Drying crushing method for clay material and special device

A mud and material technology, applied in the direction of drying solid materials, non-progressive dryers, heating to dry solid materials, etc., can solve the problems of loud noise, easy falling off, high water content, etc., to reduce and eliminate noise and increase evaporation water , the effect of increasing the precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

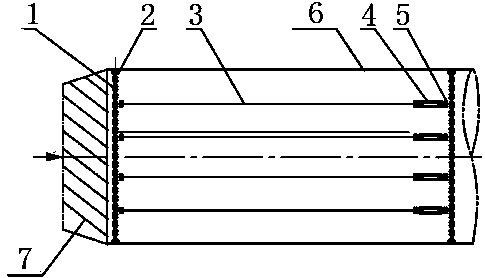

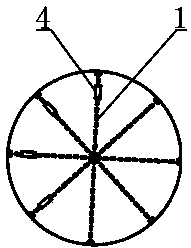

[0024] The muddy material drying and crushing method includes the following steps: ①The muddy material enters the drum dryer from the feeding end, the drum rotates, and the muddy material moves to the discharging end in the drum, and the heat medium is passed through for heat and mass exchange; ② There are several rods in the drum, and the angle between the arrangement direction of the rods and the axis of the drum is less than or equal to 45 degrees; Collision, crushing, and dried muddy materials are discharged at the discharge end of the drum.

[0025] Said rod-shaped body is parallel to the axis of the drum, its ends are arranged perpendicular to the diameter direction of the drum, and the angle between the arrangement direction of the rod-shaped body and the axis of the drum is equal to zero.

[0026] There is a lifting plate inside the dru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com