Sound isolation and noise reduction method for washing machine

A technology for washing machines and sound insulation coatings, which can be applied to other washing machines, washing devices, textiles and paper making, etc., can solve the problems of atmospheric noise, weak market competitiveness of drum washing machines, vibration and noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

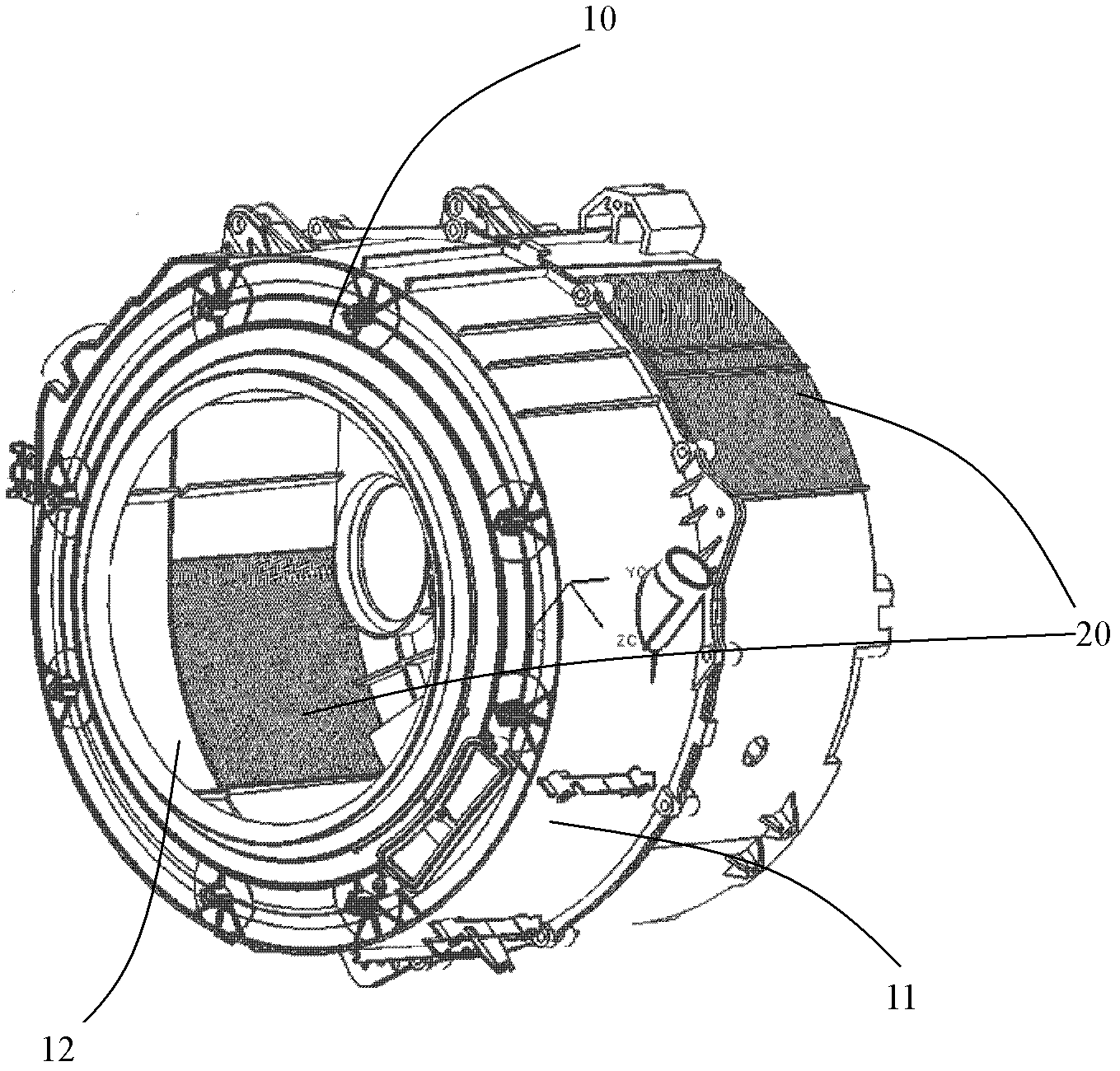

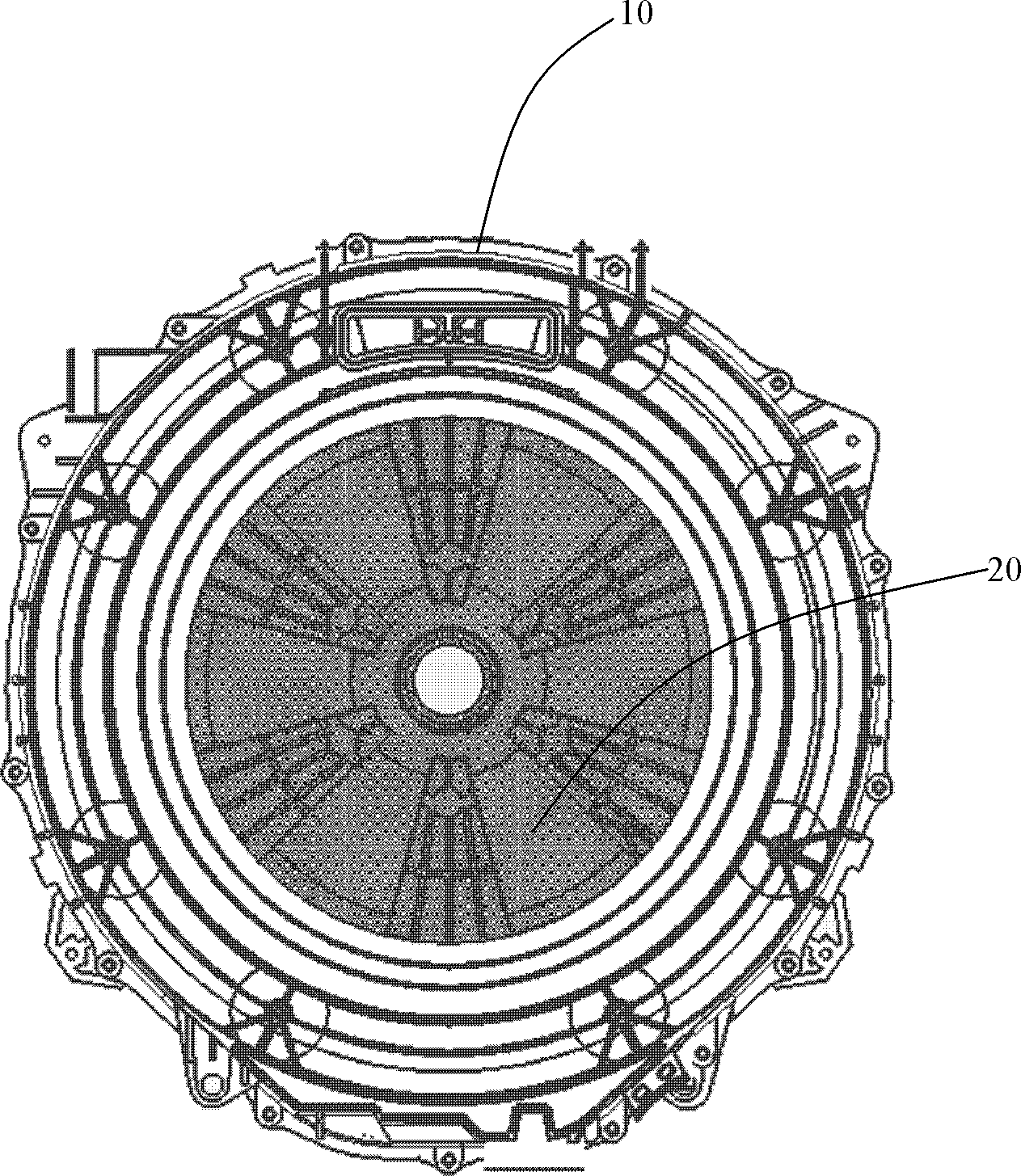

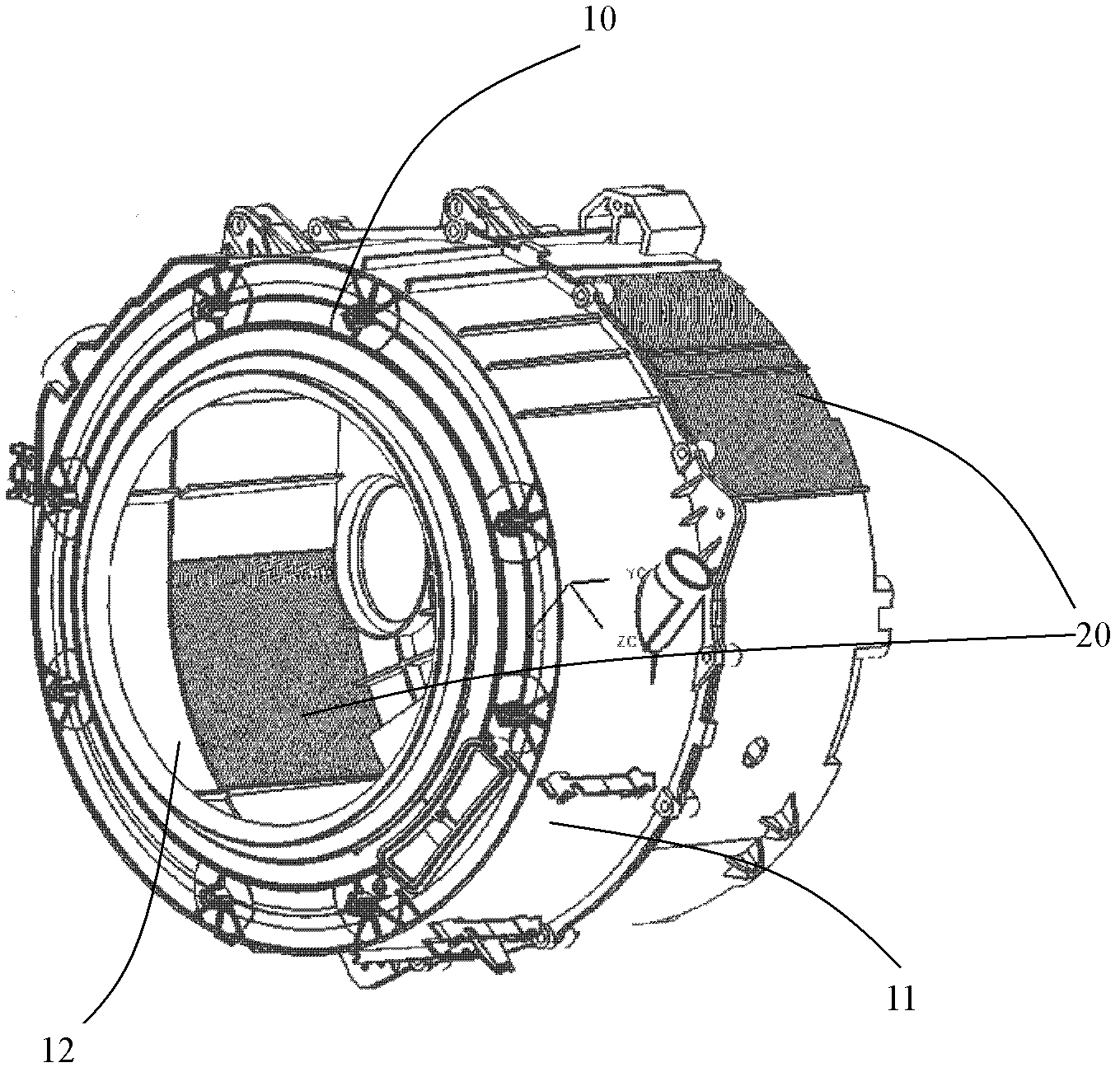

[0013] Embodiment 1: The method for sound insulation and noise reduction of a washing machine in this embodiment, puts the sound insulation coating 20 into a spray gun, and sprays directly on the outer surface 11 and inner surface 12 of the outer cylinder 10 of the washing machine, and the spraying thickness is 0.5 mm. When the drum washing machine is performing high-speed dehydration, the sound insulation coating 20 has fine particles with sound insulation effect, which can reduce the sound wave energy transmitted by the outer cylinder of the washing machine, thereby achieving the effect of sound insulation