Method for producing light calcium carbonate slurry and light calcium carbonate paste

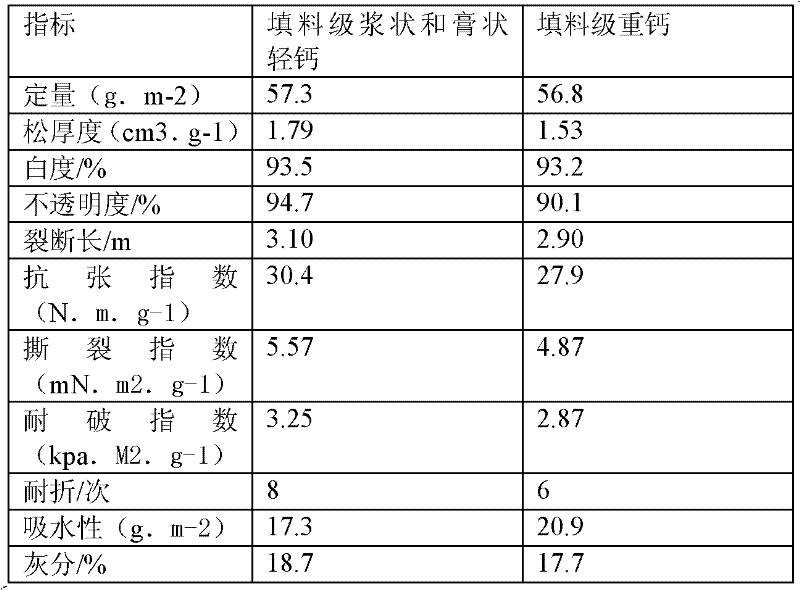

A light calcium carbonate, production method technology, applied in the direction of calcium carbonate/strontium/barium, products, reagents, etc., can solve the problems of poor product quality, low sedimentation volume, complex process, etc., and achieve high output rate, whiteness High and high whiteness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0014] Embodiment: the production method of this slurry and pasty light calcium carbonate, comprises the following steps:

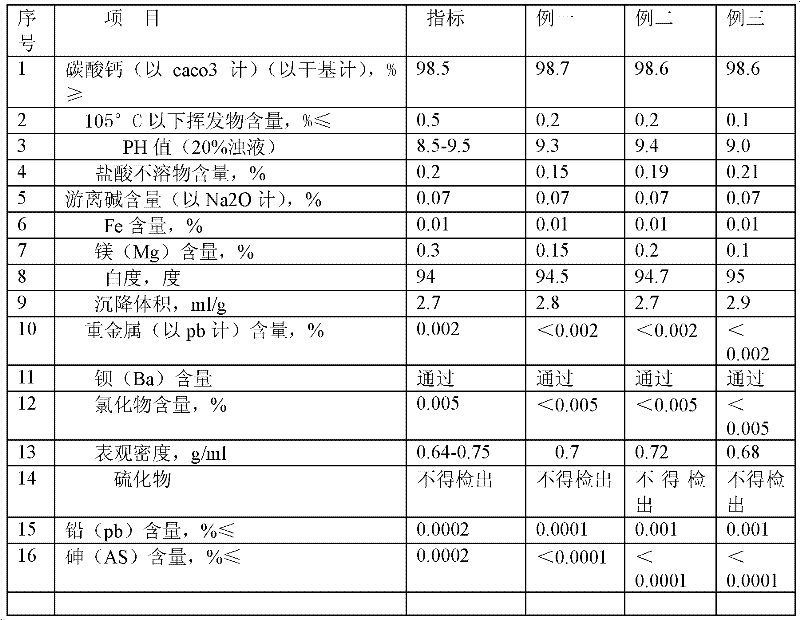

[0015] 1) Water treated with a filter is hydrated with lime CaO at a volume ratio of 7:1 at 40°C to generate a Ca(oh)2 slurry. The lime is obtained by calcining limestone at 1000-1100°C Among them, the limestone is made of dense limestone with high purity, heavy metals and impurities, and the specific indicators are as follows: purity ≥ 99.5%, heavy metal ≤ 20ppm, iron content ≤ 80ppm, lead content ≤ 2ppm, arsenic content ≤ 2ppm, magnesium Content≤0.3%.

[0016] 2) The Ca(oh)2 slurry passes through sieves with different meshes three times from small to large, namely 125 mesh, 200 mesh and 320 mesh respectively, to remove impurities in the Ca(oh)2 slurry and obtain uniform particle size and high purity It is a raw slurry, through a hydrocyclone, to further remove impurities, including heavy metals such as non-metallic silicon, lead, etc., and the Baume de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap