Production line for date palm

A production line and date palm technology, applied in food processing, application, food preparation, etc., can solve problems such as environmental pollution, difficulty in meeting hygienic standards, and low production efficiency, so as to reduce production costs, avoid participation in processing, and high product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

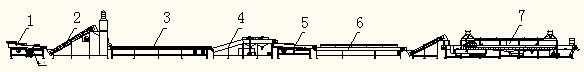

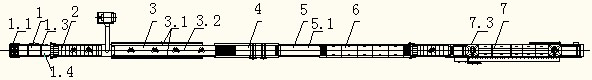

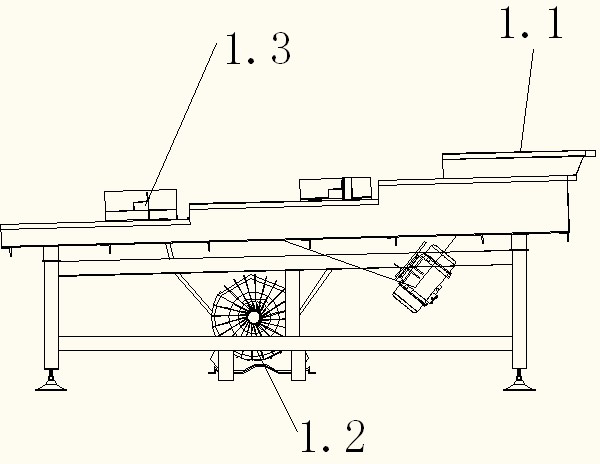

[0018] Accompanying drawing is a kind of specific embodiment of the present invention.

[0019] The date palm production line of the present invention comprises a vibrating screen 1 for breaking up raw materials and screening dates, an elevating winnowing machine 2 for removing miscellaneous leaves and granular impurities, and a selection and transportation for date palms Machine 3. Roller washing machine for dates cleaning 4. Vibration draining machine for dates drainage 5. Ultraviolet sterilizer for dates sterilization 6 and hot nest drying for dates drying machine7.

[0020] There is a dates conveying channel between the vibrating screen 1 and the lifting winnowing machine 2, through which the dates can enter the lifting winnowing machine 2 by the vibrating screen 1. There is a date palm conveying channel between the described lifting winnowing machine 2 and the described selection conveyor 3, and the date palms can enter the picking conveyor 3 by the lifting winnowing mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com