Method for computing safety tongs model node temperature using improved Heat flux density method for safety tongs of explosion-proof elevator

A technology of heat flux density and safety gear, which is applied in calculation, electrical digital data processing, special data processing applications, etc., can solve problems that have not been reported, and achieve accurate and reliable measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] To further explain the present invention, the manufacturing technology of this device is very clear to those in the field.

[0034] The following is to establish a finite element model through ABAQUS,

[0035] Heat flux model:

[0036] Estimation of instantaneous heat flux:

[0037] During the braking process of the safety gear, the gravitational potential energy and the change in kinetic energy of the system are converted into friction energy for the temperature rise of the entire system within the time t when the automatic operation starts.

[0038] Among them, the potential energy of gravity changes to:

[0039] W 1 =mg (1)

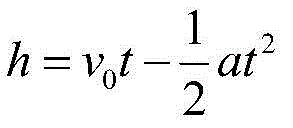

[0040] among them h = v 0 t - 1 2 at 2 .

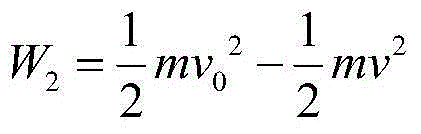

[0041] The change in kinetic energy is:

[0042] W 2 = 1 2 mv 0 2 - 1 2 mv 2 - - - ( 2 )

[0043] Where v=v 0 -at.

[0044] Therefore, the friction energy of the entire system:

[0045] W=(W 1 +W 2 )η (3)

[0046] Among them, η is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com