Machine for planning woods in constant length, width and thickness

A slicing machine, wood technology, applied in the direction of wood processing equipment, veneer manufacturing, manufacturing tools, etc., can solve the problems of uneven surface of oriented strand board, different sizes, lengths, waste of raw materials, etc., to achieve smooth surface, inside and outside Consistent structure and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

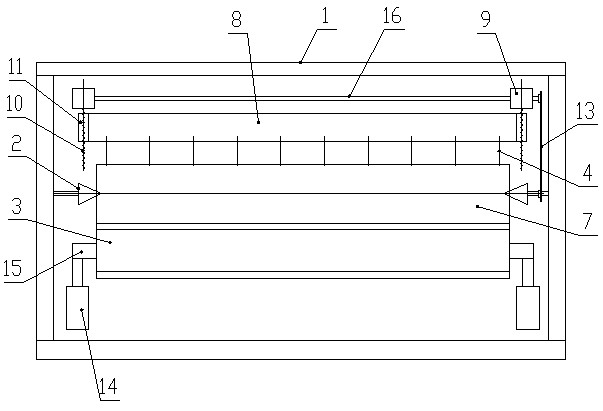

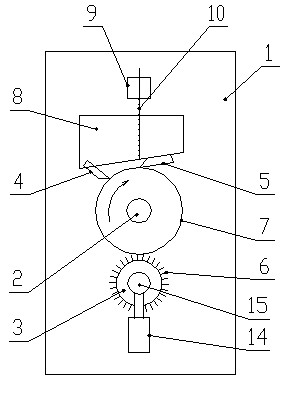

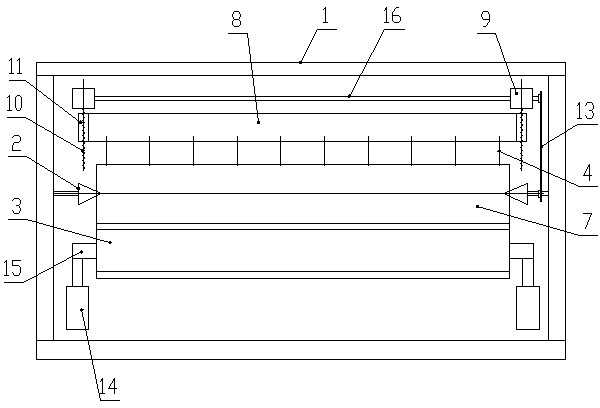

[0013] like figure 1 and figure 2 As shown, the fixed-length, wide-thickness wood planer of the present invention includes a frame 1, and the frame 1 is provided with a wood clamping device 2, a knife seat 8 and a knife roller 3, and the knife seat 8 is provided with a fixed-length cutter 4 and the fixed-thickness cutter 5, a fixed-length and fixed-thickness adjusting device is driven and connected on the knife base 8, the wood clamping device 2 and the cutter roller 3 are rotatably connected to the frame 1, and the rotation center line of the wood clamping device 2 and the cutter The rotation center line of the roller 3 is parallel, and several fixed-width cutting knives 6 are evenly arranged on the surface of the knife roller 3 in the axial direction. The distance between two adjacent fixed-width cutting knives 6 is equal. The fixed-length cutter 4 is arranged on the side of the wood clamping device 2 and is perpendicular to the rotation center line of the wood clamping de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com