Method for reducing content of nitrites in pickles and application

A nitrite and pickle technology, which is applied in the application, climate change adaptation, food preparation and other directions, can solve the problems of reducing nitrite content, shortening the fermentation period, affecting the quality of pickles, etc., achieving simple process, shortening fermentation period, fermentation Good product quality and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

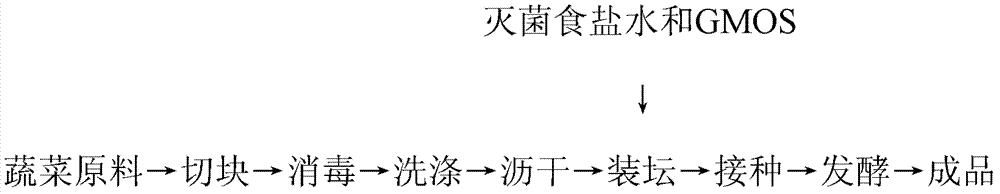

[0028] To prepare pickles, process such as figure 1 Shown:

[0029] (1) Preparation of GMOS solution: using guar gum as raw material, galactomannan oligosaccharides (GMOS) were prepared by enzymatic method with β-mannanase. The reaction conditions are as follows: the concentration of guar gum is 0.5% by mass, the amount of β-mannanase is 15 IU / g, pH 6.0, temperature 45° C., and reaction for 8 hours. Under these conditions, the enzymatic hydrolysis rate was 23.7%, and the average degree of polymerization of oligosaccharides was 5.47. Put the enzymatic hydrolysis product in a boiling water bath for 30 minutes to obtain a GMOS solution.

[0030] (2) Preparation of Lactobacillus plantarum cells: first prepare MRS liquid medium, formula: peptone 10g, beef extract 10g, yeast extract 5g, K 2 HPO 4 2g, diammonium citrate 2g, sodium acetate 5g, glucose 20g, Tween-801ml, MgSO 4 ·7H 2 O 0.58g, MnSO 4 4H 2 O 0.15g, agar 12g, adjust pH to 6.4, distilled water to 1000ml, autoclave a...

Embodiment 2

[0036] Prepare pickles such as figure 1 Shown:

[0037] (1) Preparation of GMOS solution: using guar gum as raw material, galactomannan oligosaccharides (GMOS) were prepared by enzymatic method with β-mannanase. The reaction conditions are as follows: the concentration of guar gum is 0.5% by mass, the amount of β-mannanase is 15 IU / g, pH 6.0, temperature 45° C., and reaction for 8 hours. Under these conditions, the enzymatic hydrolysis rate was 23.7%, and the average degree of polymerization of oligosaccharides was 5.47. The product after enzymolysis was bathed in boiling water for 30 minutes to obtain a GMOS solution.

[0038](2) Preparation of Lactobacillus plantarum cells: first prepare MRS liquid medium, formula: peptone 10g, beef extract 10g, yeast extract 5g, K 2 HPO 4 2g, diammonium citrate 2g, sodium acetate 5g, glucose 20g, Tween-801ml, MgSO 4 ·7H 2 O 0.58g, MnSO 4 4H 2 O 0.15g, agar 12g, adjust the pH value to 6.4, distilled water to 1000ml, autoclave at 121°...

Embodiment 3

[0044] Prepare pickles such as figure 1 Shown:

[0045] (1) Preparation of GMOS solution: using guar gum as raw material, galactomannan oligosaccharides (GMOS) were prepared by enzymatic method with β-mannanase. The reaction conditions are as follows: the concentration of guar gum is 0.1% by mass, the amount of β-mannanase is 13 IU / g, pH 5.8, temperature 44° C., and reaction for 6 hours. Under these conditions, the enzymatic hydrolysis rate was 19.5%, and the average degree of polymerization of oligosaccharides was 5.1. The product after enzymolysis was bathed in boiling water for 20 minutes to obtain a GMOS solution.

[0046] (2) Preparation of Lactobacillus plantarum cells: first prepare MRS liquid medium, formula: peptone 10g, beef extract 10g, yeast extract 5g, K 2 HPO 4 2g, diammonium citrate 2g, sodium acetate 5g, glucose 20g, Tween-801ml, MgSO 4 ·7H 2 O 0.58g, MnSO 4 4H 2 O 0.15g, agar 12g, adjust pH to 6.4, distilled water to 1000ml, autoclave at 121°C for 20mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com