Method for manufacturing ultra-stable ultra-high-fineness micro-optical cavity

A production method and fineness technology, which is applied in the field of micro-optical cavity, can solve the problems of low fineness of micro-optical cavity and cannot meet the measurement requirements, and achieve the effect of reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

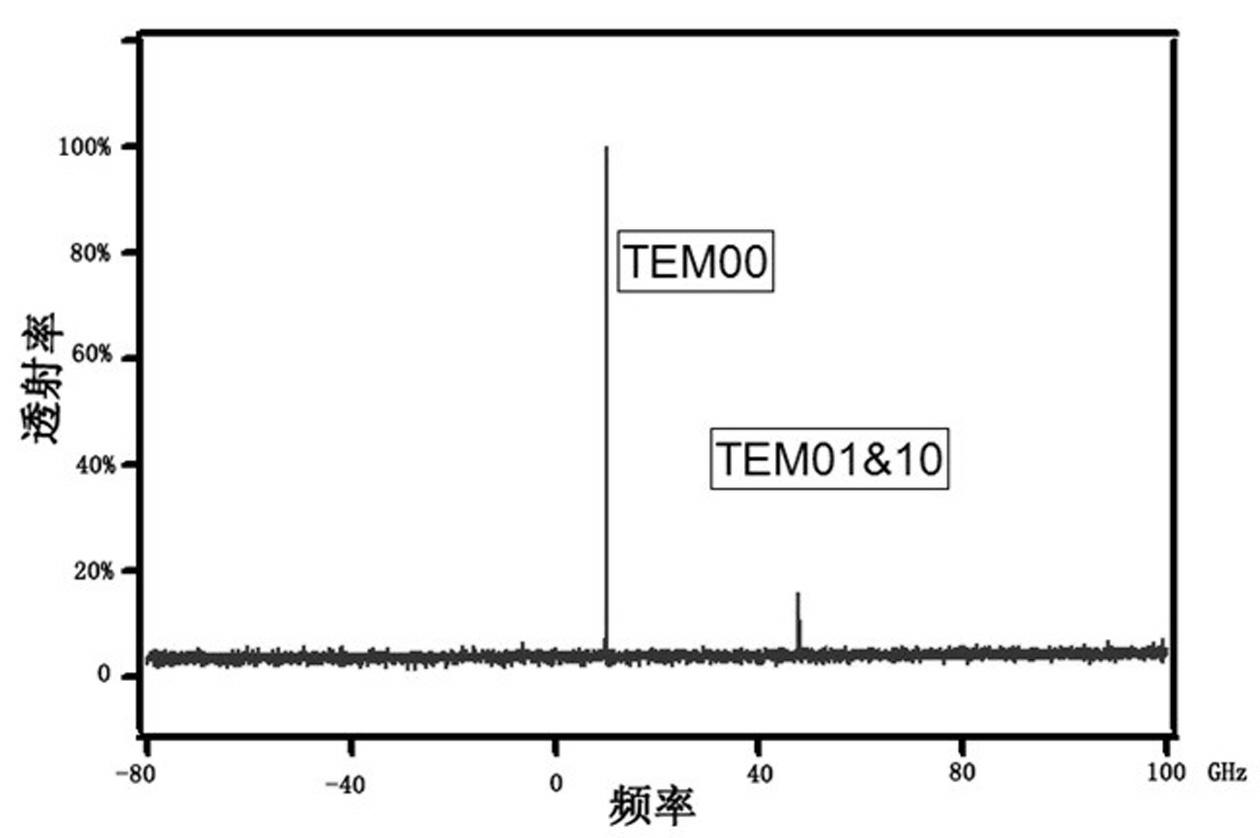

[0027] A method for manufacturing an ultra-stable ultra-high-precision micro-optical cavity includes the following steps:

