Coil-coated spectrally selective coatings on copper or aluminum with pigments modified by aminosilane

一种氨基硅烷、涂料的技术,应用在染色有机硅化合物处理、涂层、纤维状填料等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

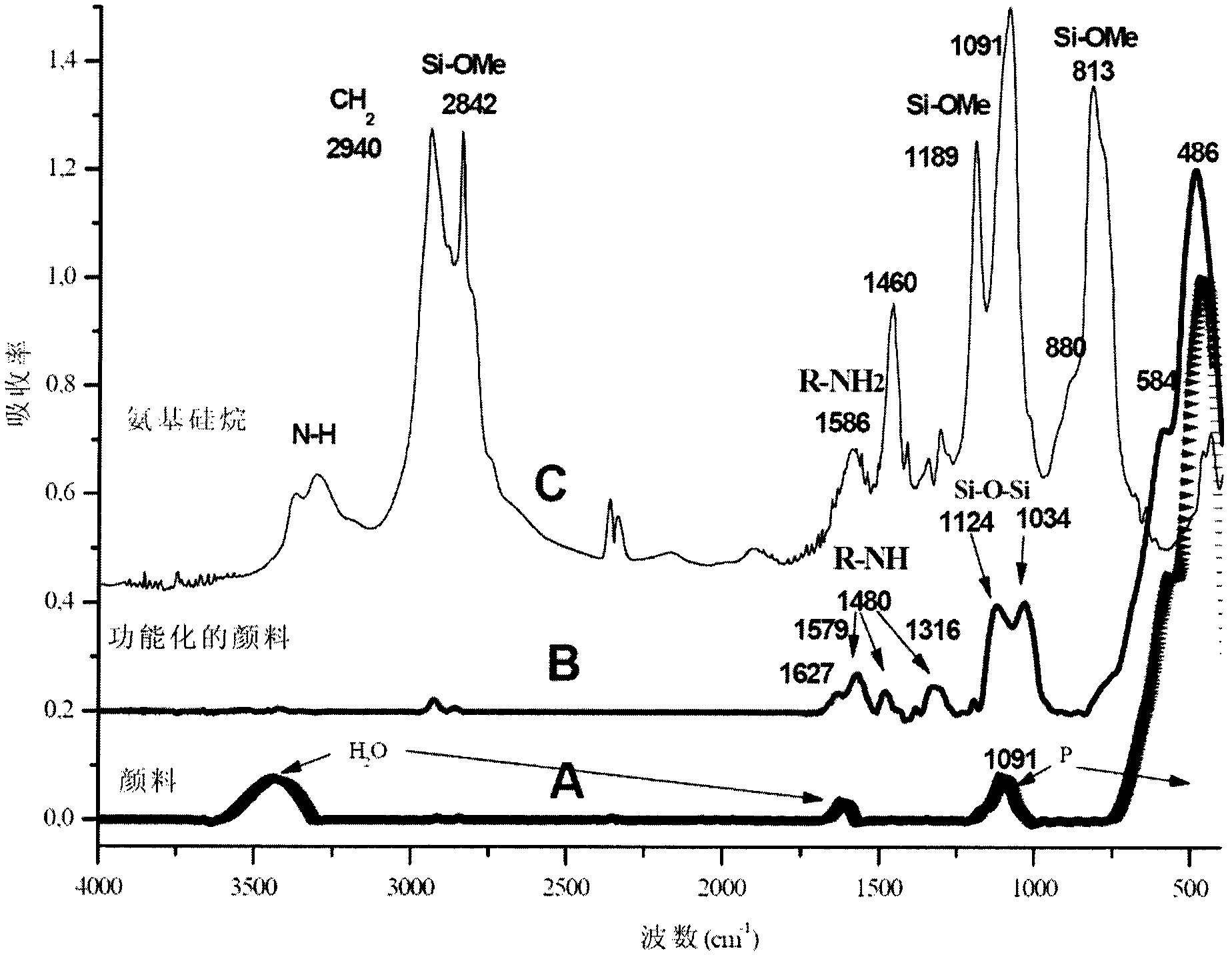

[0038] Preparation of Aminosilane Functionalized Pigments and Dispersion Systems

[0039] The aminosilane-functionalized pigment can be isolated after functionalization by filtering the dispersion, washing with a solvent, and drying the washed pigment. Other separation methods may also be used, depending on practicality and availability of other methods.

[0040] Pigment pastes can be prepared from aminosilane-functionalized pigments in the same way as pastes are prepared from other unfunctionalized pigments: the functionalization can be carried out during the preparation of the paste, preferably at the earliest possible stage, or isolated functionalized pigments.

[0041] For functionalized pigmented coatings, the pigments can be functionalized in situ during the coating process. It is recommended to perform the functionalization of the pigments at the earliest possible stage in the preparation process. Alternatively, functionalized pigment pastes or isolated functionali...