and noise reduction. Test a LG Prime Refresh WD-T12345D type drum washing machine, and conduct a comparative test with and without using the sound insulation and noise reduction method of the present invention. When the noise is 0.5 to 1 decibel, it has achieved the effect of sound insulation and noise reduction.

Embodiment 2

[0014] Embodiment 2: The sound insulation and noise reduction method of the washing machine in this embodiment, put the sound insulation coating 20 into the spray gun, and directly spray the outer surface 11 and the inner surface 12 of the outer cylinder 10 of the washing machine, and the spraying thickness is 2mm. When the drum washing machine is performing high-speed dehydration, the sound insulation coating 20 has fine particles with sound insulation effect, which can reduce the sound wave energy transmitted by the outer cylinder of the washing machine, thereby achieving the effect of sound insulation and noise reduction. Test a LG Prime Refresh WD-T12345D model drum washing machine, and conduct a comparative test with and without adopting the sound insulation and noise reduction method of the present invention. When the noise is 0.5 to 2 decibels, it achieves the effect of sound insulation and noise reduction.

Embodiment 3

[0015] Embodiment 3: The sound insulation and noise reduction method of the washing machine in this embodiment, the sound insulation coating 20 is put into the spray gun, and the outer surface 11 and the inner surface 12 of the outer cylinder 10 of the washing machine are directly sprayed, and the spraying thickness is 3mm. When the drum washing machine is performing high-speed dehydration, the sound insulation coating 20 has fine particles with sound insulation effect, which can reduce the sound wave energy transmitted by the outer cylinder of the washing machine, thereby achieving the effect of sound insulation and noise reduction. Test a LG Prime Refresh WD-T12345D model drum washing machine, and conduct a comparative test with and without adopting the sound insulation and noise reduction method of the present invention. When the noise is 1.5 to 3 decibels, it has achieved the effect of sound insulation and noise reduction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com