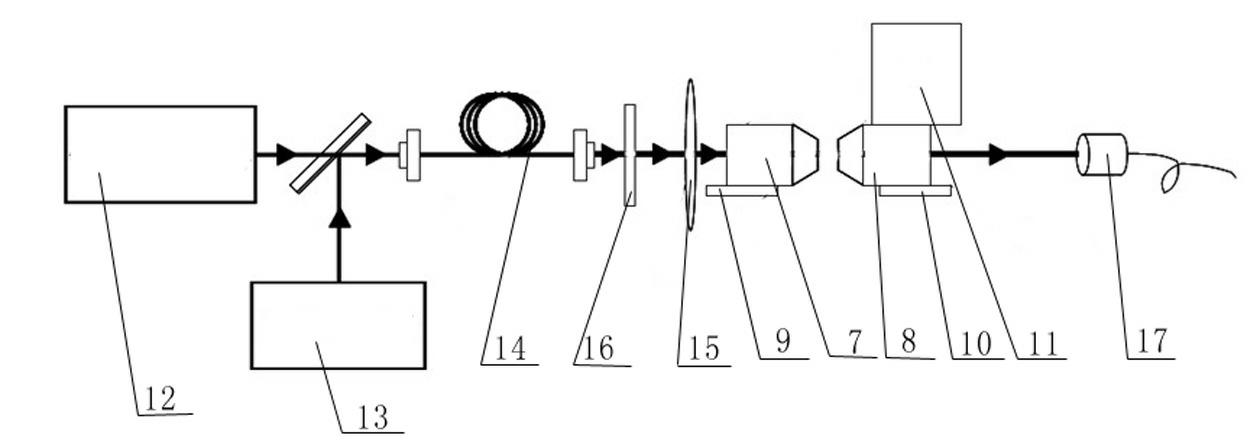

[0028] (1) Use a biological microscope to select two pieces of the first lens 7, the second lens 8, and the first lens 7, the second lens 8 with intact film, no stains, no scratches, no pits, and reflectance greater than 99.999%. The end of the reflecting surface is tapered; the dust on the surface of the first lens 7 and the second lens 8 is removed;

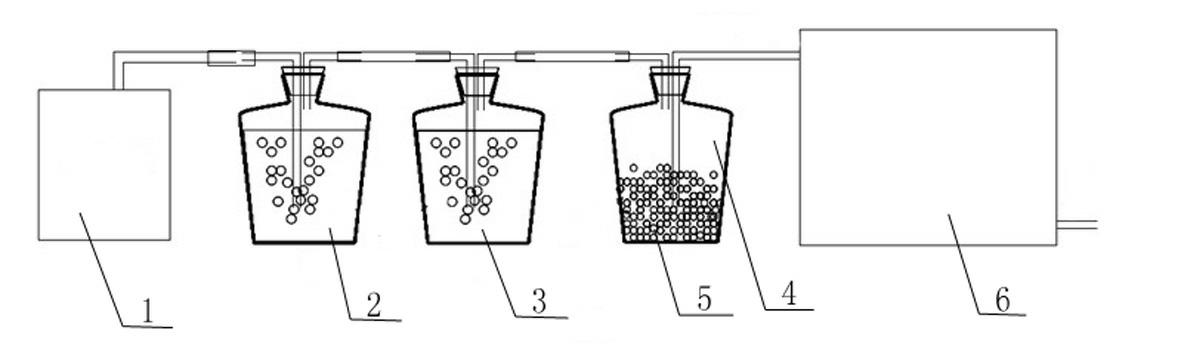

[0029] (2) Construct an air purification device for making a micro-optical cavity. The air purification device includes an air pump 1, a first sealed jar 2, a second sealed jar 3, and a third sealed jar in sequence 4; The first sealed jar 2 and the second sealed jar 3 are filled with water, and the third sealed jar is filled with desiccant 5; the third sealed jar 4 is connected to the closed operating space 6 and is airtight The operation space 6 has an air outlet;

[0030] (3) In a closed operating space 6, us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com