Activated carbon capable of deeply purifying drinking water and preparation method for activated carbon

A technology of activated carbon and water purification, applied in chemical instruments and methods, other chemical processes, adsorption water/sewage treatment, etc., can solve problems such as ineffective utilization of coal tar resources, complex production process, high production cost, etc. High, large adsorption capacity, good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

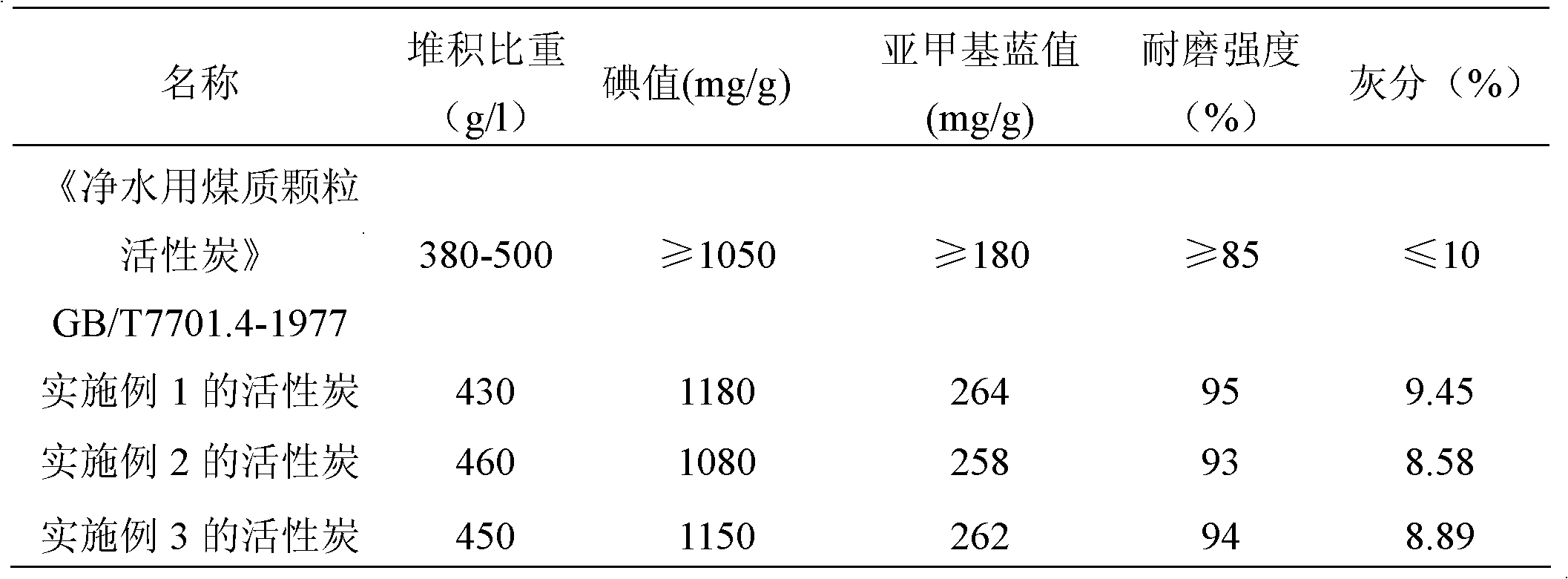

Examples

Embodiment 1

[0029] Embodiment 1, the preparation of activated carbon for deep water purification

[0030] (1) Crushing and pulverizing: crush the weakly caking coal into a particle size of 5-7mm, and then pulverize through a ball mill to obtain powder, and the particle size after pulverization reaches more than 99% and passes through 200 mesh;

[0031] (2) Briquetting molding: mix the powder obtained above with NaOH and KCl evenly, wherein the mass-number ratio of NaOH, KCl and weakly caking coal is 0.1:0.05:100, and use double-roller high-pressure molding equipment Carry out dry briquetting molding to mixed powder under 20MPa pressure to obtain briquette;

[0032] (3) Carbonization: Carbonize the briquette material with the qualified particle size obtained above in a multi-chamber furnace to obtain carbonized material. The final temperature of carbonization is 550° C., the carbonization time is 5 hours, and the heating rate is controlled to be 4° C. / min;

[0033] (4) Activation: Activat...

Embodiment 2

[0035] Embodiment 2, the preparation of activated carbon for deep water purification

[0036] (1) Crushing and pulverizing: crush the weak caking coal into a particle size of 5-7mm, and then pulverize through a ball mill to obtain powder, and the particle size after pulverization reaches more than 99% and passes through 200 mesh;

[0037] (2) Briquette molding: mix the powder obtained above with NaOH and KNO 3 Evenly mixed mixed powder, in which NaOH, and KNO 3 The mass / number ratio of the weakly caking coal is 0.05:0.05:100, and the mixed powder is dry-pressed into a briquette under a pressure of 30 MPa using a double-roller high-pressure forming device to obtain a briquette;

[0038] (3) Carbonization: Carbonize the briquette material with the qualified particle size obtained above in a multi-chamber furnace to obtain a carbonized material. The final temperature of carbonization is 650° C., the carbonization time is 2 hours, and the heating rate is controlled to be 10° C. / m...

Embodiment 3

[0041] Embodiment 3, the preparation of activated carbon for deep water purification

[0042] (1) Crushing and pulverizing: crush the weak caking coal into a particle size of 5-7mm, and then pulverize through a ball mill to obtain powder, and the particle size after pulverization reaches more than 99% and passes through 200 mesh;

[0043] (2) Briquette forming: mix the powder obtained above with KOH and NaNO 3 Mixed homogeneous mixed powder, in which KOH and NaNO 3 The mass / number ratio of the weakly caking coal is 1.0:0.05:100, and the mixed powder is dry-pressed into a briquette under a pressure of 50 MPa using a double-roller high-pressure forming equipment to obtain a briquette;

[0044] (3) Carbonization: Carbonize the above-mentioned briquettes with qualified particle sizes in a multi-chamber furnace to obtain carbonized materials. The final temperature of carbonization is 600° C., the carbonization time is 3 hours, and the heating rate is controlled to be 6° C. / min;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com