Bullet-proof and stab-resistant clothes and preparation method thereof

A bullet-proof and stab-proof clothing, composite layer technology, applied in the direction of protective equipment, chemical instruments and methods, clothing, etc., can solve the problem of inability to impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

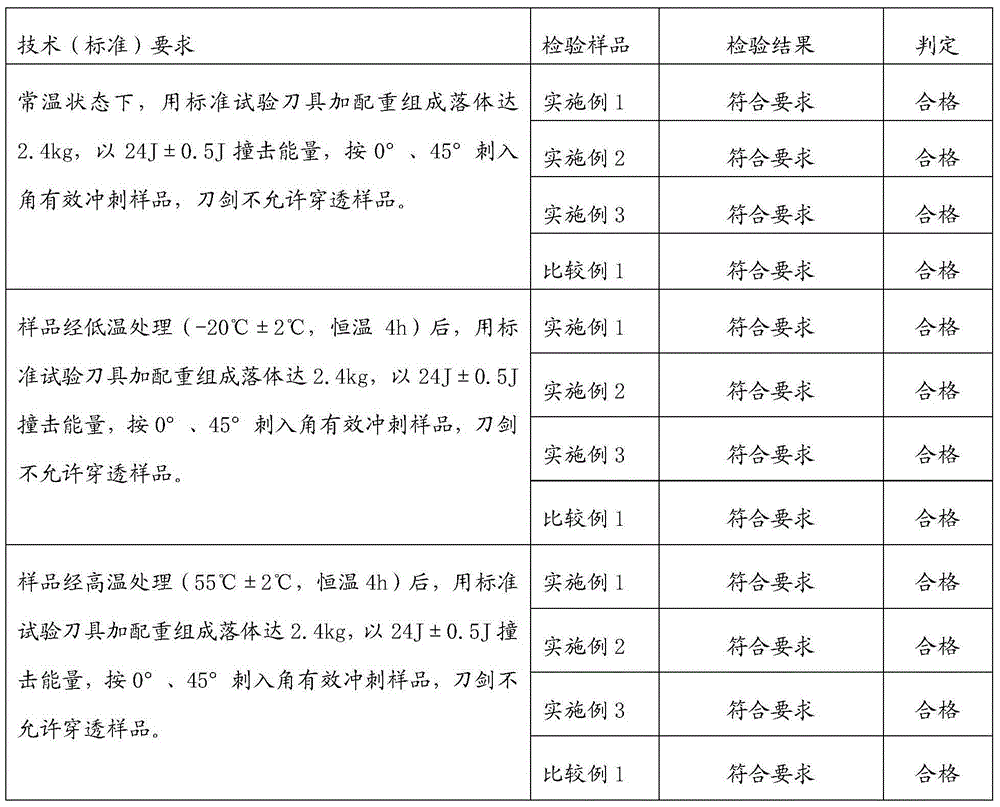

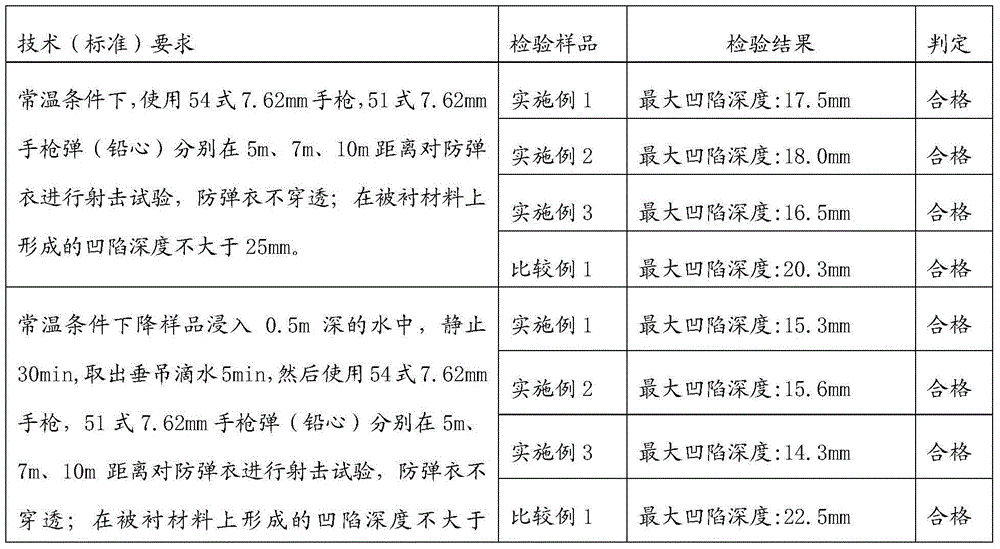

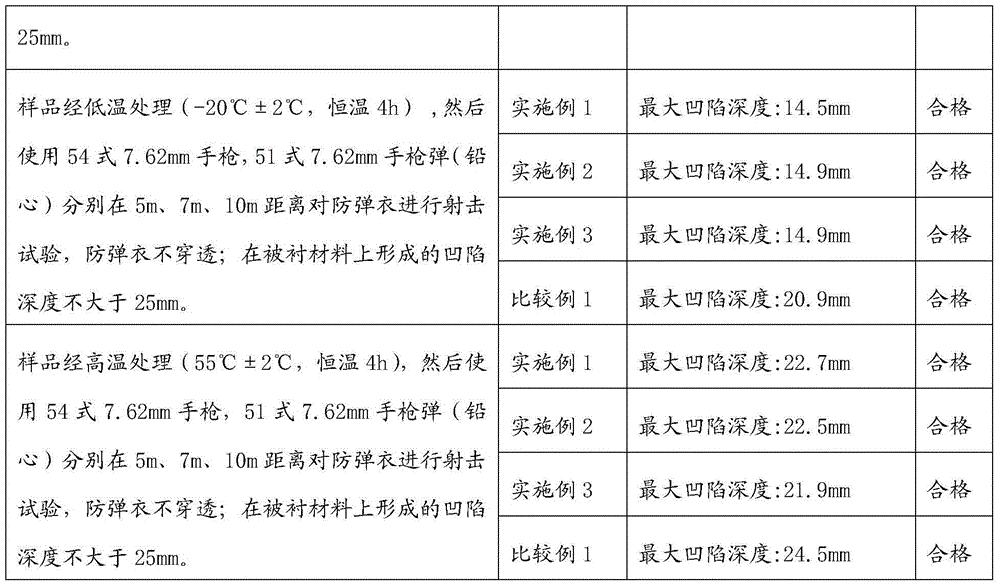

Examples

preparation example Construction

[0024] The embodiment of the invention discloses a method for preparing a bullet-proof and stab-proof clothing, comprising:

[0025] a) Spread the UHMWPE fibers evenly and preheat them;

[0026] b) Coating the adhesive on the preheated UHMWPE fiber and drying it to obtain an areal density of 135g / m 2 single-layer non-weft fabric;

[0027] c) Take 18 layers of step b to make single-layer non-weft fabrics superimposed on each other, and the fibers in adjacent non-weft fabrics are arranged at 0° / 20°, and heat-press the above-mentioned 18 layers of non-weft fabrics and 1 layer of titanium alloy sheet, Obtain the first composite layer;

[0028] d), repeating step c to obtain the second composite layer;

[0029] e) Superimpose the first composite layer, one titanium alloy layer and the second composite layer to obtain a bulletproof and stab-proof clothing, the first composite layer forms the outer layer, the titanium alloy sheet forms the middle layer, and the second The composi...

Embodiment 1

[0050] 1. Place the 400-denier RYX90 ultra-high molecular weight polyethylene fiber produced by Ningbo Rongyi Chemical Fiber Technology Co., Ltd. on the creel. The spindles on the creel pass through the cluster frame and then gather into bundles. After passing through the static electricity generation device, they enter the static electricity elimination device. , Eliminate static electricity, and then preheat the uniformly spread ultra-high molecular weight polyethylene fibers at a temperature of 50°C through a heat tunnel.

