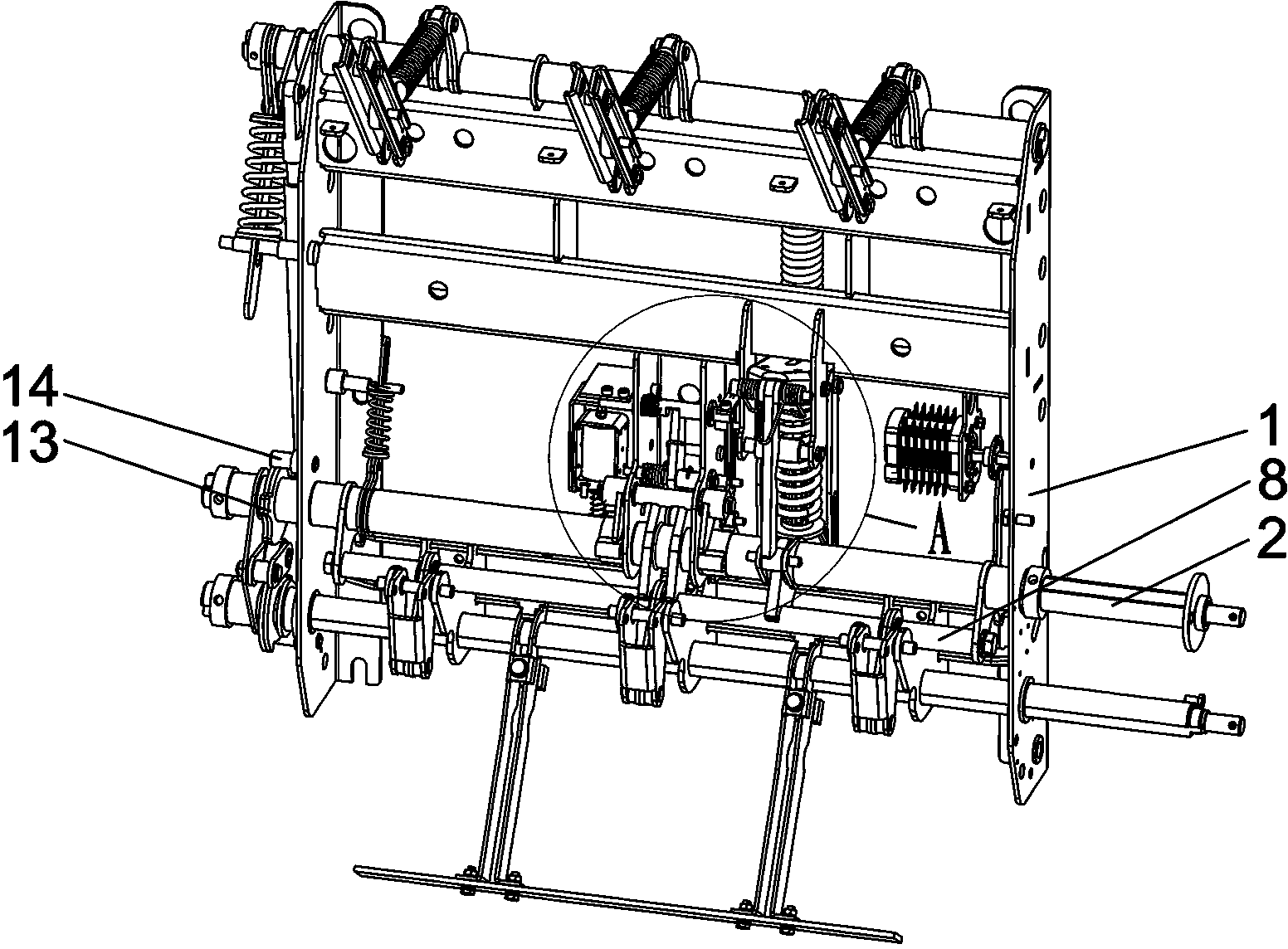

Spring energy storage mechanism for vacuum load switch

A technology of vacuum load and energy storage mechanism, which is applied to electric switches, high-voltage/high-current switches, high-voltage air circuit breakers, etc. It can solve problems such as large changes in characteristic parameters, many structural problems, difficult maintenance and debugging, etc., to achieve The effect of stable quality, optimized part design, and simple connection of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

