Shifting device of double-side assembling and clamping workpiece for automatic welding of hydraulic support

A technology of automatic welding and hydraulic support, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., to reduce labor intensity, ensure welding process, and improve utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

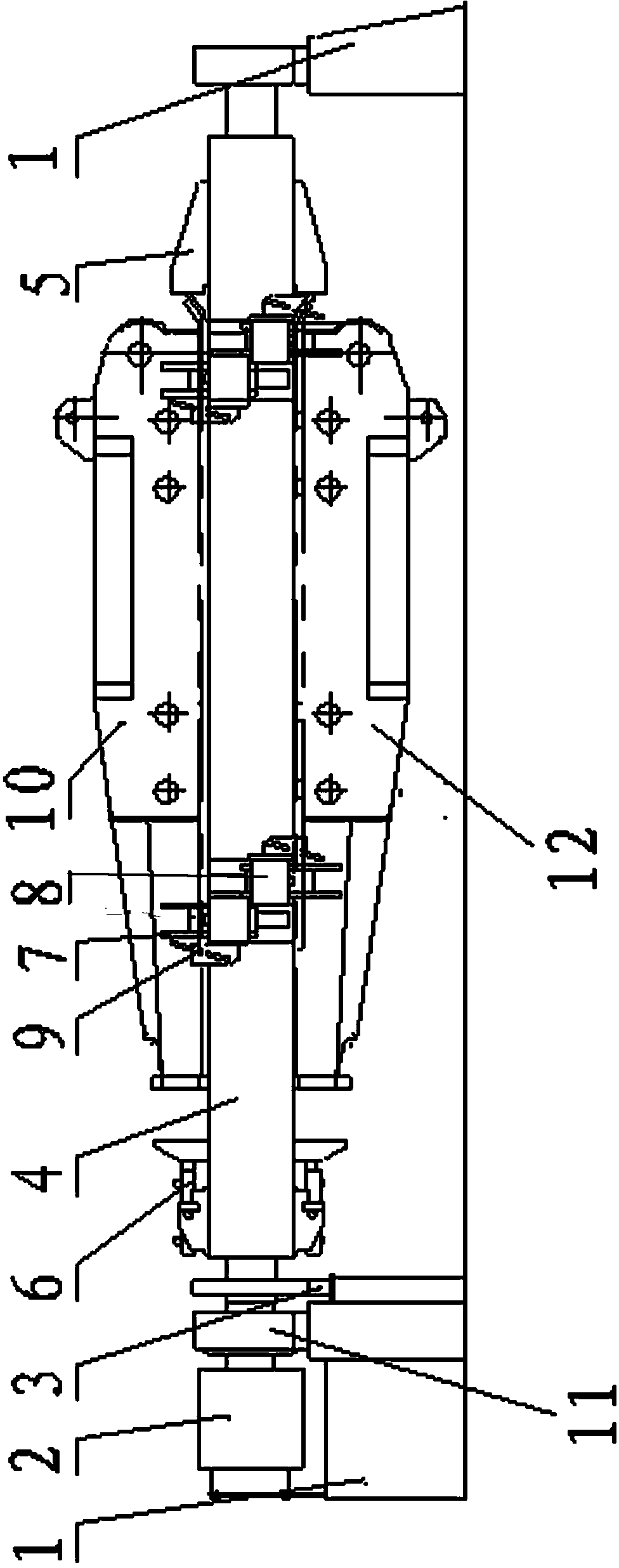

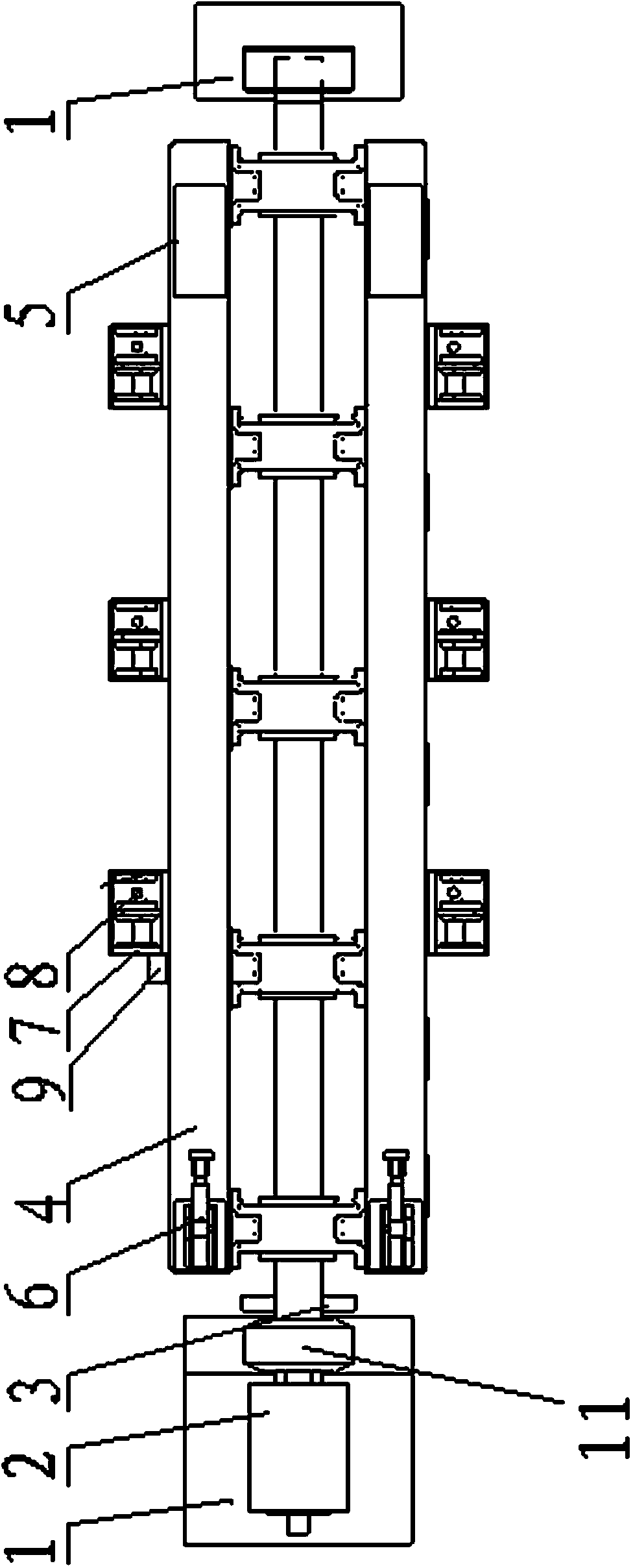

[0017] Such as figure 1 , 2 As shown in the figure, a displacement device for double-sided clamping workpieces used for automatic welding of hydraulic supports, the structure includes two supports 1 at both ends, and a turning platform 4 is inserted between the two supports 1, one of which supports The seat is provided with