Instant heating water boiler and control method thereof

A control method and a water boiler technology, which are applied in the field of kitchen appliances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

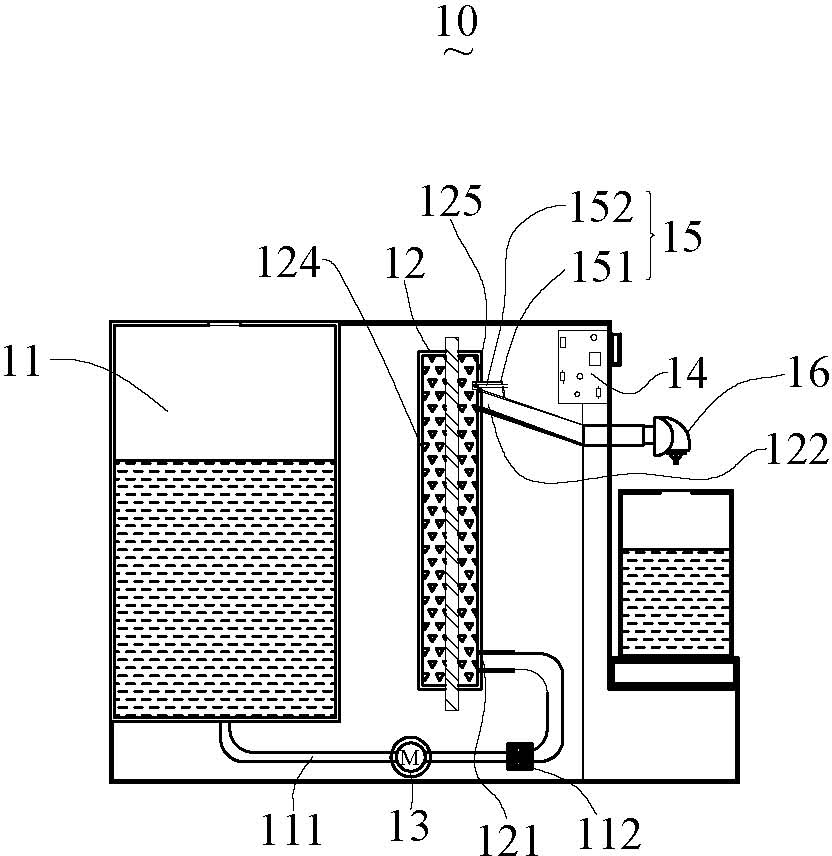

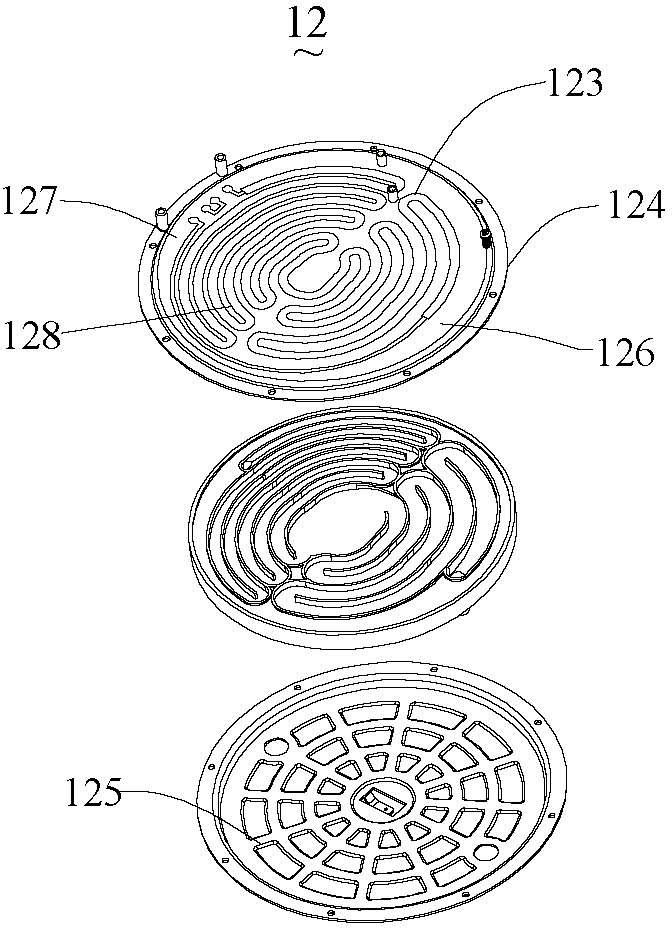

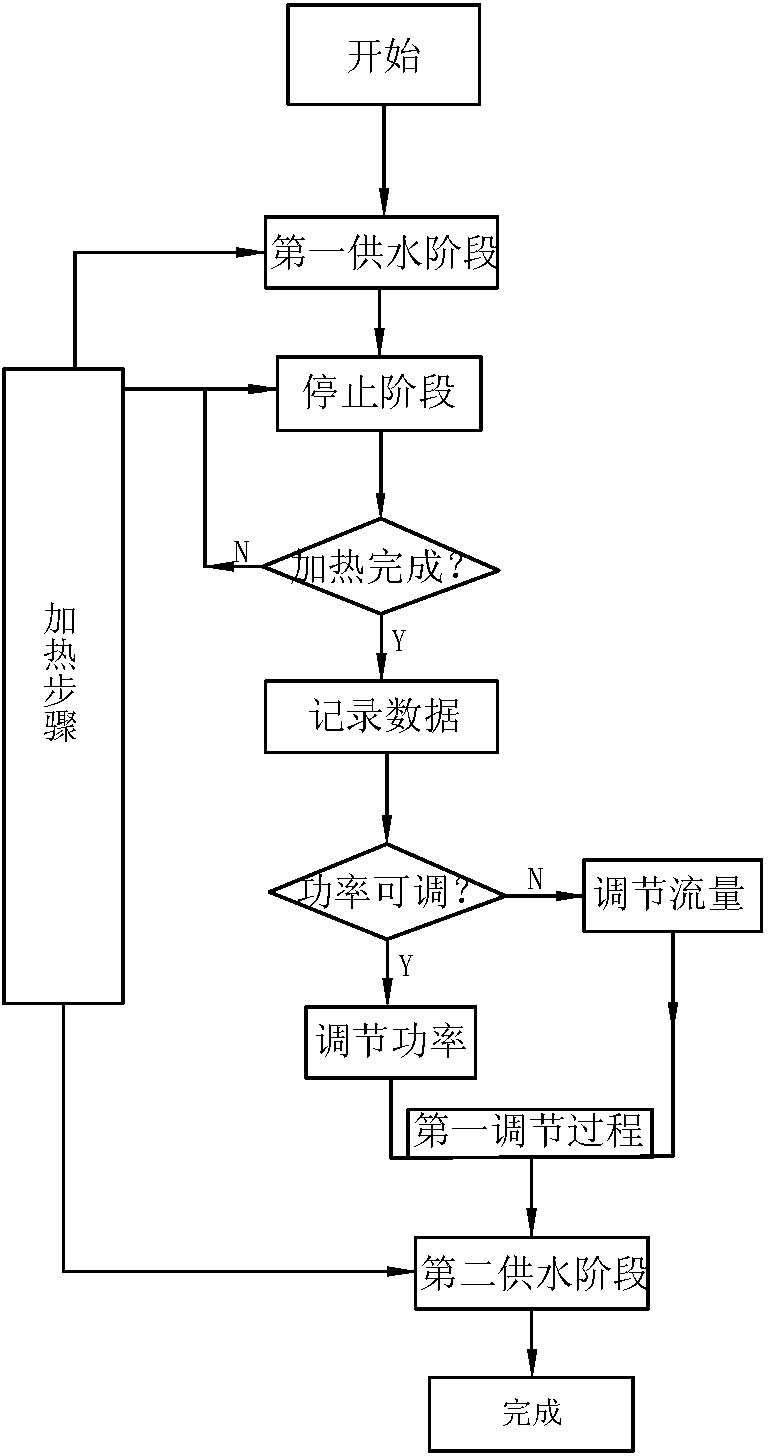

[0043] see figure 1 , the first embodiment of the instant water boiler of the present invention, the instant water boiler 10 includes a water tank 11 , a heating container 12 , a control device 14 , a water pump 13 , and a water spout 16 . The water tank 11 communicates with the heating container 12 through a water supply pipe 111 and a water pump 13 . The control device 14 is electrically connected to the heating film 123 and the water pump 13 . The heating container 12 includes a front end portion 126 connected to the water tank 11, a heating portion 128 attached with a heating film 123, and a dry-boiling detection portion 127 higher than the heating portion 128. The dry-boiling detection portion 127 is provided with a dry-boiling detection portion The sensing device 15 of water level in 127. The sensor device 15 is electrically connected to the control device 14 . The control device 14 controls the working state of the heating part 128 according to the signal of the sen...

Embodiment approach 2

[0058] see Figure 4 , the second embodiment of the instant water boiler 20 of the present invention, the difference between the instant water boiler 20 and the instant water boiler 10 is that the water pump 13 is an electromagnetic pump. Since the electromagnetic pump itself has the effect of one-way water supply and anti-backflow, the complexity of structural design is reduced.

[0059] see Figure 5 The difference between the shown second embodiment of the control method of the instant water boiler of the present invention and the first embodiment of the control method is that the control method also includes the control device 14 according to the water outlet 122 in the second water supply stage. The detection value of the temperature sensor 152 at the second adjustment process of adjusting the heating power of the heating film 123 .

[0060] In the second adjustment process, the control device 14 obtains the temperature detected by the temperature sensor 152 and compare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com