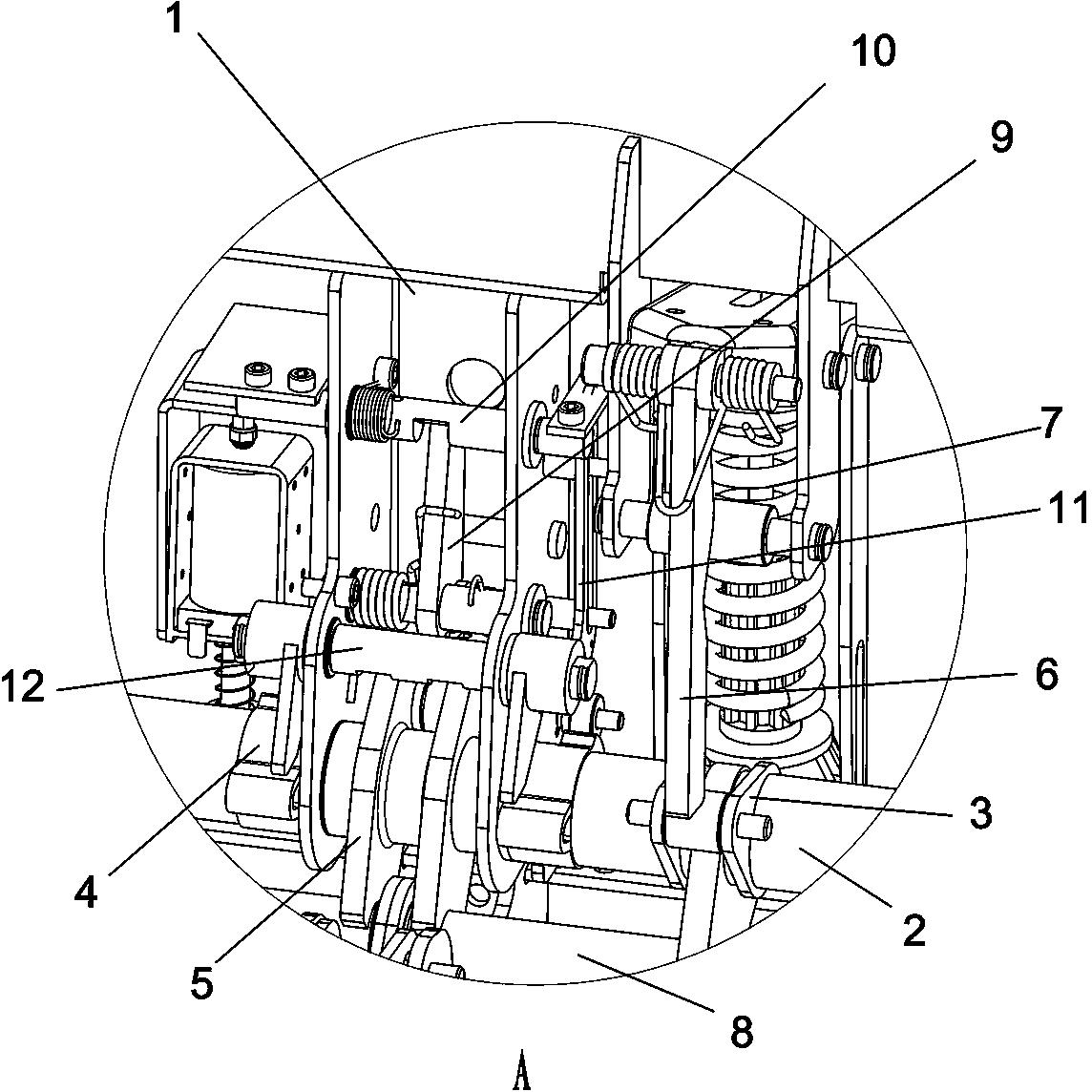

[0042] In another preferred embodiment, the main part of the opening ejector rod assembly 11 is the opening ejector rod 1101, and the lower end of the opening ejector rod 1101 is provided with the opening ejector rod pulley through the opening ejector pin 1102 provided thereon. 1103 is also provided with a small tension spring 1104 that pulls down the push rod 1101 of the gate.

