Hydraulic transformer with axial flow distribution

A hydraulic transformer and current distribution technology, applied in the field of hydraulic transformers, can solve problems such as complex structure and large volume, and achieve the effects of small volume, expanded voltage transformation range, and reduced axial size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

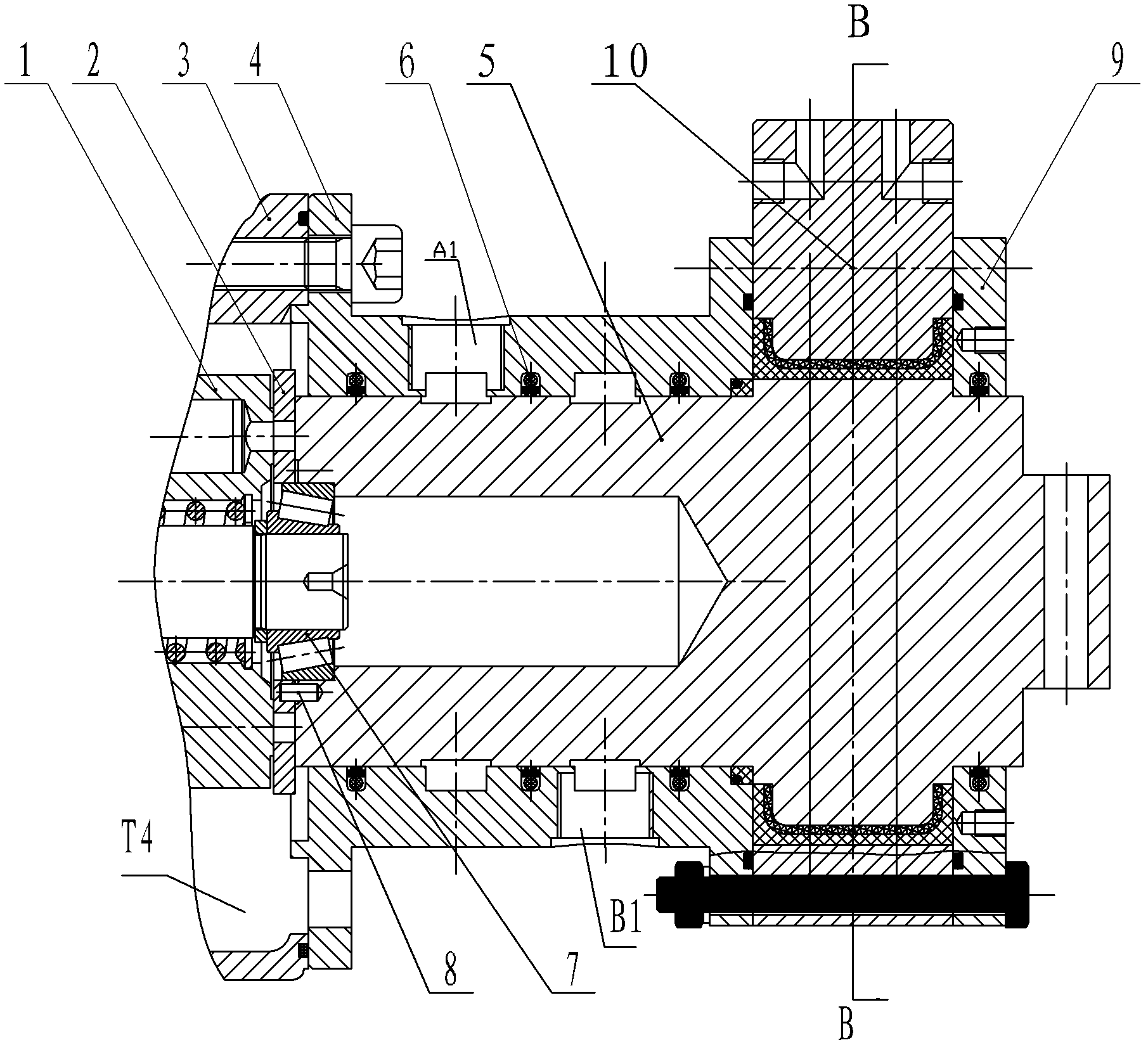

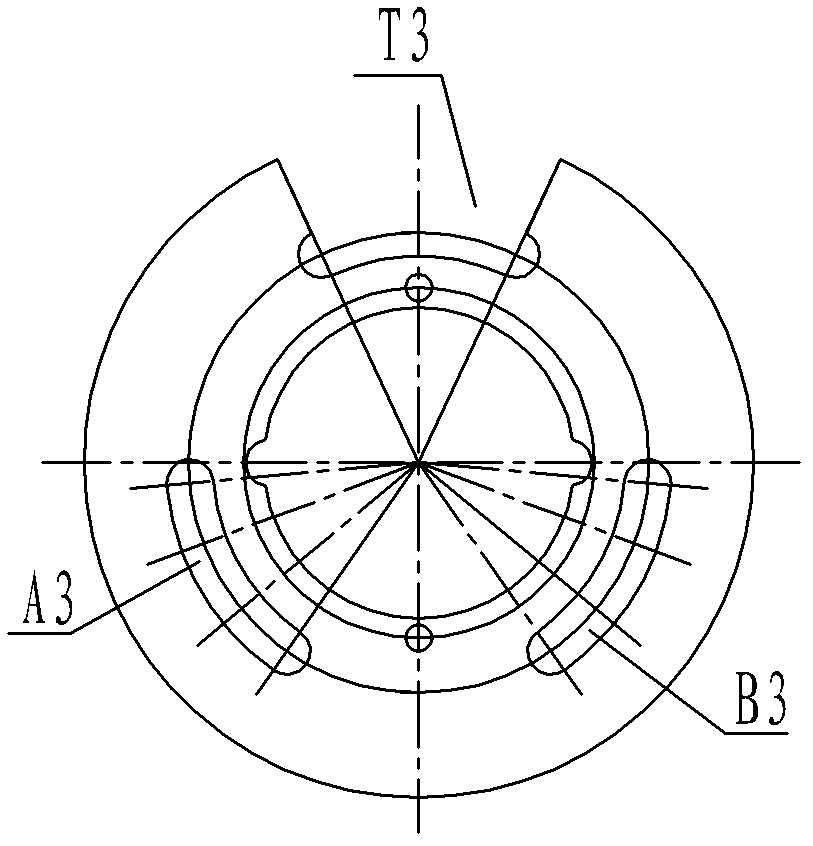

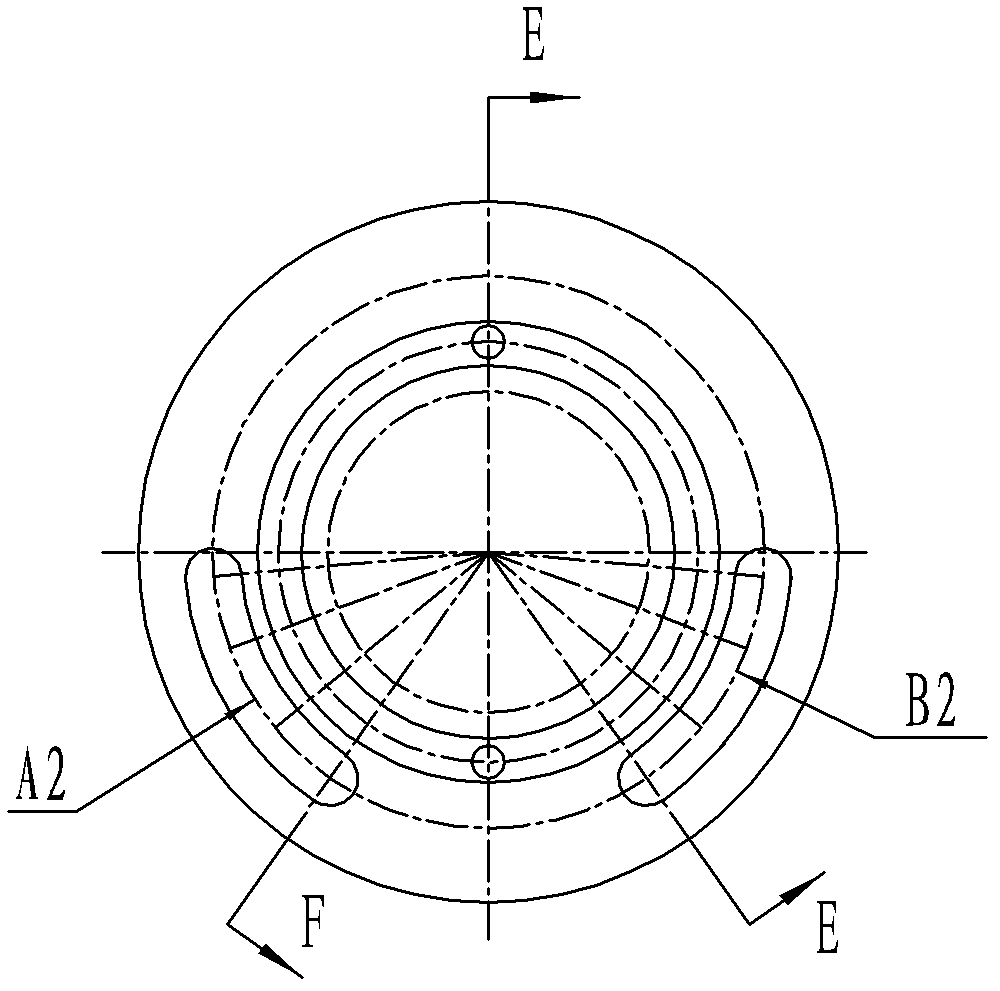

[0031] Specific implementation mode one: the following combination Figure 1 to Figure 7 Describe this embodiment. The hydraulic transformer with axial flow distribution described in this embodiment includes a cylinder body 1, which also includes a flow distribution plate 2, a pump casing 3, a flow distribution casing 4, a flow distribution main shaft 5, a bearing 7, a pin 8, and an end cover 9 and the control mechanism 10,

