Manufacture method and device for steel wire spiral filaments

A technology of spiral wire and steel wire, which is applied in the field of mine safety material manufacturing and steel wire spiral wire preparation, can solve the problems of increased production cost, total production cost, increased sales price, and high price, and achieves a simple method that is conducive to popularization and application and device, the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

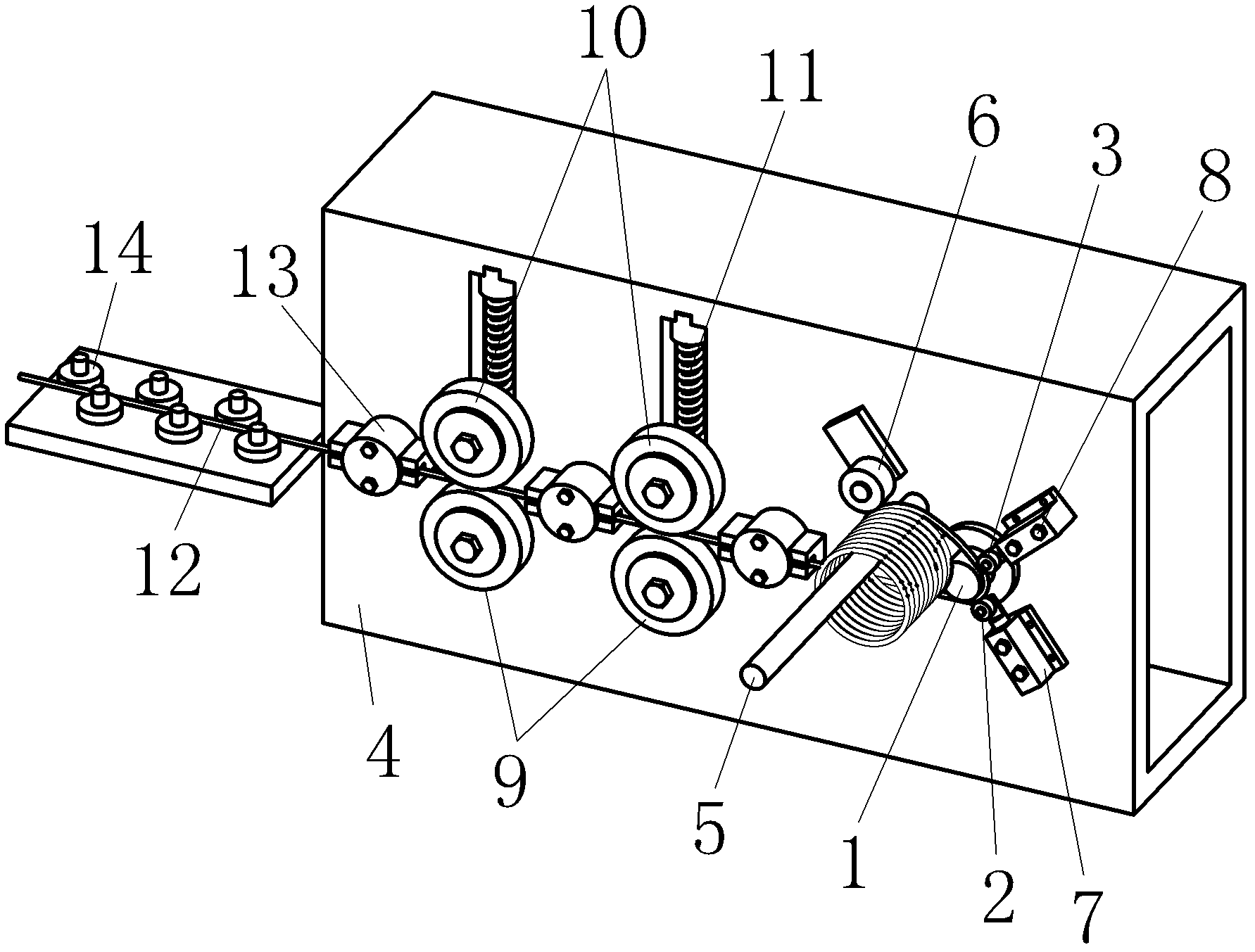

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

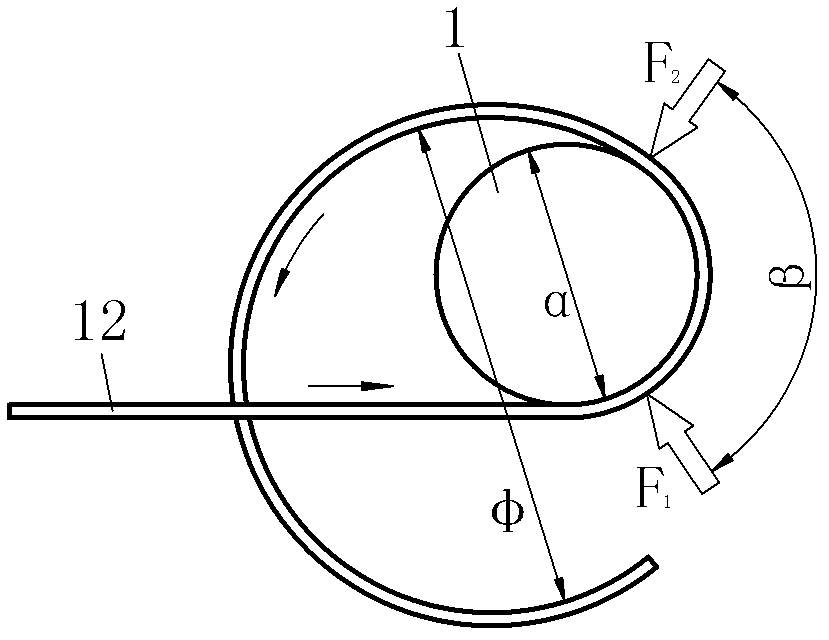

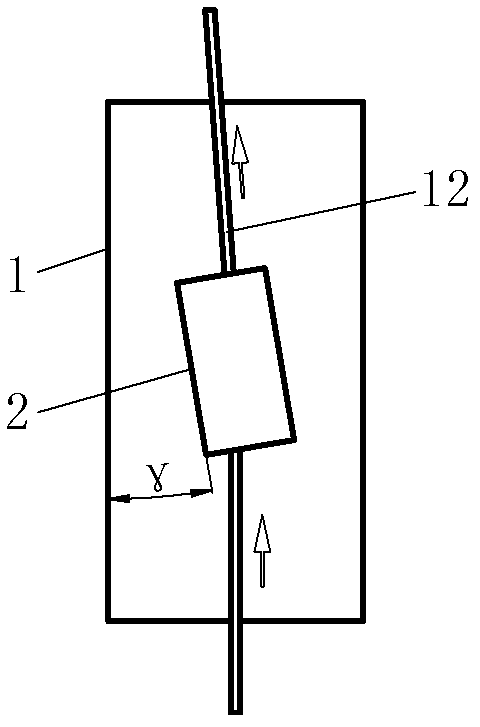

[0023] Example. A kind of preparation method of steel wire helical wire, such as figure 2 As shown, in this method, the driving roller is used as the fulcrum, the steel wire continuously passes through the arc surface of the driving roller, and the bending force F is applied to the steel wire on both sides of the driving roller 1 and F 2 , so that the steel wire produces a bend with an envelope angle of β on the arc surface of the driving roller, when the steel wire passes through the force point F 2 It cannot then spring back to its original shape, resulting in a permanent bend diameter φ that is larger than the drive roller diameter α. The permanent bending diameter φ is proportional to the driving roller diameter α, the permanent bending diameter φ and the envelope angle are β, and the bendin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com