[0051] 2. Lead the preheated fiber into the gluing device and apply glue through the rubber roller. The adhesive in the rubber roller includes: 15wt% epoxy resin, 8wt% neoprene rubber, 4wt% polystyrene-butadiene Diblock copolymer, 1wt% DOA and the balance of No. 120 mineral spirits (2,3-butanedione), the prepared areal density is 135g / m 2 The non-weft cloth, the content of adhesive in the non-weft cloth is 35wt%.

[0052] 3. Take 18 layers of non-weft f...

Embodiment 2

[0056] 1. Place the 400-denier RYX90 ultra-high molecular weight polyethylene fiber produced by Ningbo Rongyi Chemical Fiber Technology Co., Ltd. on the creel. The spindles on the creel pass through the cluster frame and then gather into bundles. After passing through the static electricity generation device, they enter the static electricity elimination device. , Eliminate static electricity, and then preheat the uniformly spread ultra-high molecular weight polyethylene fibers at a temperature of 45°C through a heat tunnel.

[0057] 2. Lead the preheated fiber into the gluing device and apply glue through the rubber roller. The adhesive in the rubber roller includes: 10wt% epoxy resin, 6wt% neoprene rubber, 5wt% polystyrene-polyisoprene Diene diblock copolymer, 0.6wt% DOA and the balance of No. 120 mineral spirits (2,3-butanedione), the prepared areal density is 135g / m 2 The non-weft cloth, the content of adhesive in the non-weft cloth is 38wt%.

[0058] 3. Take 18 layers of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com