[0032] The cylinder body 1 is connected with the distribution plate 2 and the distribution spindle 5 in turn through the bearing 7, one end surface of the cylinder body 1 is in contact with one side end surface of the distribution plate 2, and the other end surface of the flow distribution plate 2 passes through the pin 8 and the distribution spindle 5 Fixed connection, the distribution shell 4 is set on the outer surface of the flow distribution main shaft 5, the flow distribution shell 4 and the flow distribution main shaft 5 are sealed and fixed, and t...

specific Embodiment approach 2

[0041] Specific implementation mode two: the following combination figure 1 This embodiment will be described. This embodiment is a further description of Embodiment 1. This embodiment also includes a rotating lattice ring 6 , and the distribution housing 4 and the distribution main shaft 5 are sealed by the rotating lattice ring 6 .

specific Embodiment approach 3

[0042] Specific implementation mode three: the following combination figure 1 This embodiment is described. This embodiment is a further description of Embodiment 2. There are three rotating lattice rings 6, which are respectively provided in the third annular groove h1 and the fourth annular groove on the inner ring surface of the flow distribution shell 4. h2 and the fifth annular groove h3, the third annular groove h1 is located between the distribution plate 2 and the first annular groove H1, the fourth annular groove h2 is located between the first annular groove H1 and the second annular groove H2, and the third annular groove h1 is located between the first annular groove H1 and the second annular groove H2. The five annular grooves h3 are located between the bosses of the second annular groove H2 and the distribution spindle 5 .

[0043] In this embodiment, sealing grooves are correspondingly opened on the distribution shell 4 and the distribution main shaft 5 , and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com