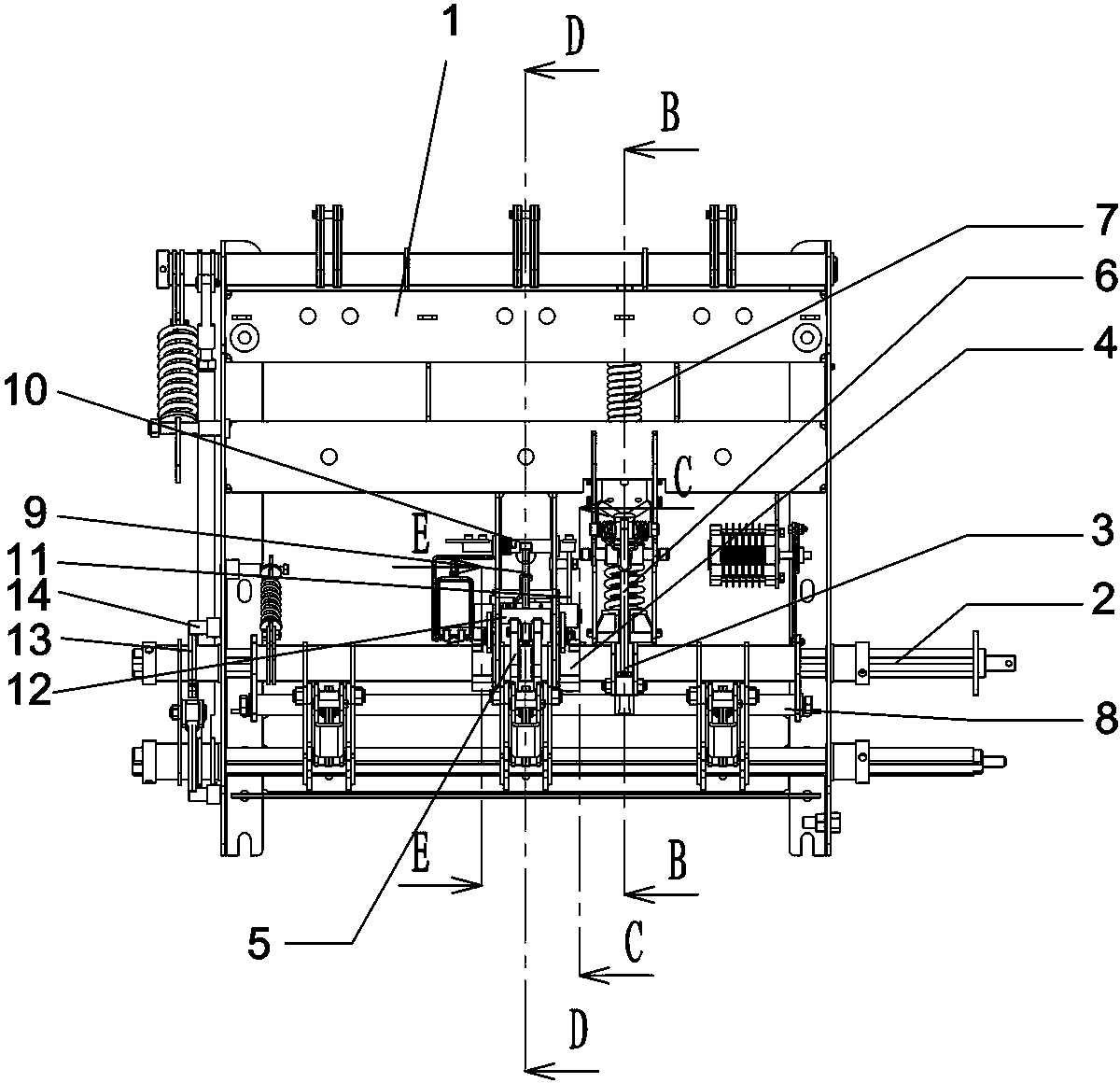

[0043] In another preferred embodiment, in order to prevent the main shaft from over-turning, the main shaft 2 is provided with a positioning protrusion 13 fixed on the main shaft 2 , and correspondingly, a positioning pin 14 of the positioning protrusion 13 is provided on the frame 1 .

[0044] In yet another preferred embodiment, the main shaft 2 is a circular shaft provided with a slot, and a shaft sleeve is installed on the main shaft 2 where no parts are provided.

[0045] The working principle of this embodiment will be introduced in detail below to illustrate the superiority of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com