Method for reducing semiconductor device hot carrier injection damage

A technology of hot carrier and injection damage, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem of easy failure of drain terminals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

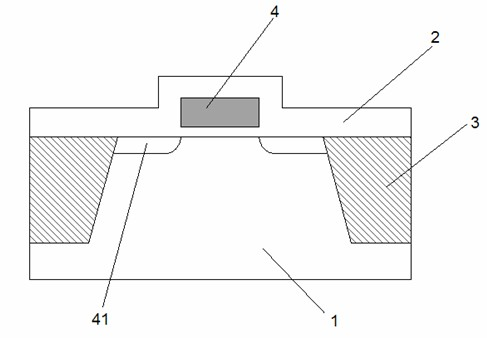

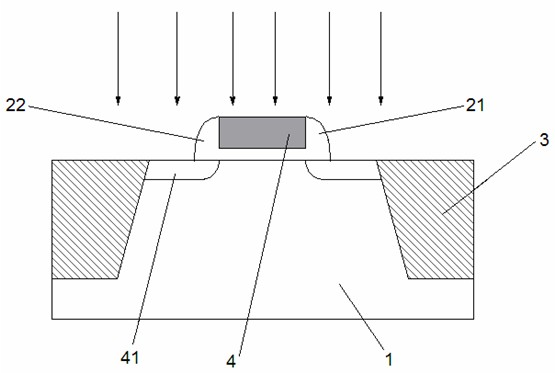

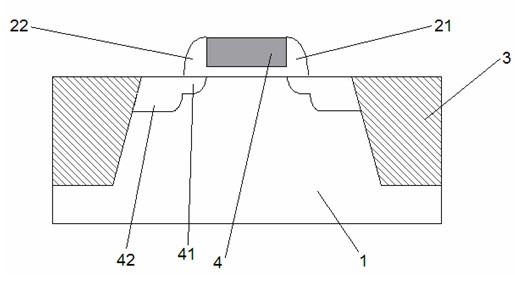

[0030] The present invention provides a method for reducing hot carrier injection damage of a semiconductor device, and a semiconductor device fabricated by using the method. In the sidewall etching process, the plasma introduction direction for etching is not perpendicular to the substrate surface, and the plasma introduction direction is inclined from the source end of the gate to the drain end; the plasma introduction direction is not perpendicular to the substrate surface The included angle is greater than 45 degrees and less than 90 degrees.

[0031] 1 and 2, the method for reducing the hot carrier injection damage of a semiconductor device of the present invention and the semiconductor device fabricated by using the method of the present invention are described in detail by taking the manufacture of a 55nm CMOS device as an example, so as to make a better understanding of the present invention, but the following examples do not limit the scope of the present invention. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com