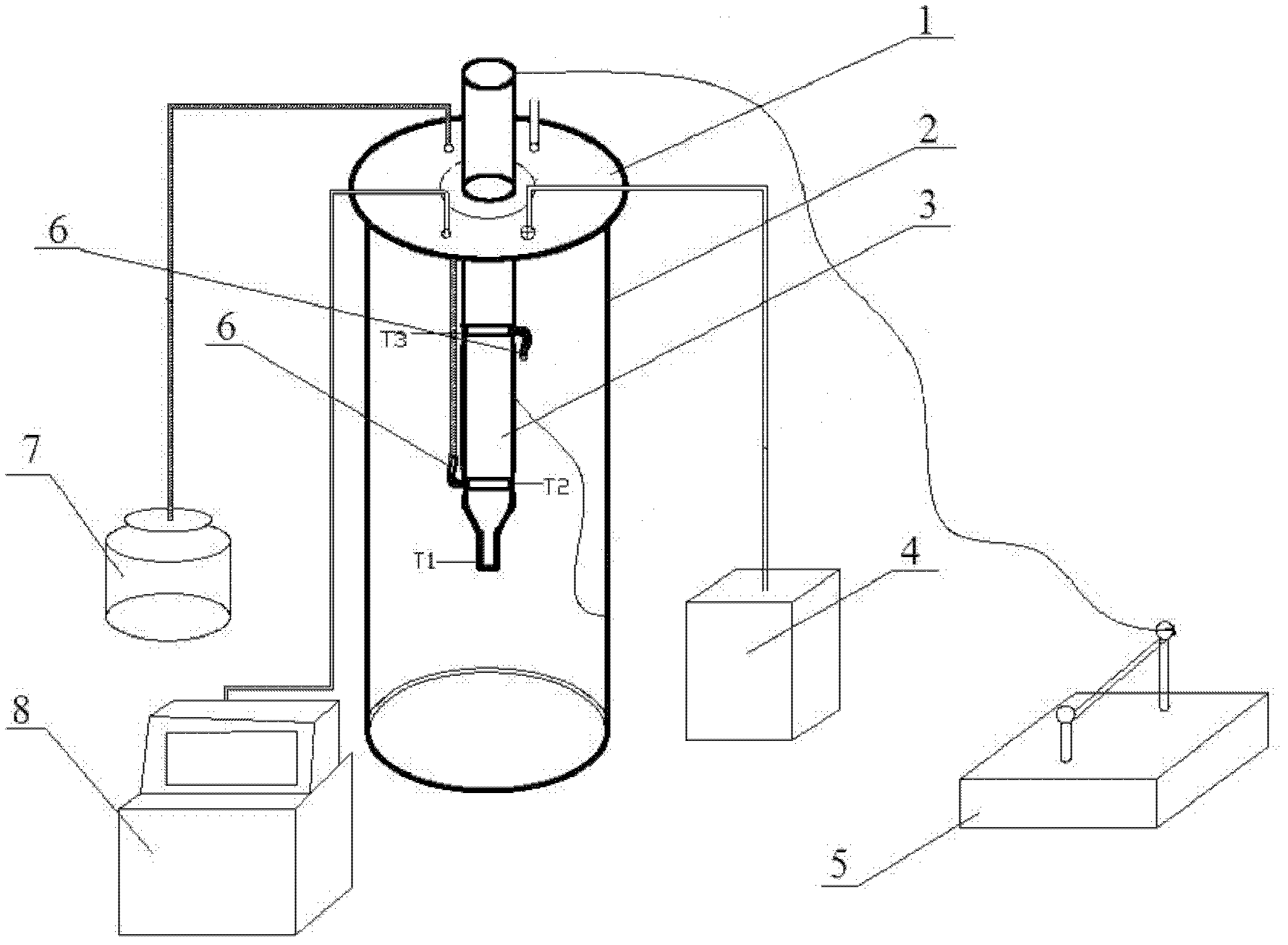

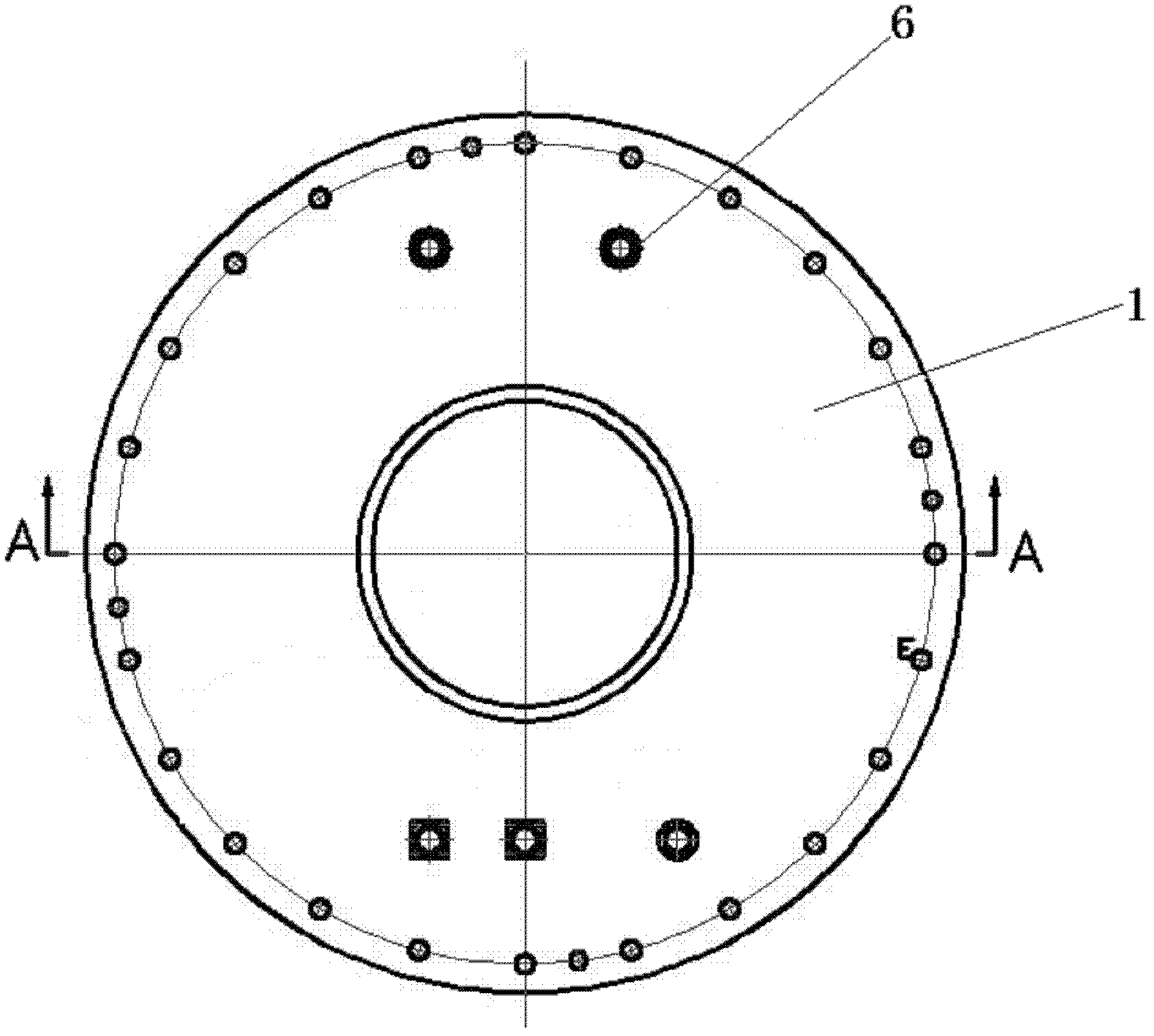

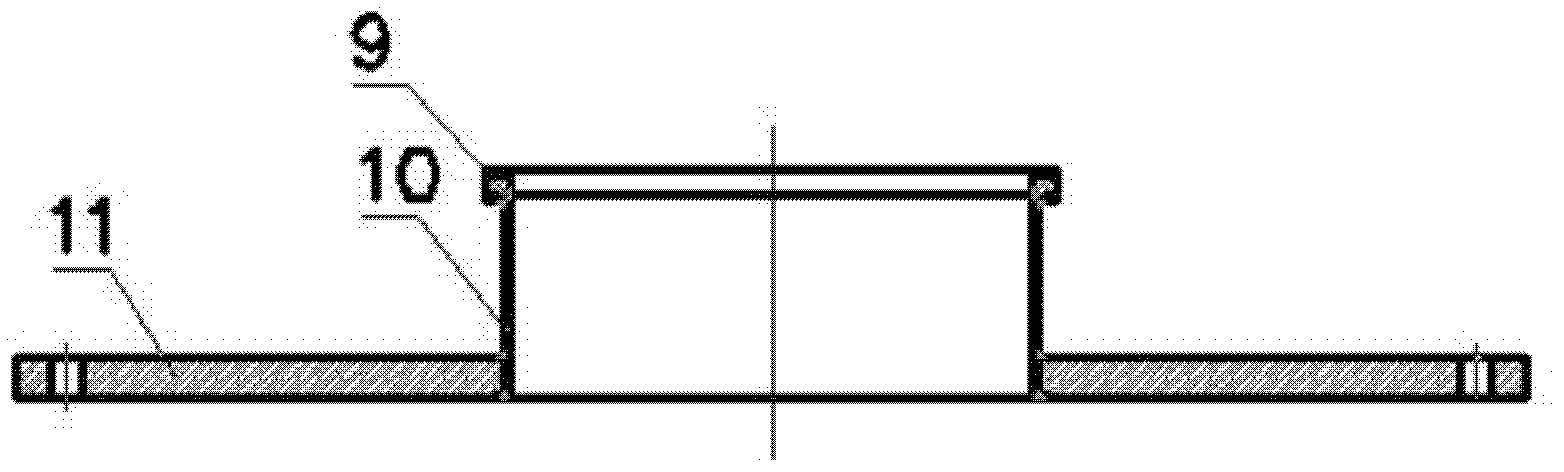

[0019] Referring to the accompanying drawings, a test device for checking the low-temperature insulation performance of superconducting electrical components includes a vacuum pressure vessel 2, a test vessel sealing flange 1 is installed on the top of the vacuum pressure vessel 2, and the test vessel sealing flange 1 includes Insulation test flange plate 11 for test parts matched with vacuum pressure vessel, insulation connection flange 9 for test parts, neck pipe 10 for insulation connection of test parts; low-temperature superconducting test part 3 is arranged in the vacuum pressure vessel, and the inner cavity of the vacuum pressure vessel is connected There is a vacuum pump 4, a cryogenic gas inlet and outlet 6 are respectively opened on the low-temperature superconducting test parts, and the cryogenic gas inlet and outlet 6 are connected to a cryogenic gas storage 7, which is a liquid nitrogen or liquid helium storage, and the cryogenic superconducting A temperature senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com