an overturning drive mechanism 2, and the overturning drive mechanism 2 is connected with the rotating shaft of the overturning platform 4 through the speed reduction mechanism 11, and the rotating shaft passes through the overturning positioning mechanism 3, and fixed positioning seats 5, 5, Lateral positioning mechanism 6, clamping mechanism 8, insurance mechanism 9.

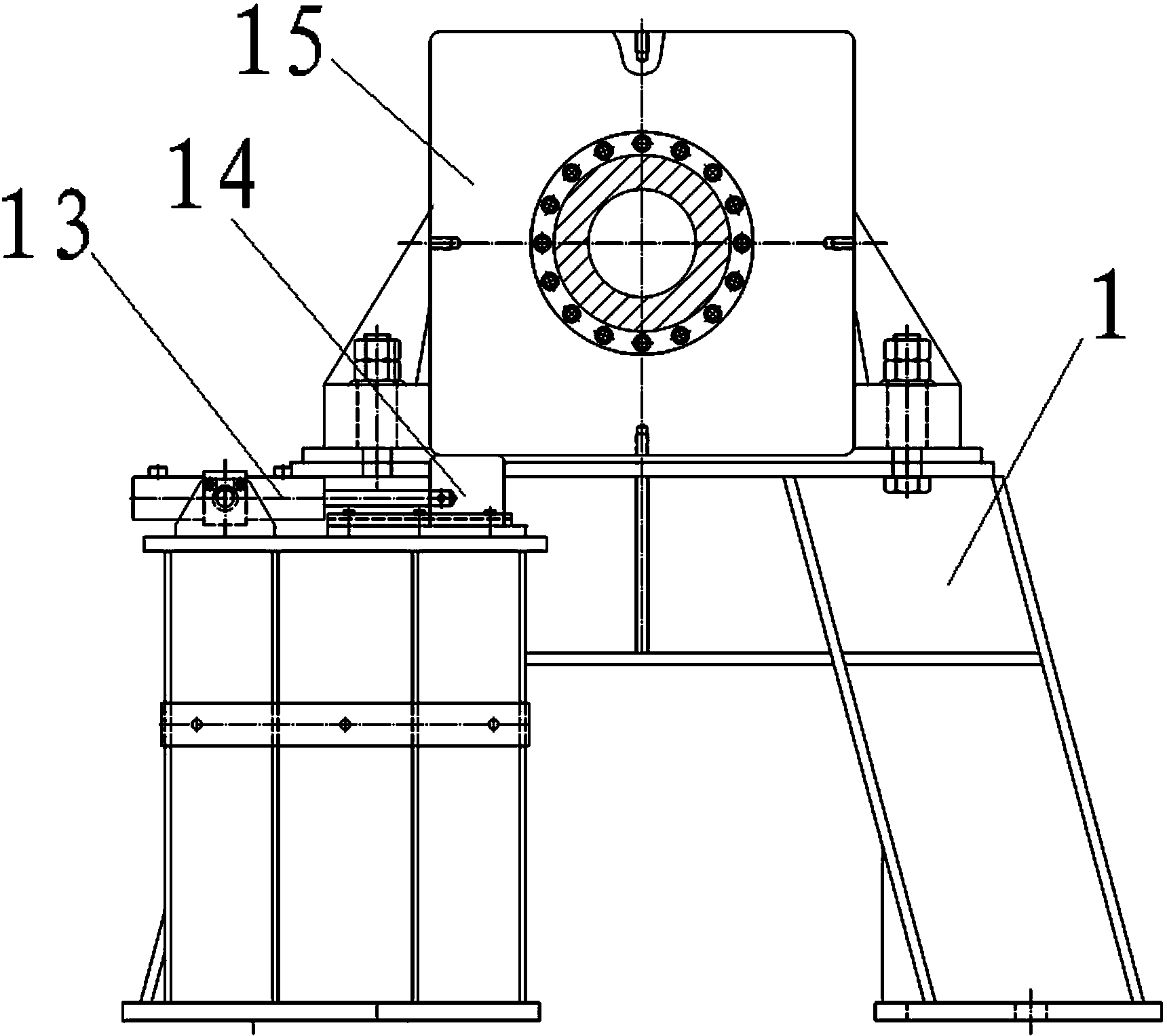

[0018] Such as image 3 As shown, the structure of the flipping positioning mechanism 3 includes a square positioning piece. The positioning piece 15 is fixed to the rotating shaft of the turning platform.

[0019] The first block 14 is driven by the thrust device 13, so that the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com