Embodiment 1

[0052] General Procedure for Preparation of 45% Pigment Paste from Aminosilane Functionalized Pigments and Silicone-Polyester Binder

[0053]

[0054]

[0055] Under continuous dispersion, the inorganic pigment was gradually added to the xylene solution of [3-(2-aminoethyl)aminopropyl]trimethoxysilane. When the addition is complete, continue the dispersion for a further 15 minutes, then add 150 g of Silikoftal under continuous dispersion Non-stick 60, then add Bentone SD-2 and further continued dispersion for 15 minutes. The resulting dispersion was ground in a sand mill at approximately 3000 RPM to a particle size <1 μm (ISO 1524). Add n-butyl acetate with continuous dispersion.

Embodiment 2

[0057] Preparation of black silicone-polyester TSSS coatings from aminosilane-functionalized pigment pastes

[0058] Prepared according to Example 1 containing 24-3060PK pigment (Ferro GmbH)

[0059] 890g

[0060] 45% black aminosilane functionalized pigment paste

[0061] Silikoftal Non-stick 60 (Evonik Tego Chemie GmbH) 110g

[0062] Silikoftal under continuous dispersion Non-stick 60 was added to a 45% black aminosilane functionalized pigment paste prepared according to Example 1 containing 24-3060 PK pigment (Ferro GmbH).

[0063] Coatings prepared in this way, suitably diluted, can be applied by coil coating or by spraying. The deposited coating is hardened by heating at 200-250°C for 10-20 minutes, or at a lower temperature for a longer time if the substrate requires a lower curing temperature.

