Wide-purlin bridge floor system structure with horizontal K support

A bridge deck system and horizontal technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of reducing the bearing capacity of the lower chord, difficulty in ensuring welding quality, increasing the cross-sectional size of the beam, etc., to achieve optimal structural design, large machinery Easy maintenance, clear distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

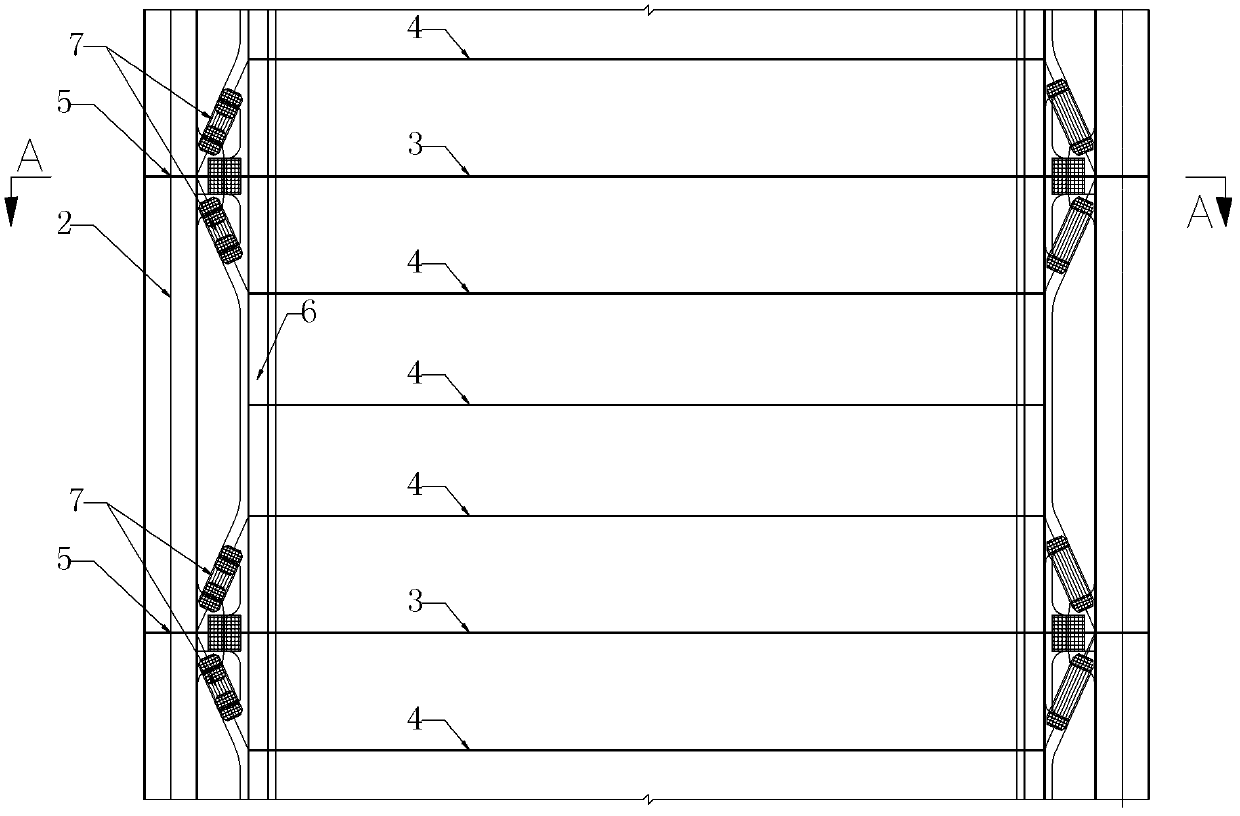

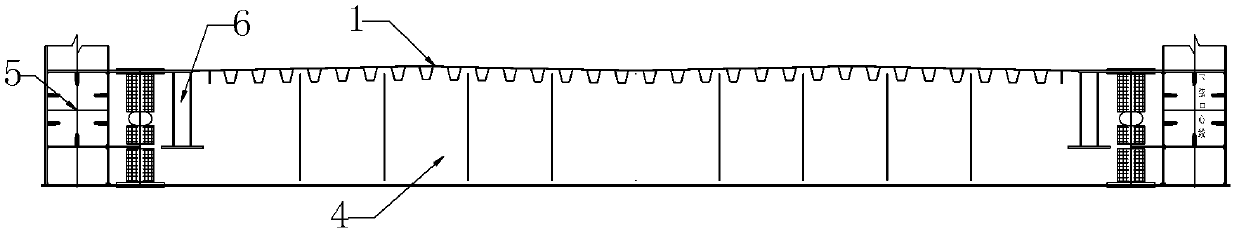

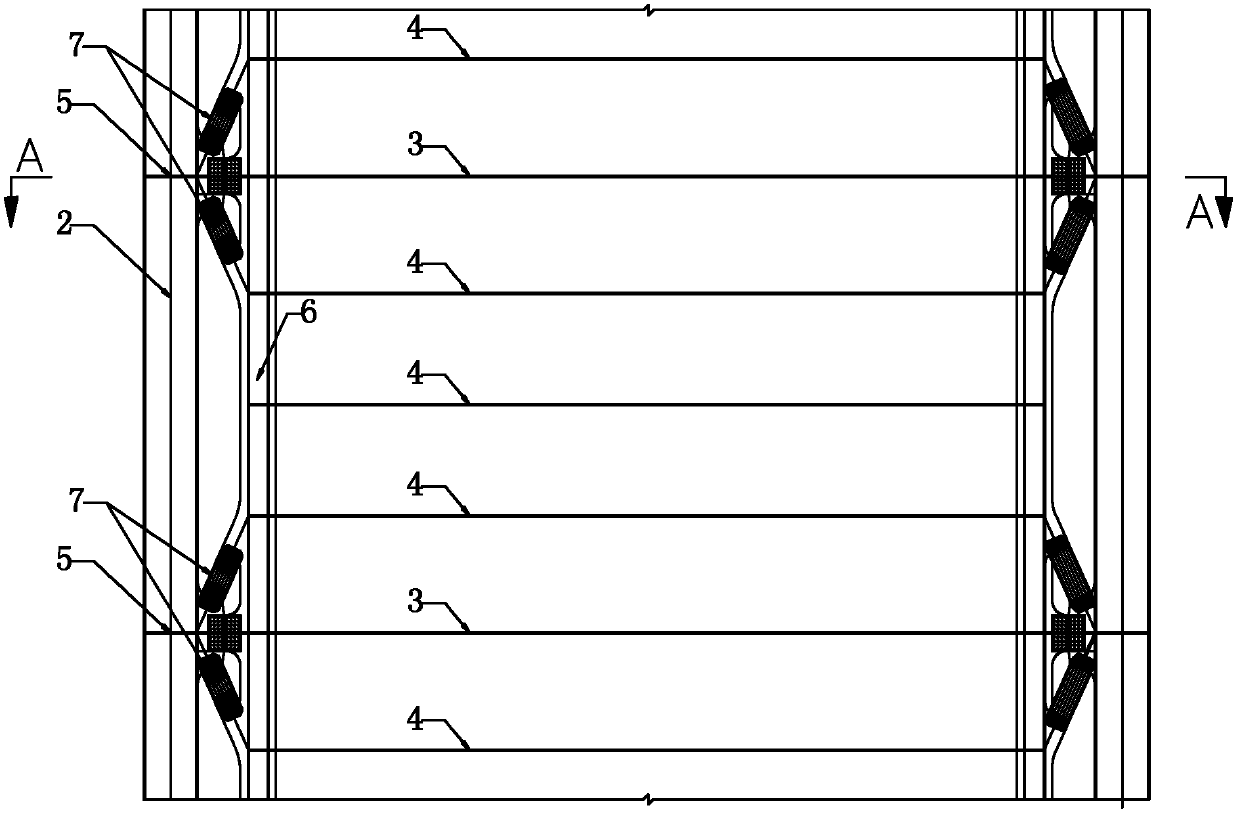

[0017] Such as figure 1 and figure 2 The wide truss bridge deck structure with horizontal K braces shown includes orthotropic steel deck 1, main truss nodes 5, main truss chords 2, longitudinal ribs arranged on the lower bottom surface of steel bridge deck 1, and set on The main beam 3 under the bridge deck 1, the steel bridge deck 1 is separated from the main truss chord 2, the two ends of each main beam 3 are connected with the main truss node 5, and there are multiple secondary beams 4 between the two main beams 3 , the two sides of the steel bridge deck 1 are provided with side longitudinal beams 6, the two ends of the side longitudinal beams 6 are connected with the main beam 3, the two ends of the secondary beam 4 are connected with the side longitudinal beams 6, the main truss nodes 5, the ends of the main beam 3 The side longitudinal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com