Impeller of hydraulic turbine

A technology of hydraulic turbines and impellers, which is applied to the supporting elements of blades, engine elements, machines/engines, etc., can solve the problems of low efficiency of hydraulic turbines, restricting popularization and application, etc., and achieves improved efficiency, reduced volume and The effect of high weight and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

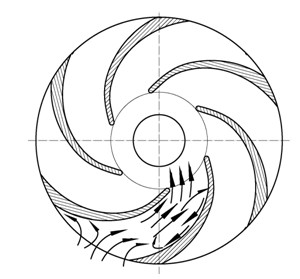

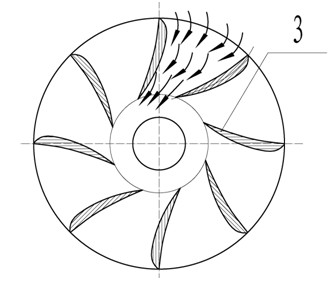

[0017] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings. The flow inside the impeller of the hydraulic turbine is approximately divided into countless (generally 1 to 5) flow surfaces. Take the blade bone line on a flow surface as an example to illustrate the structure of the blade.

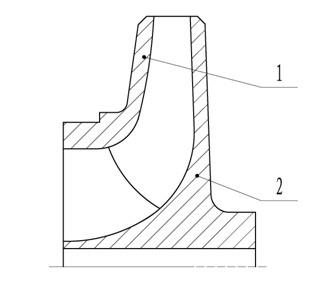

[0018] Such as figure 1 and image 3 As shown, a hydraulic turbine impeller of the present invention includes a front cover 1 , a rear cover 2 and blades 3 , and the blades 3 are fixedly connected between the front cover 1 and the rear cover 2 . The blade 3 is forward curved. The forward curved blade 3 means that the bending direction of the blade 3 is opposite to the rotation direction of the impeller. The wrapping angle of the blade 3 is between 20°-130°.

[0019] The inlet placement angle of blade 3 In this formula, β 2 Indicates the inlet placement angle of blade 3; u 2 is the peripheral speed at the impe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com