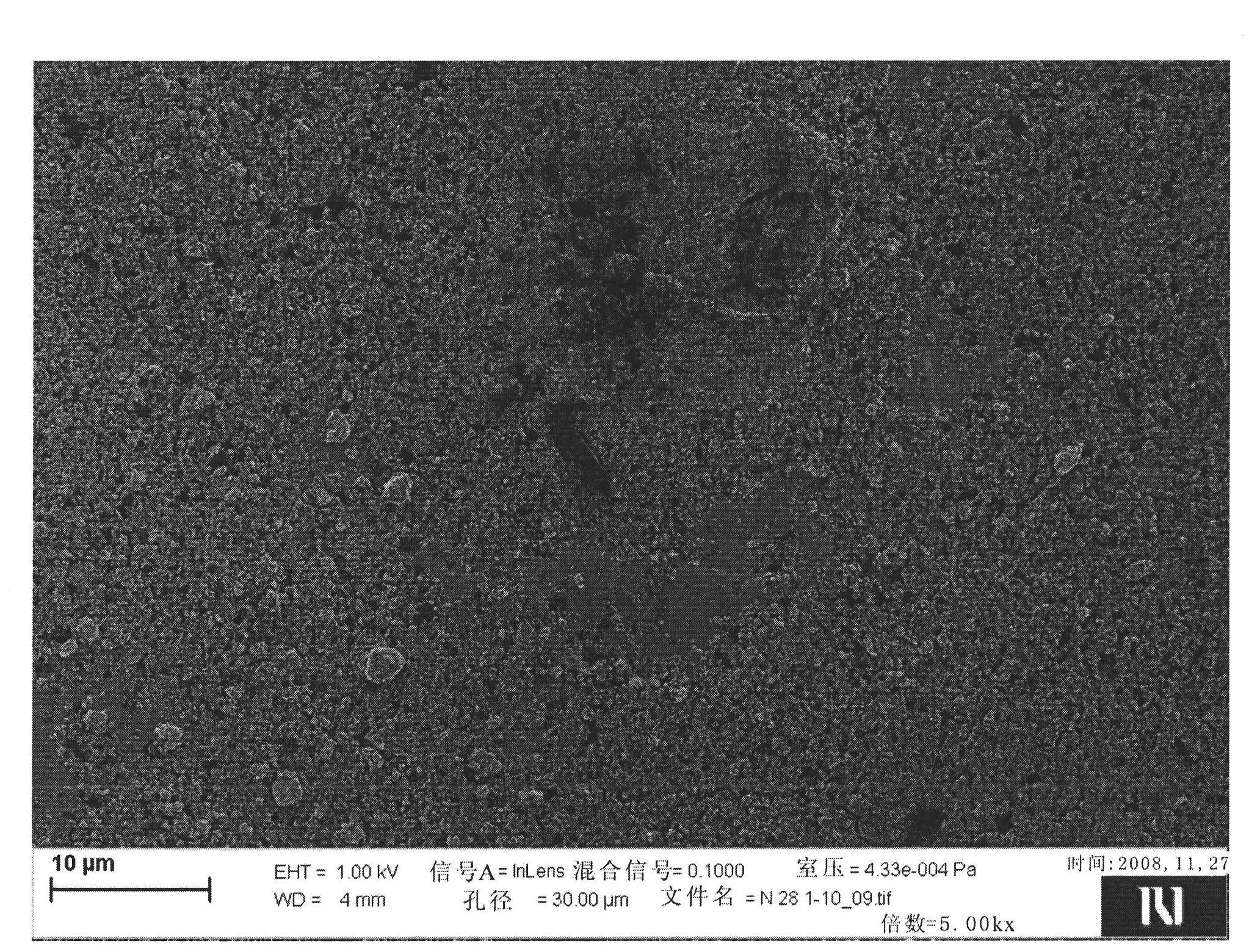

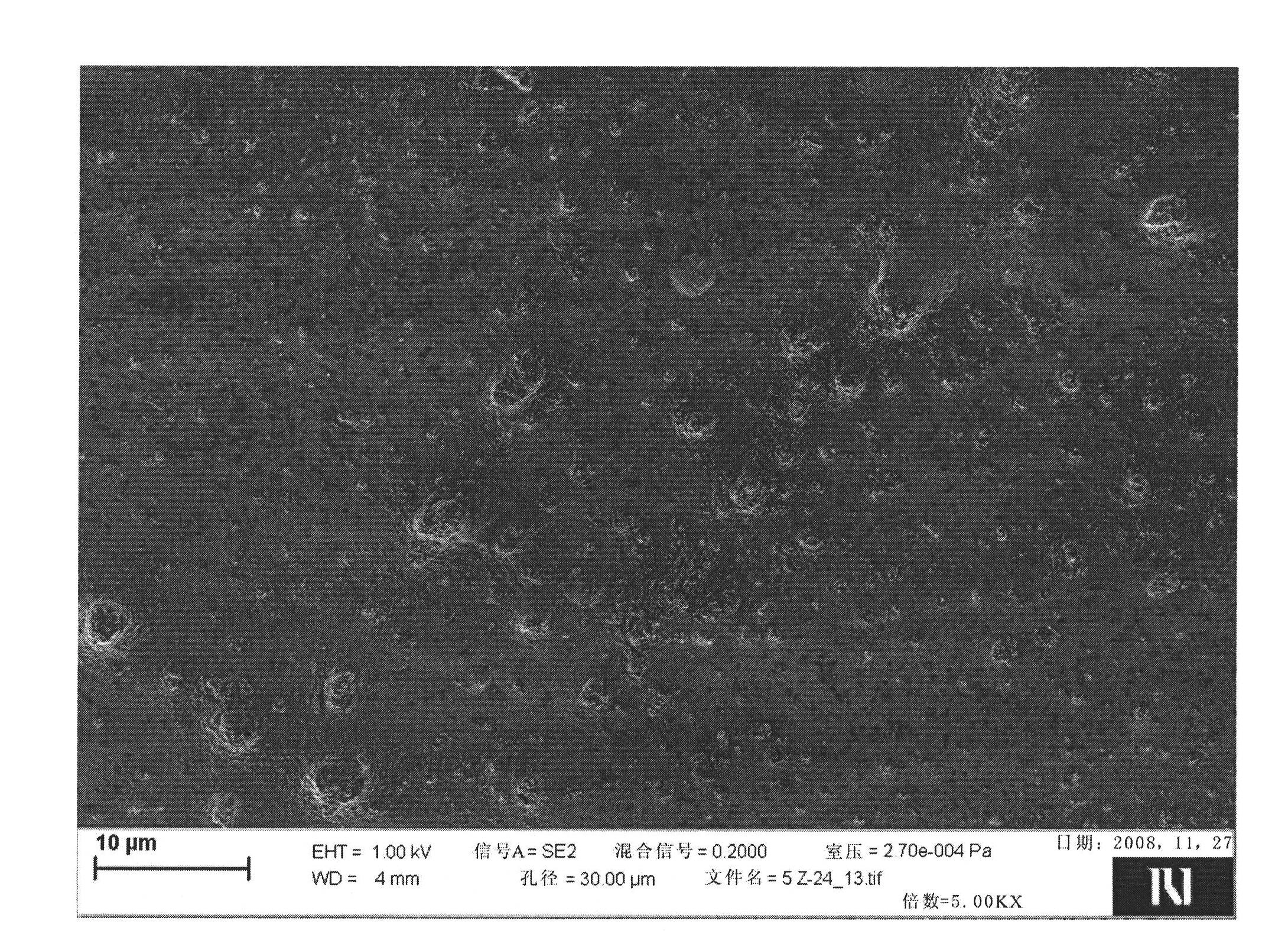

[0064] Prepared by spraying the paint onto a copper substrate with an equivalent thickness of 1g / m 2 The coating has ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solar absorptance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com