Milling planing rotor base locating device used by pavement milling planer

A technology of milling rotor and positioning device, which is applied to roads, roads, road repair and other directions, can solve the problems of low work efficiency, high labor intensity, and small base space, and achieve convenient positioning and operation, improve connection rigidity, and work efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

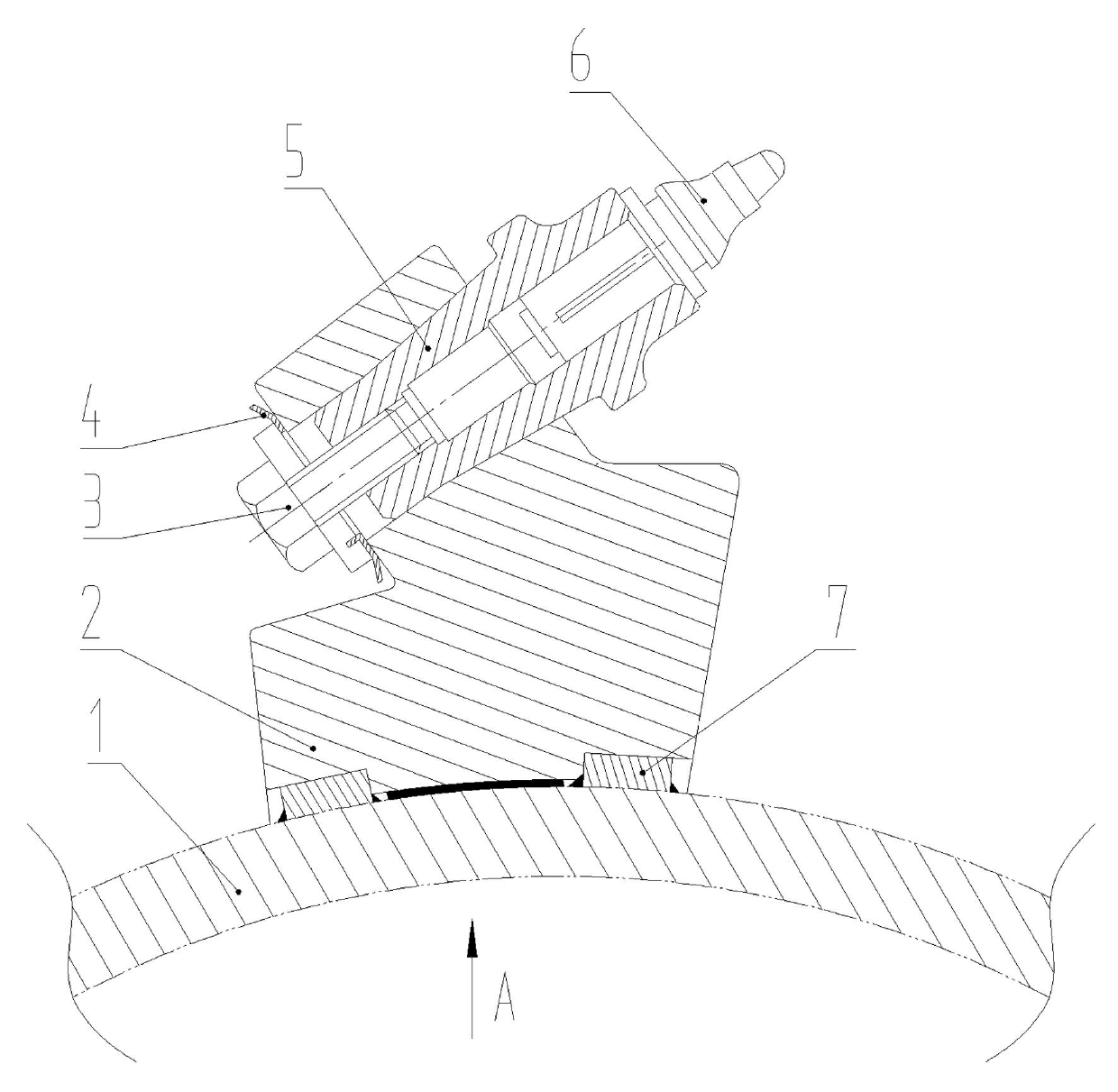

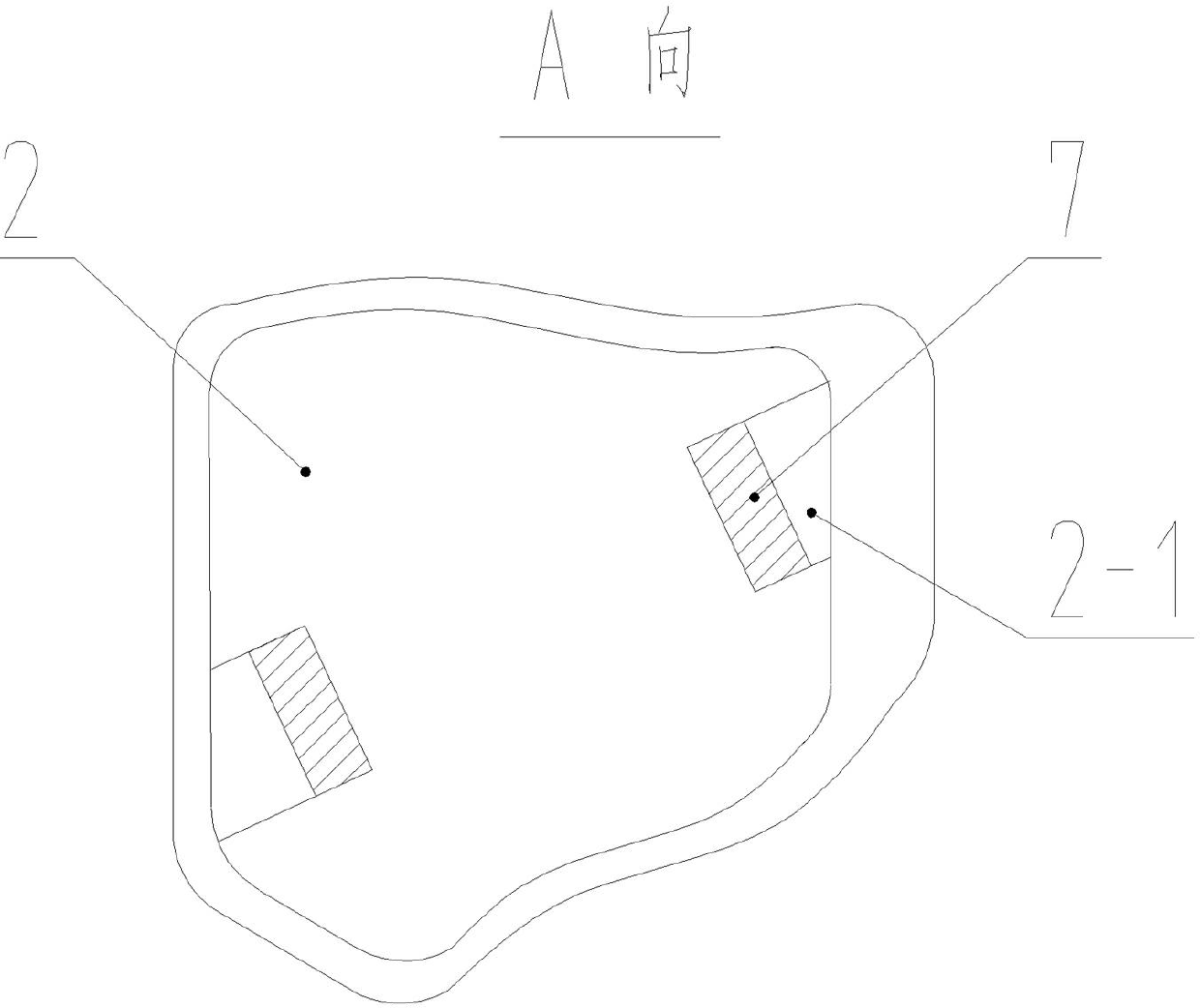

