An Optimum Structure of a High Quality Factor Thin Film Bulk Acoustic Resonator

A film bulk acoustic wave, high quality factor technology, applied in the direction of impedance network, electrical components, etc., can solve the problems of acoustic energy leakage, resonator quality factor damage, etc., achieve high Q value, excellent high quality factor, and improve quality factor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

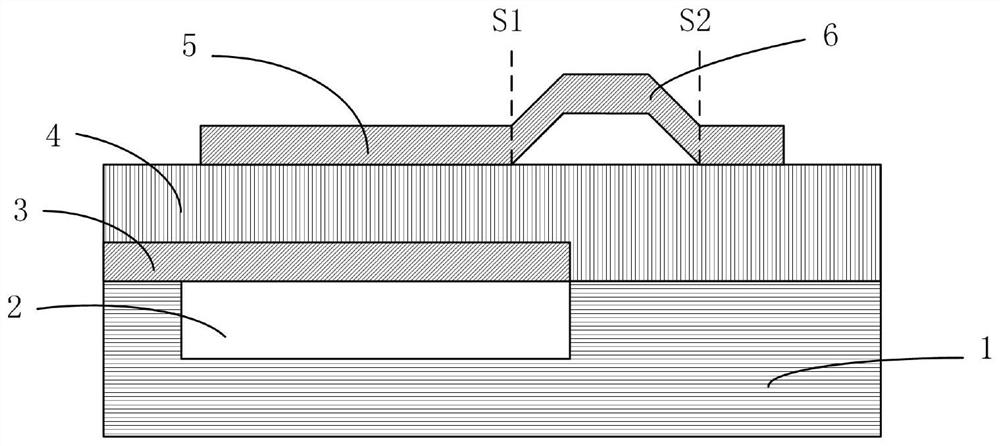

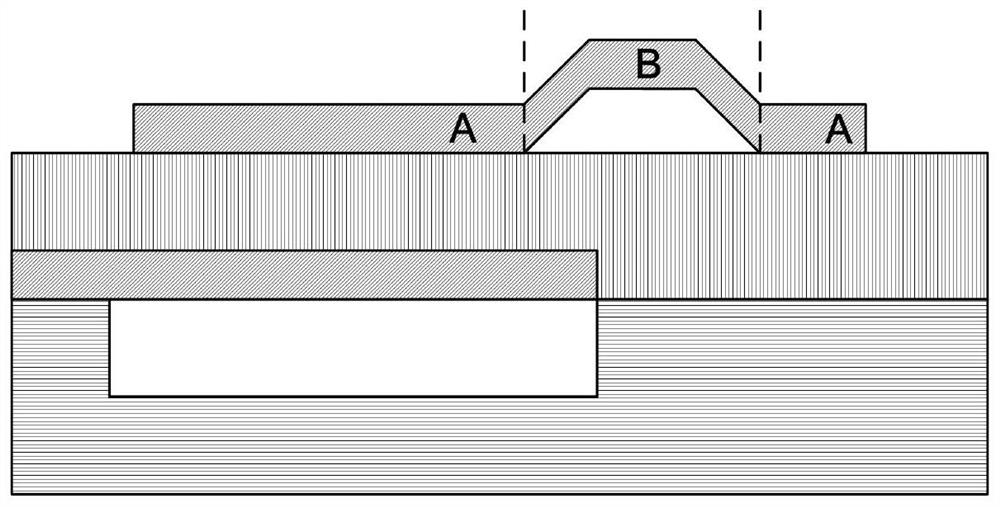

[0037] Example 1. combine Figure 2A and Figure 2B , the basic structure of a thin film bulk acoustic resonator with a high quality factor proposed by the present invention includes a substrate 1 with a groove 2 on the upper surface, a bottom electrode layer 3 above the substrate 1, a piezoelectric layer 4, a strip There is a top electrode layer 5 with an air bridge structure 6, wherein the air bridge structure 6 is provided with an acoustic rebound structure 7 that can rebound the transverse sound wave and improve the quality factor of the film bulk acoustic resonator; The boundary in one direction of the structure 6 is located inside the groove 2, and the boundary in the other direction extends beyond the boundary of the groove 2; the acoustic rebound structure 7 is in close contact with the air bridge structure 6, forming an acoustic wave in the horizontal propagation direction. Impedance mismatch interface; the material of the acoustic rebound structure 7 is a thin film...

Embodiment 2

[0038] Example 2. combine Figure 3A and Figure 3B , a preferred structure of a film bulk acoustic resonator with a high quality factor proposed by the present invention (Scheme 1). The preferred structure (Scheme 1) includes a substrate 1 with a groove 2 on the upper surface, a bottom electrode layer 3 above the substrate 1, a piezoelectric layer 4, and a top electrode layer 5 with a special-shaped air bridge structure 12. , the special-shaped air bridge structure 12 is provided with an acoustic rebound structure 7 that can rebound the transverse sound wave and improve the quality factor of the film bulk acoustic resonator; the boundary of one direction of the special-shaped air bridge structure 12 is located at the Inside the groove 2, the boundary in another direction extends beyond the boundary of the groove 2; the acoustic rebound structure 7 is in close contact with the special-shaped air bridge structure 12, forming an acoustic impedance mismatch interface in the hor...

Embodiment 3

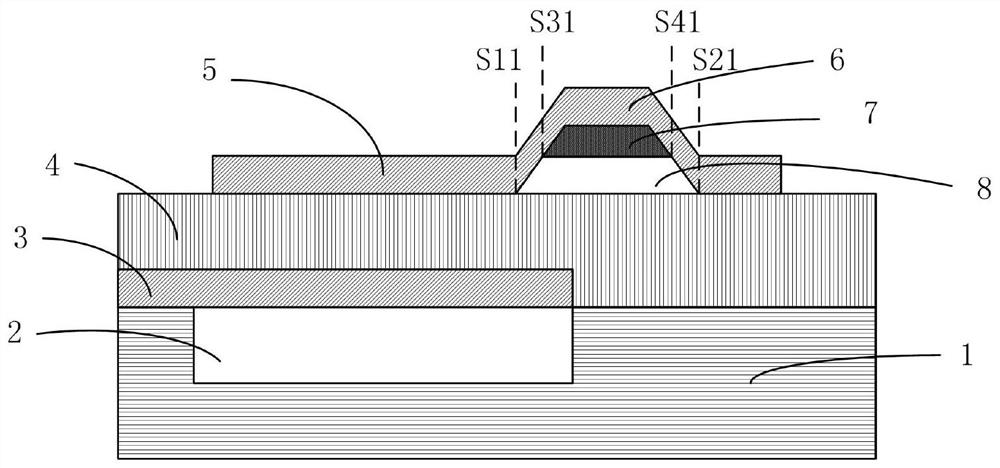

[0039] Example 3. combine Figure 4A and Figure 4B , a preferred structure of a thin-film bulk acoustic resonator with a high quality factor proposed by the present invention (Scheme 2). The preferred structure (scheme 2) includes a substrate 1 with a groove 2 on the upper surface, a bottom electrode layer 3 above the substrate 1, a piezoelectric layer 4, and a top electrode layer 5 with an air bridge structure 6, the The air bridge structure 6 is provided with an acoustic rebound structure 7 that can rebound the transverse sound wave and improve the quality factor of the film bulk acoustic resonator; the boundary of one direction of the air bridge structure 6 is located within the groove 2 , the boundary in the other direction extends beyond the boundary of the groove 2; the acoustic rebound structure 7 is in close contact with the air bridge structure 6, forming an acoustic impedance mismatch interface in the horizontal propagation direction; the material of the acoustic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com