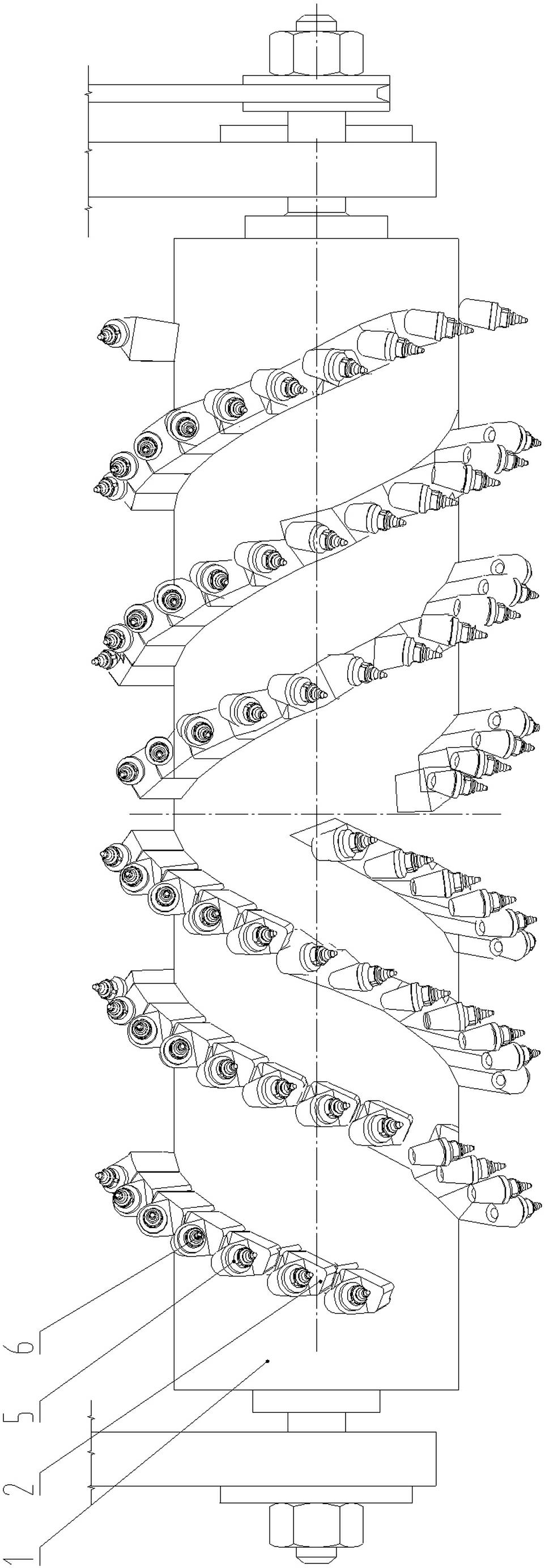

[0017] like figure 1 , figure 2 , image 3 Shown: a milling rotor base positioning device used on a road milling machine, which includes: a cylinder 1, a base 2, a cutter holder 5 and a cutter head 6. The cylinder shafts at both ends of the cylinder 1 are mounted on the milling machine frame through bearings, and the cylinder shaft is connected with the power source of the milling machine through a belt. Described cutter head 6 is installed on the cutter holder 5, and described cutter holder 5 is installed on the base 2, and described base 2 is many, and many bases 2 are divided into two groups, two groups of bases 2 are laid out as left-right symmetrical spiral lines with opposite directions of rotation, and the left and right side surfaces of multiple adjacent bases 2 are close to each other, forming two sets of auger-type spiral blade chains with opposite directions of rotation. The spiral blade surface is smooth and smooth, with low resistance. The cut materials ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com